Page 7of 10

These welding machines consist of a drooping specification, and are suitable for welding with alternating current

using coated electrodes (E 43 R type) based on t

he diameters given on the data plate.

To switch on the welding machine operate the main switch (Fig. B-1).

The intensity of the supplied welding current can be adjusted continuously, by means of a manually operated

magnetic shunt (Fig. B-2).

CHECK THE WELDING MACHINE MODEL

N.B. In the case of a welding machine with switch, current adjustment should be carried out with the main switch (Fig.

B-1) in the O position (off).

The value of the current setting, (I2) can be read in Amps on the graduated scale (Fig. B-4) on the top or side panel

of machines where it is provided.

THERMOSTATIC

PROTECTION

This welder is automatically protected from thermic overheating (thermostat

automatic re-start). When the windings reach performance temperature, the

protection cuts off the supply circuit, igniting the yellow lamp on the front panel (B-5).

After a few minutes cooling the protection will reopen the supply line and turn off the

yellow lamp. The welder is ready for further use.

WELDING

Use electrodes suitable for working in alternating current. The welding current must

be regulated according to the diameter of the electrode in use and the type of the

joint to be carried out: see below the currents corresponding to various electrode

diameters:

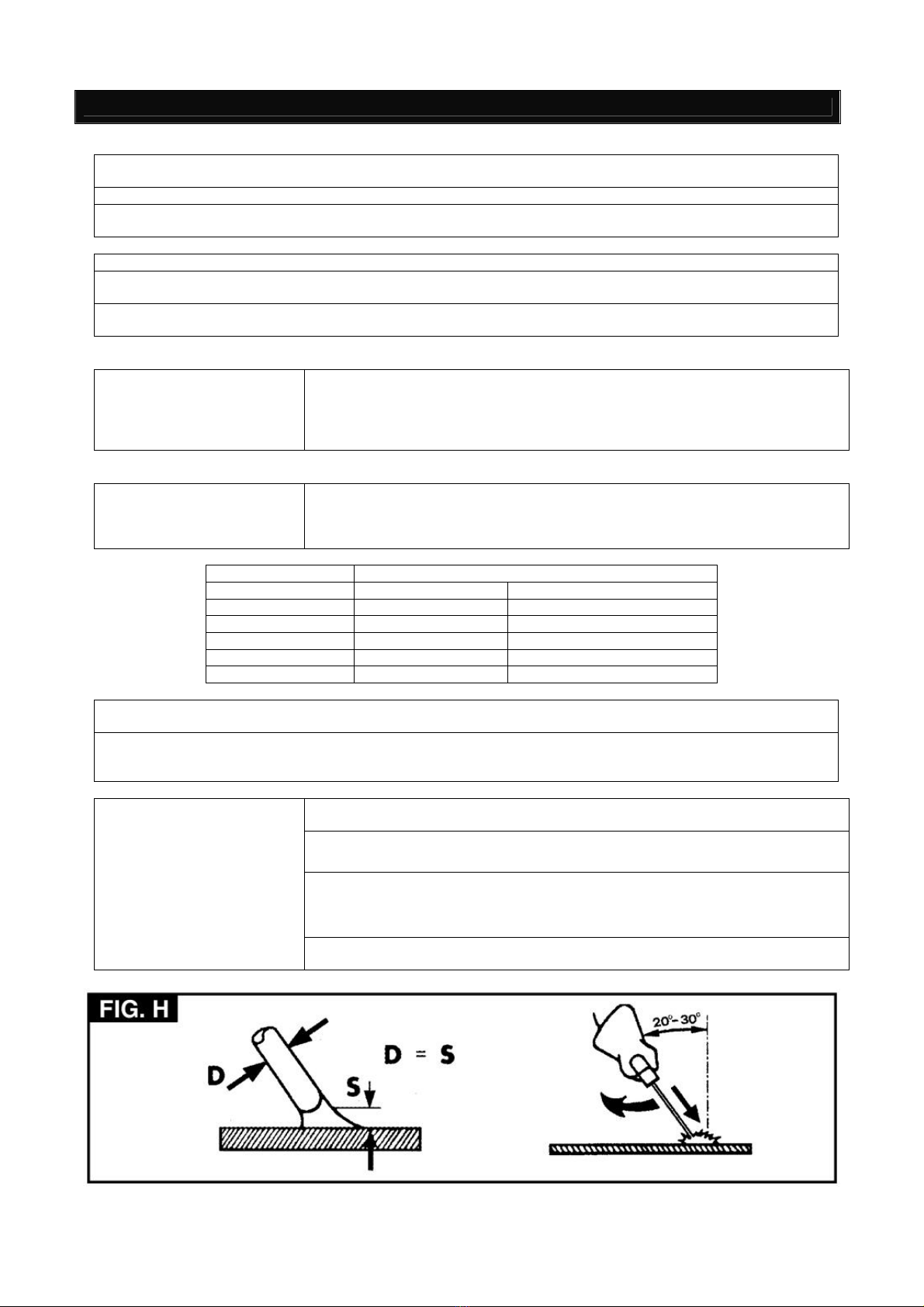

ø Electrode (mm) Welding current (A)

min max

1.6 25 50

2 40 80

2.5 60 110

3.2 80 160

4 120 200

The user must consider that, according to the electrode diameter, higher current values must be used for flat welding,

whereas for vertical or overhead welds lower current values are necessary.

