WerkMaster Scarab User manual

Handheld Variable Speed Grinder & Polisher

The Ideal Machine for Countertops, Floors,!

Stairs and Ledges

WerkMaster Grinders & Sanders Inc.

6932 Greenwood Street,

Burnaby, BC

V5A 1X8

604-629-8700

1-866-373-WERK

sales@werkmaster.com

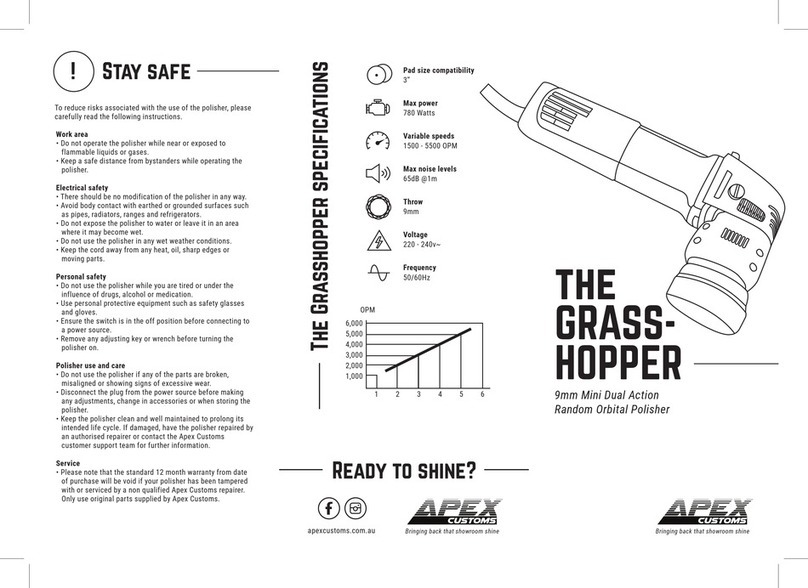

Footprint: IN (cm)

12x8x7 (31x20x18)

Disc Size: IN (cm)

3 (7.6)

Weight: LBS (Kg)

20 (9) w/o drive unit

Vacuum Req: CFM

100

SPECS

Use on concrete, stone,

terrazzo, and VCT tile.

Go from dry grinding to wet polishing

and cutting with the addition of our

simple to connect Water Feature.

Easily gets in to hard to reach and

small spaces.

sales@werkmaster.com

support@werkmaster.com

604-629-8700

1-866-373-WERK (9375)

Use with WerkMaster 3” (76mm) full

plate diamond abrasive tooling, resins

and buffing pads. Versatile, quick, and

easy to install and remove.

FULL PLATE TOOLING

Gets up to 1/8”

of the wall!

0120

!!

WerkMaster Grinders and Sanders Inc.

6932 Greenwood Street, Burnaby, BC V5A 1X8

tel: 604.629.8700 | toll free: 1.866.373.WERK | fax: 604.444.4231

www.werkmaster.com | email: support@werkmaster.com

!

!

!

!

!

!

!

!

!

!

!

!!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

OPERATOR’S MANUAL

IMPORTANT: Read before using your new Scarab™

© Copyright 2013

!!

LIABILITY LIMITATIONS

The remedies of the user set forth under provisions of warranty outlined at the

end of this manual are the exclusive and total liability of WerkMaster Grinders &

Sanders Inc. with the respect to their sale or the equipment and service furnished

hereunder, in connection with the performance or breach thereof, or from the

sale, delivery, installation, repair or technical direction covered by or furnished

under the sale, whether based on contract, warranty, negligence, indemnity, strict

liability, or otherwise shall not exceed the purchase price of the unit of equipment

upon which such liability is based.

WerkMaster will not in any event be liable to the user, any successors in interest

or any beneficiary or assignee relating to this sale for any consequential,

incidental, indirect, special or punitive damages arising out of this sale or any

breach thereof, or any defects on, or failure of, or malfunction of the equipment

under this sale based upon loss of use, lost profits or revenue, interest, lost

goodwill, work stoppage, impairment of other goods, loss by reason of shutdown

or non-operation, increased expenses of operation of the equipment, cost of

purchase or replacement power of claims of users or customers of the user for

service interruption whether or not such loss or damage is based on contract,

warranty, negligence, indemnity, strict liability, or otherwise.

