Contents

2561-67 3

Contents

1Important Information.............................................................................................................4

1.1 General Information..................................................................................................................4

1.2 Target Groups...........................................................................................................................4

1.3 Intended Use.............................................................................................................................4

1.4 Use for an Unauthorized Purpose ............................................................................................4

1.5 Safety Devices..........................................................................................................................5

1.6 Meaning of the Warning notes..................................................................................................5

1.7 Product Standards, Safety Regulations....................................................................................5

2Basic Safety Instructions.......................................................................................................6

2.1 General Information..................................................................................................................6

2.2 Electricity...................................................................................................................................6

2.3 Mechanical Systems.................................................................................................................6

2.4 Hazardous Substances.............................................................................................................7

2.5 High Temperatures ...................................................................................................................7

3Description ..............................................................................................................................8

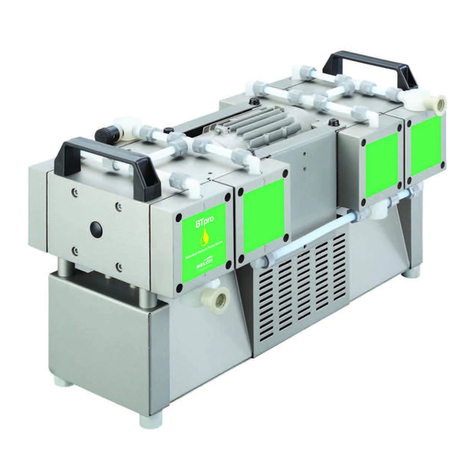

3.1 Design.......................................................................................................................................8

3.1.1 Connections - Suction-/Pressure side ......................................................................................8

3.1.2 Connecting to the electricity supply ..........................................................................................8

3.1.3 Display –Vacuum Regulator ....................................................................................................8

3.2 Additional protection measures against liquids in the pump.....................................................9

3.2.1 Condensate separator (Suction side) .......................................................................................9

3.2.2 Cold trap (Suction side) ............................................................................................................9

3.3 Areas of Application..................................................................................................................9

3.4 Materials of the medium-affecting pump parts..........................................................................9

3.5 Scope of Delivery....................................................................................................................10

3.6 Accessories.............................................................................................................................10

4Technical Data.......................................................................................................................11

5Installation and Operation....................................................................................................12

5.1 Unpacking...............................................................................................................................12

5.2 Setting up and connecting ......................................................................................................12

5.2.1 Setting up................................................................................................................................12

5.2.2 Connecting..............................................................................................................................12

5.2.2.1 Electrical Connection ..............................................................................................................12

5.2.2.2 Vacuum connection (Suction side) .........................................................................................12

5.2.2.3 Exhaust connection (Pressure side).......................................................................................13

5.3 Operation ................................................................................................................................13

5.3.1 Start-up ...................................................................................................................................13

5.3.2 Decommissioning....................................................................................................................13

5.4 Storage....................................................................................................................................13

5.5 Scrap Disposal........................................................................................................................13

6Maintenance and Servicing..................................................................................................14

6.1 Maintenance Performed by the User......................................................................................14

6.2 Maintenance by the Manufacturer ..........................................................................................14

6.3 Damage Report.......................................................................................................................14

7Troubleshooting....................................................................................................................15

8Spare Parts Overview...........................................................................................................16

8.1 Kit –Order numbers................................................................................................................16

8.2 Spare parts view / Parts lists 2561 .........................................................................................17

8.3 Spare parts view / Parts lists 2567 .........................................................................................18

EC Declaration of Conformity