8

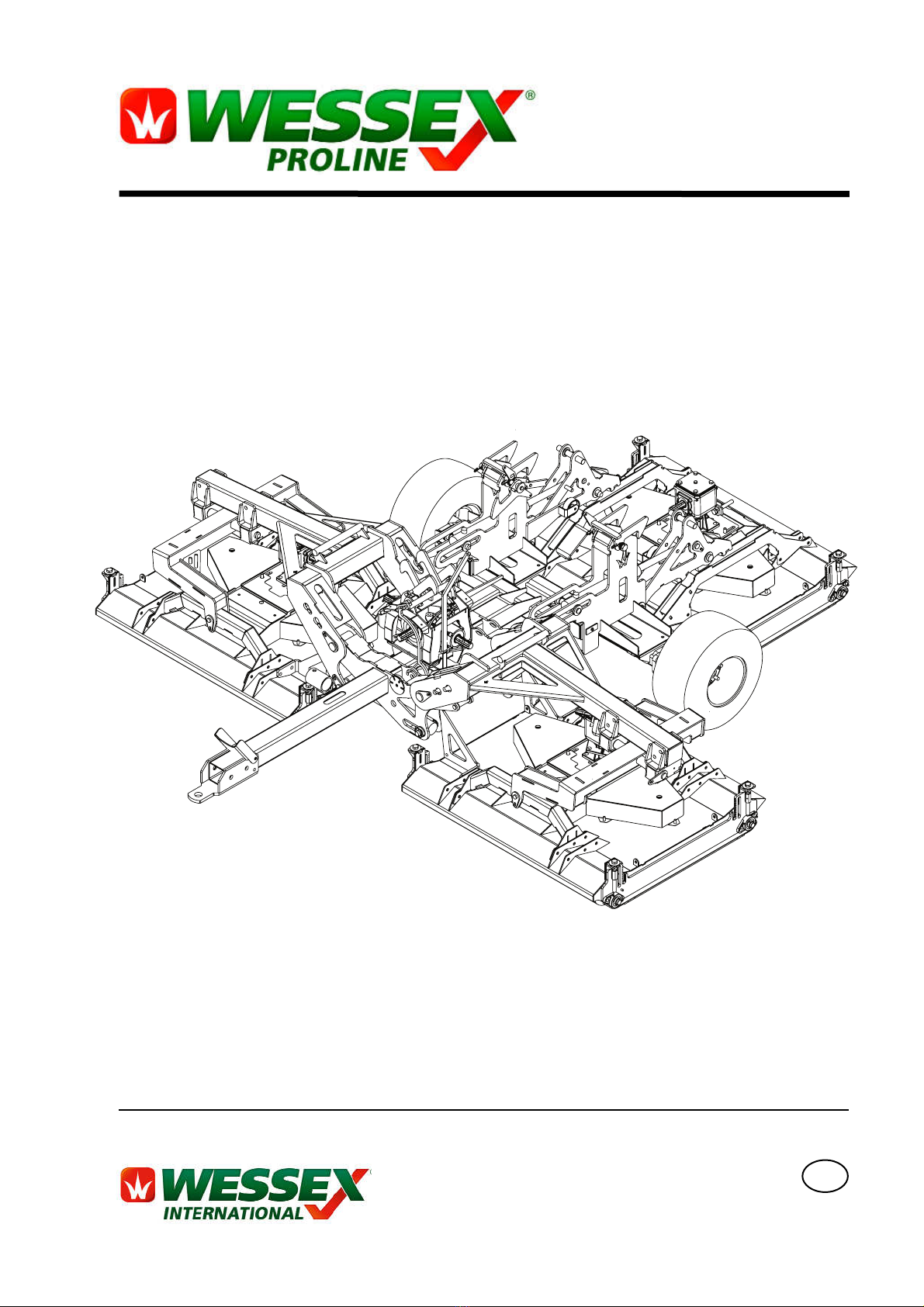

LINKING UP TO THE TRACTOR

1. Always hitch and unhitch on level ground for safety reasons.

2. When hitching up, never allow anyone to stand between the tractor and the implement.

3. Reverse the tractor up to the CRX Tri-deck and hitch up to the towing hitch. When using a

drawbar pin ensure that it is secured with a lynch pin.

4. When in work the drawbar of the CRX Tri-deck should be level with the ground, to adjust simply

remove drawbar holding bolts and turn the drawbar over for extra hight adjustment.

5. Stop the tractor’s engine and couple the P.T.O. shaft to the tractor putting the wide angle joint

onto the tractor. Always hook the P.T.O. chains onto the lugs provided and shorten the chains to

suit if required. The P.T.O. chains must not encircle the P.T.O. guard, as this will cause

premature P.T.O. guard damage and wear. Ensure that the P.T.O. Shaft is correctly located and

locked in place. (See P.T.O. shaft Instructions at the back of this manual).

6. If so equipped, connect the lighting plug into the tractor.

7. Connect the hydraulic hoses to the tractor. The CRX Tri Deck hydraulics are double acting and

of the two hoses provided, one should be connected to the flow port of the double acting tractor

spool and the other to the return port.

8. IMPORTANT:Ensure that the bottom link arms of the tractor do not come into contact the the

P.T.O. Shaft when turning. We recommend that you remove or raise up the tractor link arms by

adjustment of the arms.

9. For drawbar use the CRX Tri-deck can be equipped with a screw jack. To avoid damage to the

jack, remove and stow before moving or operating the mowing decks.

USING THE CRX TRI-DECK

1. Having hitched up to the tractor you are now ready to lower the mowing decks to the ground.

2. Important Ensure that all bystanders are at a safe distance from the machine and that the

machine is located on level ground before lowering the decks.

3. Operate the hydraulic spool function to take the weight off the safety catches of the side and

rear deck carriers.

4. Release the safety catches by activating the catch lever beside the drawbar at the front of the

machine, then slowly activate the hydraulic spool to lower the decks to the ground. Continue

to actuate the spool lever in lowering position for three seconds after the decks contact the

ground to ensure that the lift rams are fully extended. This will allow the cutting decks to follow

the ground contours fully. While mowing, the spool level should then be placed in the neutral

position.

5. When safe to do so, slowly engage the P.T.O. drive and select the forward speed carefully.

Start off slowly until you are confident with the working width and capability of the machine.

6. NEVER USE THE MOWER WITH P.T.O. SPEEDS IN EXCESS OF 540 RPM.

7. When mowing longer thicker grass a slower forward speed will need to be selected.

8. When mowing the CRX Tri-deck is capable of following very undulating ground conditions and

with care the side arms will happily run up or down banks of up to 30 degrees.

9. When lifting the mowing decks up and out of work STOP THE P.T.O. drive before lifting.

SERIOUS DRIVE LINE DAMAGE WILL RESULT IF THIS ADVICE IS IGNORED.