WerkMaster reserves the right to modify, alter and improve any part or parts

without incurring any obligation to replace any part or parts previously sold

without such modified, altered or improved part or parts.

No person is authorized to give any other warranty or to assume any additional

obligation on WerkMaster’s behalf unless made in writing and signed by an

officer of WerkMaster.

USE ONLY GENUINE WERKMASTER PARTS AND ACCESSORIES FOR

YOUR OWN SAFETY, THE SAFETY OF OTHERS AND THE LIFE OF YOUR

MACHINE.

!"#$%&!$'()*%+,%-))

Page!III!)

.!+&#+&()

)

Introduction)/////////////////////////////////////////////////////////////////////////////////////////////////////)0)

*123456)768294:;4<5)//////////////////////////////////////////////////////////////////////////////////////////)0!

(:624=421;4<58)////////////////////////////////////////////////////////////////////////////////////////////////////)0!

(1=6;>)"9621?;4<58)/////////////////////////////////////////////////////////////////////////////////////////////)@!!

Personal!Safety!.........................................................................................................!2!

Physical!and!Mental!Fitness!......................................................................................!2!

Safe!Operating!Distance!...........................................................................................!2!

Wrok!Safety!AeaSafe!................................................................................................!3!

Safety!Rules!..............................................................................................................!3!

Modifications!............................................................................................................!3!

%;;12345A)(2191B);<)794C69)/////////////////////////////////////////////////////////////////////////////////)D!

E15FG6)%886HBG>)I58;9?2;4<58)////////////////////////////////////////////////////////////////////////////)J!

!:;4<51G)E15FG6)%886HBG>)I58;9?2;4<58)///////////////////////////////////////////////////////////////)K!

"96LM945F45AN"<G48345A)I58;9?2;4<58)////////////////////////////////////////////////////////////////////)O!

*123456)!:691;4<5)///////////////////////////////////////////////////////////////////////////////////////////)P!

.315A45A)(;15F19F)&<<G45A!.........................................................................................!9!

.315A45A)"G?A)Q+)M<)&<<G45A!.....................................................................................!0R!

%FS?8;45A)7?8;)(T49;!..................................................................................................!00!

(6;;45A)(:66F!............................................................................................................!00)

#FA45A!........................................................................................................................!00!

U12??H!......................................................................................................................!0@!

V1;69)W61;?96)"<9;)//////////////////////////////////////////////////////////////////////////////////////////)0@)

.G61545A)15F)*145;651526)///////////////////////////////////////////////////////////////////////////////)0X!

(;<91A6)///////////////////////////////////////////////////////////////////////////////////////////////////////////)0X!

&9<?BG683<<;45AN&623)(?::<9;)/////////////////////////////////////////////////////////////////////////)0X!

!:;4<51G)%2688<9468)/////////////////////////////////////////////////////////////////////////////////////////)0D!

#Y:G<F6F)U46Z)/////////////////////////////////////////////////////////////////////////////////////////////////)0[)

"19;8)-48;)/////////////////////////////////////////////////////////////////////////////////////////////////////////)0J!

V19915;>)/////////////////////////////////////////////////////////////////////////////////////////////////////////)0K!

!:691;4<5)15F)(1=6;>)M?4F6)//////////////////////////////////////////////////////////////////////////////)0P!

!

!

!"#$%&!$'()*%+,%-))

Page!1!)

!!

INTRODUCTION

Congratulations on your purchase of a WerkMaster Scarab. WerkMaster

machines allow professional surface prep, polishing, grinding, edging, buffing

and restoration of virtually any surface material, including concrete, terrazzo,

stone, vinyl, and hardwood. This manual is provided to assist you in the

operation and maintenance of your WerkMaster Scarab.

!

MACHINE DESCRIPTION

WerkMaster machines include the Scarab, Termite XT, Viper XT, Raptor XT,

TITAN XT, COLOSSOS XT models. To see the complete family of WerkMaster

machines visit our website at www.werkmaster.com.

