SERVICE

INSTRUCTIONS

NOTE:

All monitors are equipped with automatic degaussing

coils

(L701) which demagnetize the picture tube

every

time

the monitorIs turned

on

after

being

off

for a minimum

of

5 minutes. Should any part

of

the chassis

become magnetized

It

will be necessary

to

degauss the affected area with a manual degaussing coil. Move

the coil

slowly

around the

CRT

face area and all surrounding metal parts. Then slowly withdraw for adistance

of

6 feet before turning off.

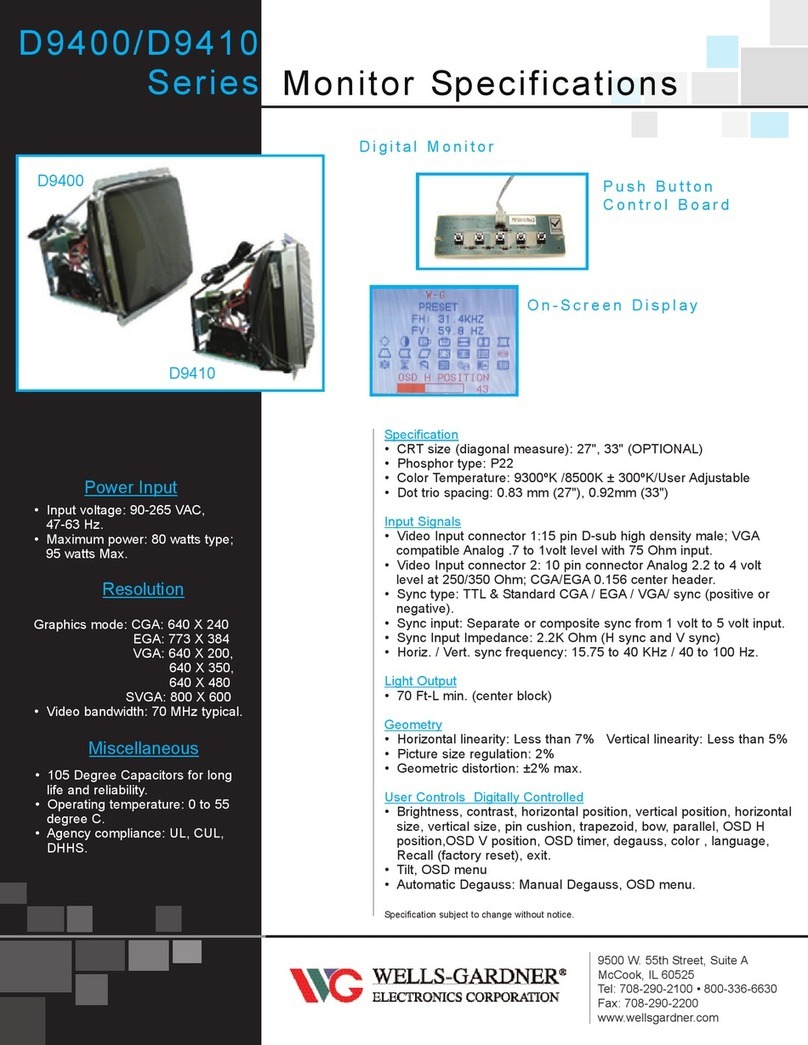

Horizontal vs. Vertical:

Some models have the picture tube mounted vertically rather than horizontally. That

Is,

the picture tube Is

mounted in the frame such that the long dimension

of

the tube Is up and down. Examples

of

this include(but

are not

limited

to) Models

K4951,

K4952,

K4956,

K4956R, and

K4961

as

In

the pictures on the bottom

of

the

front cover. Other than the physical orlentatlon

of

the picture tube, there Is

no

electrical difference between

these models and their horizontal counterparts. The same circuits, the vertical circuits, produce and control

deflection along the short dimension

of

the tube In all models.

