Contents

412721 3

Contents

1Important Information....................................................................................................................4

1.1 General Information .........................................................................................................................4

1.2 Target Groups..................................................................................................................................4

1.3 Intended Use....................................................................................................................................4

1.4 Use for an Unauthorized Purpose....................................................................................................4

1.5 Safety Devices.................................................................................................................................5

1.6 Meaning of the Warning notes.........................................................................................................5

1.7 Product Standards, Safety Regulations...........................................................................................5

2Basic Safety Instructions ..............................................................................................................6

2.1 General Information .........................................................................................................................6

2.2 Electricity..........................................................................................................................................6

2.3 Mechanical Systems........................................................................................................................6

2.4 Hazardous Substances....................................................................................................................7

2.5 High Temperatures ..........................................................................................................................7

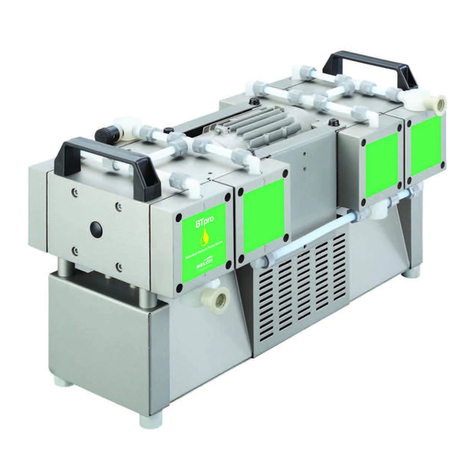

3Description .....................................................................................................................................8

3.1 Design..............................................................................................................................................8

3.2 Principle of Operation.......................................................................................................................8

3.3 Gas ballast.......................................................................................................................................8

3.4 Areas of Application.........................................................................................................................8

3.5 Pump head circuitry .........................................................................................................................9

3.6 Materials of the medium-affecting pump parts.................................................................................9

3.7 Scope of Delivery.............................................................................................................................9

3.8 Accessories......................................................................................................................................9

3.8.1 Connection variants A –K..............................................................................................................10

4Technical Data..............................................................................................................................11

4.1 Dimensions ....................................................................................................................................11

4.2 Intake Pressure / Pumping Speed –Diagram................................................................................11

4.3 Device Data....................................................................................................................................12

5Installation and Operation...........................................................................................................13

5.1 Unpacking......................................................................................................................................13

5.2 Installation and Connection............................................................................................................13

5.3 Operation .......................................................................................................................................13

5.4 Storage...........................................................................................................................................13

5.5 Scrap Disposal...............................................................................................................................13

6Maintenance and Servicing.........................................................................................................14

6.1 General Requirements...................................................................................................................14

6.2 Maintenance Performed by the User .............................................................................................14

6.2.1 Disassembly...................................................................................................................................15

6.2.2 Assembly........................................................................................................................................15

6.2.3 Test................................................................................................................................................16

6.3 Maintenance by the Manufacturer..................................................................................................16

6.4 Damage Report..............................................................................................................................16

7Troubleshooting...........................................................................................................................17

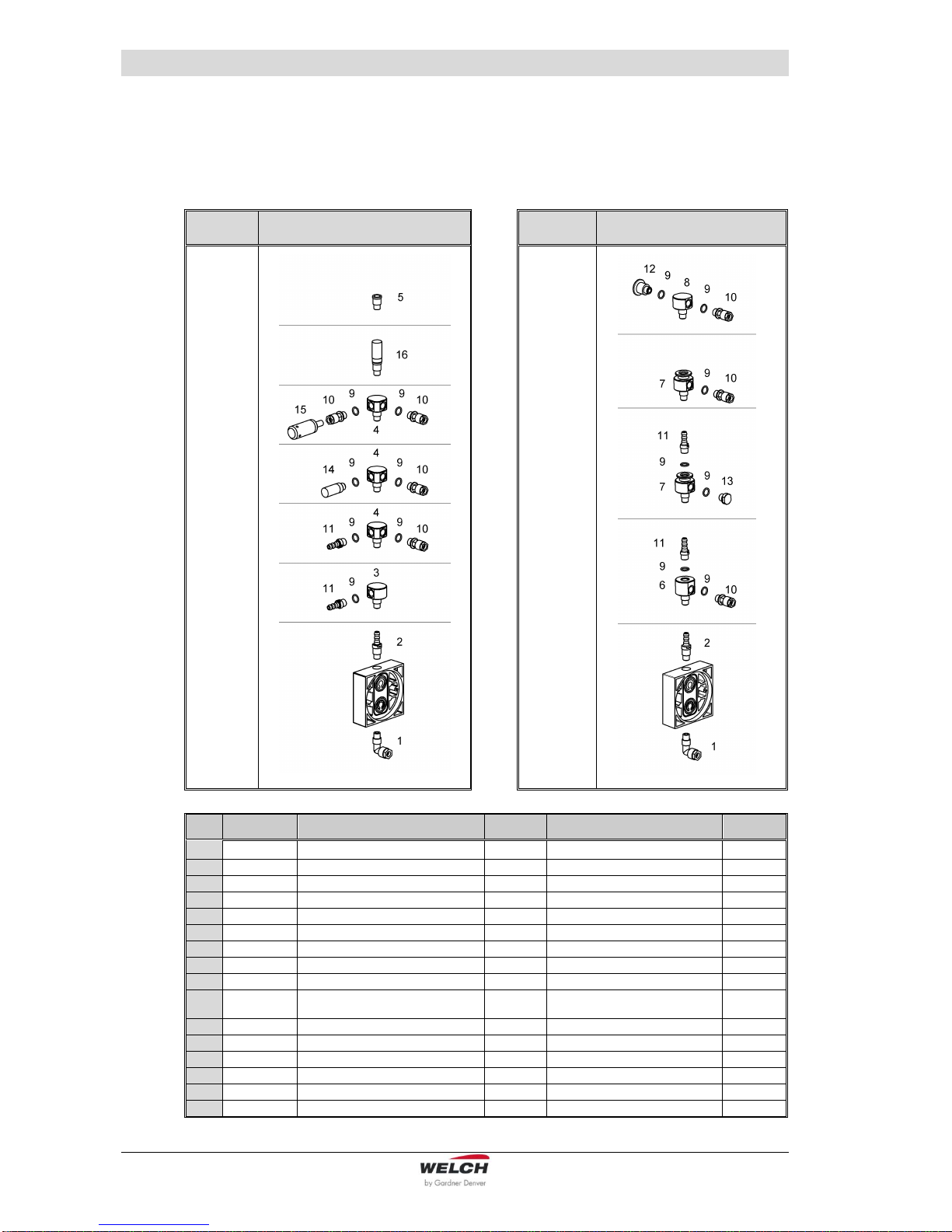

8Spare Parts Overview ..................................................................................................................18

8.1 Service kit.......................................................................................................................................18

8.2 Spare parts view ............................................................................................................................19

8.2.1 Spare parts list diaphragm pumps MP 601 E.................................................................................20

8.2.2Spare parts list diaphragm pumps MP 301 Z.................................................................................21

8.2.3 Spare parts list diaphragm pumps MPC 601 E..............................................................................22

8.2.4 Spare parts list diaphragm pumps MPC 301 Z ..............................................................................23

8.2.5 Spare parts list diaphragm pumps MPC 601 E-X2, MPC 301 Z-X2...............................................24

-Instructions for certification - Diaphragm Pumps MPC -

for use in Zone 2 in accordance with device category 3 per ATEX Directive 2014/34/EU

(Page 1 - 3)

- EC Declaration of Conformity