Scarab

•Ideal machine for floors, walls, stairs, risers, ledges and countertops

•Grinds, strips, sand, polishes, buffs, burnishes and edges

•Edges right up to the wall, riser, and countertop

•Excellent for concrete, stone, hardwood, terrazzo and vinyl tile

•Handheld for countertops, walls, risers and ledges; use with removable,

upright handle on floors and stairs

•90° head rotation is designed to get into tight places and small spaces

•Works with the Milwaukee, Metabo, Flex, DeWalt and Alpha variable speed

polishers

•The Octi-Disc™ self-balancing 5 head system is used with our ULTRA-FLEX

Plug ‘N Go diamond abrasive tools or standard 3” (76 mm) polishing pads

!

!

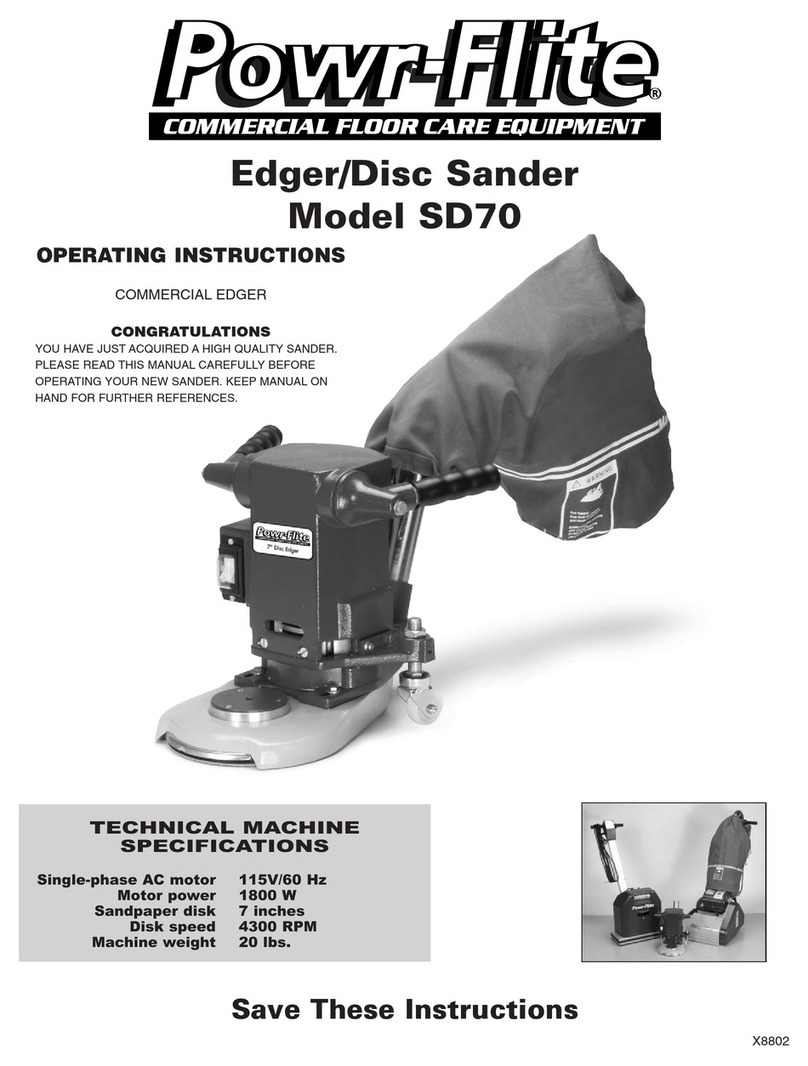

SPECIFICATIONS

MODEL

DIMENSIONS l x w x h

WEIGHT

Scarab

in 12 x 8 x 7

lbs 22

cm 31 x 20 x 18

kg 10

!

!

!

!

!

!

!

!

!

!

!

!

!"#$%&!$'()*%+,%-))

Page!2!)

!!

SAFETY PRECAUTIONS

!

!

!

!

!

Read this manual and all safety precautions before attempting to operate your

WerkMaster Scarab. Failure to follow the safety precautions could result in

electric shock, fire and/or serious injury.