The same circuits, the horizontal circuits, produce and control deflection along the long dimension

of

the

tube

In

all models.,Therefore, wherever "vertical" appears in this manual

or

on the monitor,

it

refers to the short

dimension

of

the picture tube; wherever "horizontal" appears,

lt

refers tothe long dimension

of

the picture tube.

1.0

BLACK

LEVEL CONTROL ADJUSTMENT

This control has been set at the factory and should not need further at-

tention. However, when the game is connected 3 slight adj1Jstment

of

VR201

may

be

necessary to obtain the proper black level (the black

portion

of

the picture just extinguished).

2.0 VERTICAL SIZE (HEIGHT)

Location

of

this control is shown in Fig.

1.

This control must

be

adjust-

ed

slowly,

If

necessary, until the picture or test pattern attains the cor-

rect vertical proportions.

NOTE:

This adjustment interactswith thevertical dampingadjustment

described in the paragraph below. Umay

be

necessary to readjust the

vertical size after the vertical damping control has been adjusted.

3.0 VERTICAL DAMPING

Adjustment

of

this control is required only if the monitoris being used

with a game in which the top several raster lines are visible

on

the

screen. Adjust the vertical damping control for uniform spacing

of

the

top raster lines.

4.0 CIRCUIT PROTECTION

A 4.0A ptgtall fuse, mounted on the Main Board has been provided to

protect the Power Output Circuit.

5.0 FOCUS

Adjust the Focus control, located on the

HV

unit(T352), for maximum

over-all definition and fine picture detall.

6.0 HORIZONTAL

HOLD

CONTROL ADJUSTMENT, VR351

(See

Fig.

1a

or

1b)

A warm-up period

of

at

least five minutes should

be

allowed before

alignment is carried out. With the monitor being driven from the

game signal, short

TP601

to

TP31.

Adjust

VR351

until the picture

stops sliding horizontally. Remove the short.

7.0

HORIZONTAL

VIDEO POSITION

If

the video is

off

center on the raster, some compensation can be

made by adjusting

this

control.

8.0 VERTICAL RASTER POSITION ADJUSTMENT

If

the video Is

off

center vertically, (short dimension

of

picture tube)

some compensation can be made by turning the vertical raster posl-

tlon control.

9.0 HORIZONTAL RASTER POSITION

ADJUSTMENT

If the video

Is

off

center horizontally (long dimension

of

the picture

tube), somecompensationcan be made by moving thehorizontal ras-

ter position adjustment jumper to either positions

"A"

or

"L".

NOTE:

This adjustment Is not provided on Model

K4903.

10.0 HORIZONTAL WIDTH ADJUSTMENT

The

horizontal width coll ls a hexagonal tuning tool adjustment. This

control must

be

adjusted slowly,

If

necessary, until the picture

or

test pattern attains the correct horizontal proportions.

3

...

..

,

..

ltt:D CUTO,ir

...

cvro,,:-\

ILU

CUTOFF\

'\

.

..

...

,m

DftlVE

_,,

WIDTH

COIL

H01tl2 Yt:ltT Yt:ltT

VIIIT

vt:ltT

HOllll

SClttEN

CIENT!ltlNG

Silt:

HOLD DAMPING IIASTl!:lt ltASTl!lt

POI.

SMln-lf

*NOT

ON

MOOl!L

IC

◄

IOl

ltl!O

CUTOFI'

...

""

...

...

Figure 1(a)

Gllfll

ltro

ORIYI: O!tlVE

..

,.,

WHEN USING

COM-

POSff'E

SVIIC

USE

HOltllONTAL

STNC

INPUTS.

""--·

ILIC

LIVl!L

At"""

,...,

HOltlZ

WIOTH

,~,

HOltlZ

YIEIIT

Yt:IIT

\ll!ltT

VlltT

ltOltll

SCltHN

CINTOt"'°

SIU

NOLD

OAIIIIP-

ltAITt:lt

IIAITl!lt

P'OS.

IHln

Flgure

1(b)