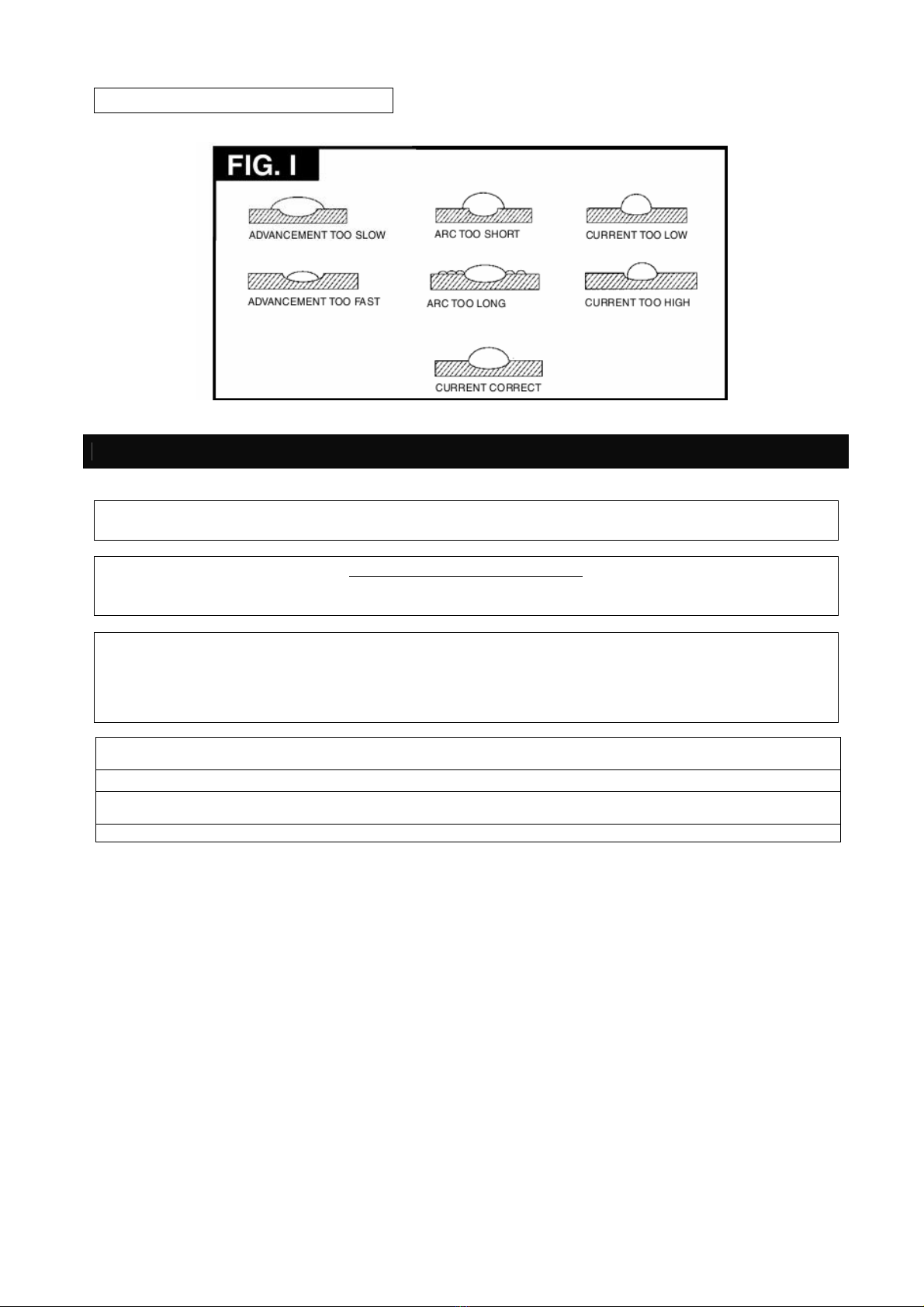

In addition to being determined by the selected current intensity, the mechanical characteristics of the welded joint is

determined by the other welding parameters i.e. arc length, working rate and position, electrode diameter and quality

(to store the electrodes correctly keep them dry and protected by suitable packaging or containers).

Holding the mask IN FRONT OF THE FACE, strike the electrode tip on the work

piece as if you were striking a match. This is the correct strike-up method.

WARNING: DO NOT HIT THE ELECTRODE ON THE WORK PIECE, THIS COULD

DAMAGE THE ELECTRODE AND MAKE STRIKE-UP DIFFICULT.

As soon as the arc is ignited, try to maintain a distance from the work piece equal to

the diameter of the electrode in use. Keep this distance as constant as possible for

the duration of the weld. Remember that the angle of the electrode as it advances

should be of 20-30 degrees (Fig.H).

WELDING PROCEDURE

At the end of the weld bead, bring the end of the electrode backward, in order to fill

the weld crater, quickly lift the electrode from the weld pool to extinguish the arc.

SECTION 8 : WELDING: DESCRIPTION OF THE PROCEDURE