The term “variable speed grinder/polisher” refers to your main-operated (corded)

power tool or battery operated (cordless) power tool. ALWAYS refer to the

variable speed grinder/polisher manual when using the Scarab.

!

!

•Wear eye and ear protection at all times when operating WerkMaster

machines. Use only ANSI/OSHA approved safety glasses to help

prevent eye injury.

•Wear appropriate clothing and footwear when operating WerkMaster

machines. Do not wear loose clothing or jewelry that can become

entangled in moving parts.

•Safety equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce

personal injuries.

•Avoid accidental starting. Ensure the switch is in the OFF position before

plugging in. Do not carry power tools with your finger on the switch or

plug in power tools that have the switch on.

•Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

•Do not overreach. Keep proper footing and balance at all times.

•Always use a vacuum. Ensure the variable speed grinder/polisher is

properly connected to the Scarab and follow all operating procedures.

•Keep handles dry, clean and free from oil and grease.

!

•Never operate WerkMaster machines under the influence of drugs or

alcohol, when taking medications that impair the senses or reactions, or

when excessively tired or under stress.

!

•WerkMaster machines are designed to be operated by one person at a

time. Maintain a safe operating distance to other persons. Keep

bystanders a safe distance away during operation by blocking off the

work area in all directions with roping, safety netting, or other material.

Failure to do so may result in someone being injured by flying debris or

being exposed to harmful dust and noise.

•Maintain a safe operating distance from flammable materials. Sparks

from the cutting action of WerkMaster machines may ignite flammable

materials or vapors.

!

!

Personal Safety

Physical and

Mental Fitness

Safe Operating Distance

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! )V%$+I+M)

!"#$%&!$'()*%+,%-))

Page!3!)

!!

!

!

•Keep work area clean and well lit.

•Turn off the WerkMaster before disconnecting power.

•DO NOT disconnect power by pulling the cord. To disconnect power,

grasp the plug, not the cord. To remove twist-lock plugs, push in and

turn clockwise to engage, and turn counter-clockwise and pull to

remove.

!

•ALWAYS refer to the variable speed grinder/polisher manual for safe

operation

•DO NOT let comfort or familiarity with this tool (gained from repeated

use) replace strict adherence to polisher safety rules. If you use this tool

unsafely or incorrectly, you may suffer serious personal injury.

•Running accessories over rated speeds may cause injury.

•Firmly secure any loose surface before operating the Scarab. Do not use

your hand or body to secure loose surfaces.

•Hold the tool firmly with both hands. Do not drop. When using either

the handheld handle, or the full extension articulating handle assembly,

be sure to keep the Scarab level or flat with the surface, using smooth

and continuous movement. Avoid objects projecting out of the solid

surface you are working on as they may cause damage to the tooling.

•Keep hands away from rotating parts.

•When sanding metallic surfaces, the operator should watch for

flying sparks. Hold the tool so that the sparks fly away from you, other

persons and flammable materials.

•DO NOT leave the tool running.

•DO NOT touch the work surface immediately after operation; it may be

hot.

•Pay attention; the Plug ‘N Go tooling plates may continue to rotate after

the tool is switched off.

•Ventilate your work area adequately when operating a Scarab.

•Use of this tool to sand or grind could expose user to dust containing

hazardous substances. Use appropriate respiratory protection.

!

•DO NOT modify WerkMaster machines. Modifications will void the

warranty and may result in injury to persons and damage to the

machine.

!

!

!

!

!

!

!

!

!

Work Area Safety

Safety Rules

Modifications

!"#$%&!$'()*%+,%-))

Page!4!)

!!

ATTACHING SCARAB TO DRIVER

Do not attempt to attach the Scarab with your variable speed grinder/

polisher plugged in.)

!

!

Refer to Exploded View of Scarab on page 15, Parts List on page 16.

•Milwaukee™ 5540 Polisher

•DeWalt ™ DWP849

•Metabo™ PE 12–175

•Flex™ LK603VVB

•Alpha™

Always refer to the variable speed grinder/polisher manual.

1. Choose the adapter ring that corresponds to your variable speed

grinder/polisher.

D-Dewalt™ F-Flex™ E-Metabo™ Milwaukee™

(#37) (#39) (#38) (#26)

!

!

!

!

!

2. Position the ring so that the outer lip is away from the grinder.

!

!

!

!

!

!

!

!

!

!

!

!

Compatible Variable Speed

Grinders/Polishers

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! )V%$+I+M)

!"#$%&!$'()*%+,%-))

Page!5!)

!!

!

3. Thread the appropriate arbor extension into the Scarab.

M–Metric (#36), I–Imperial (#23) or EXT will be stamped on the arbor.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

4. Thread the arbor of the variable speed grinder/polisher into the arbor

extension, leaving a very small gap between the two.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

5. Place the coupler halves (#7, #8) around the mounting rings. To fit all the

grooves into place you may need to adjust the gap between the arbor and

the arbor extension. Insert and tighten bolts (#12) to hold everything in place.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!"#$%&!$'()*%+,%-))

Page!6!)

!!

HANDLE ASSEMBLY INSTRUCTIONS

!

1. Choose the appropriate handle sides depending on the variable speed

grinder/polisher you are using.

Refer to Exploded View on page 15, Parts List on page 16.

DeWalt (#34) Standard (#33)

2. Using the M10 bolts provided (#12) fasten the longer (top) end to the handle

so that the handle narrows to the correct span for your variable speed

grinder/polisher.

!

!

!

!

!

!

!

!

!

!

!

!

3. Fasten the handle assembly to your variable speed grinder/polisher.

Note: Most variable speed grinder/polishers come with two (2) bolts to fasten

the handle assembly to the device.

DeWalt will require ½” bolts as the variable speed grinder/polisher

does not always come with an adjustable handle.

!

!

!

!

!

!

!

!

!

!

!

!

!"#$%&!$'()*%+,%-))

Page!7!)

!!

OPTIONAL HANDLE ASSEMBLY INSTRUCTIONS

!

1. Loosen bolts (#35). Reposition the handle assembly forward until horizontal.

Tighten bolts (#35). Loosen handle grip bolt (#12) and ensure the saddle bolt

hole is facing upwards. Tighten bolts (#12).

2. Insert saddle bolt through hole in handle grip (#32). Use the wing nut provided

to fasten the saddle (#41) in place.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

3. Connect the full extension articulating handle (#40) to the saddle, applying

light pressure to snap into place.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!"#$%&!$'()*%+,%-))

Page!8!)

!!

PRE-GRINDING/POLISHING INSTRUCTIONS

!

1. Choose surface type.

!

!

!

!!!!!Concrete Terrazzo Stone Wood Vinyl

2. Test the concrete surface using the MOHS Hardness Test Kit. For more

information visit the Learning Center at www.werkmaster.com.

3. Choose the pad driver and Plug ‘N Go tooling plate.

MODE

USE

Rigid

2 bumpers, 2 grommets

ULTRA-Flex

Remove bumpers, leave grommets

Medium Flex

Yellow compression foam

!

!

!

!

!!!!!!!!!!!!!!!!

!

!!!!!!!!!!!!!!!!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

4. Choose tooling. For a list of tooling options see the Tooling Selection Guide

under Products at www.werkmaster.com.

5. Become proficient with your Scarab. Practice on a test surface is

recommended.

!

!

!"#$%&!$'()*%+,%-))

Page!9!)

!!

MACHINE OPERATION

1. Always ensure the variable speed grinder/polisher is unplugged when

changing tooling or when not in use.

2. Set speed on low.

3. Securely grip the handle prior to turning variable speed grinder/polisher ON.

4. Squeeze trigger to start.

5. Release trigger prior to lifting off surface.

6. Unplug the machine and wait until the Plug ‘N Go tooling plates come to a

complete stop prior to making any adjustments.

NOTE:ALWAYS refer to the variable speed grinder/polisher manual.

CHANGING STANDARD TOOLING)

!

1. Standard Velcro™ tooling should be centered properly onto the Velcro™

plate.

2. To remove, simply pull Velcro™ apart.

3. Clean dust extraction and collection device/vacuum after every use.

!"#$%&!$'()*%+,%-))

Page!10!)

!

CHANGING PLUG ‘N GO TOOLING)

!

!

1. Firmly grasp Plug ‘N Go tooling. Attach tooling by aligning the two (2)

prongs into the Plug ‘N Go plate. Earth magnets will snap and secure tooling

in place. Ensure that each tooling piece is flush to the plate.

2. The tooling can be removed by hand, with a screwdriver or with pliers.

Protective gloves are recommended to protect from possible injury on small

metal shards.

3. Clean and store tooling in a dry compartment.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!"#$%&!$'()*%+,%-))

Page!11!)

!

ADJUSTING DUST SKIRT)

1. Adjust Velcro™ dust skirt (A) so that it is flush, or level, with the height of the

tooling. This helps direct dust particles to vacuum port, as well as protect

operator and surrounding objects from harm or damage from possible

projected objects.

2. The dust skirt comes in three (3) removable sections to allow the operator to

edge right to the wall.

3. As a safety measure, when removing a section of the dust skirt in order to

run the machine right to the wall keep the open section away from operator.

!

!

!

!

!

!

!

!

!

!

!

!

!

!!!!!!!!!!

!!!!

! !

!!!!!!!!

SETTING SPEED)

TOOLING

SPEED

Metal Bond

Low

Resins

Medium

Polishing

High

!

!

EDGING)

1. DO NOT run Scarab with Plug ‘N Go tooling right off the edge of counters as

the tooling segments might be ejected possibly causing harm of damage.

2. A video demonstration of the Scarab edging can be viewed at

www.werkmater.com Products/Machines/Scarab.

!

A!

!"#$%&!$'()*%+,%-))

Page!12!)

!

VACUUM

1. Use a 1 ½” hose reducer (not included) between the vacuum port (#9) to fit a

standard 2” vacuum hose.

2. Only run vacuum while dry grinding.

3. Always refer to vacuum manual.

!

WATER FEATURE PORT

!

!

!

Use extreme caution when working with electricity and water. Severe injury

or death may occur if caution is not used.

1. ALWAYS refer to the variable speed grinder/polisher manual prior to using

the water feature

2. Insert water feature plug into the vacuum port.

3. Ensure the blue flow control valve is in the OFF position.

4. Attach a ¾” male (standard garden hose) to the ¾” female end of the water

feature. To prevent leaks, secure tightly with a new washer.

5. Turn on water supply. Adjust the blue flow control valve as wet grinding

process requires.

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! )7%+M#$)

!"#$%&!$'()*%+,%-))

Page!13!)

!

CLEANING AND MAINTENANCE

The WerkMaster Scarab requires minimal maintenance.

1. Remove tooling after each use.

2. Vacuum and wipe clean of any built-up debris.

STORAGE

Store in a dry, non-corrosive environment.

!

!

TROUBLESHOOTING/TECH SUPPORT

!

A video demonstration of the Scarab can be viewed at www.werkmater.com

Products/Machines/Scarab.

Technical Support Form or phone 604.629.8700, toll free at 1.866.373.WERK.!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!"#$%&!$'()*%+,%-))

Page!14!)

!

OPTIONAL ACCESSORIES

) ) ) ) ) ) ) ))PART NO. ITEM

008-0273-00 Foam/Velcro Adapter Plate, 3”

008-0265-00 Plug ‘N Go Plate, 3”

002-0673-01 Plug ‘N Go Velcro Hook

008-0272-00 Plug ‘N Go Velcro Hook Replacement

008-0158-00 Foam Riser, 3” x 3/8”

008-0318-00 Compression foam, 3” X ¼”

010-0018-00 Water Feature

007-0006-00 MOHS Hardness Test Kit

!

!

!

!

!

010-0016-00 Full Extension Handle Assembly

!

!

!

!

!

!

!"#$%&!$'()*%+,%-))

Page!15!)

!

EXPANDED VIEW

!

!

!

!

!

!

!

!

)

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Other manuals for Scarab

1

Table of contents

Other WerkMaster Sander manuals