WEST PQP-171-P Guide

Technical Documentation

PQP-171-P

Universal pump control module

Page 2 of 34 PQP-171-P 05.06.2020

CONTENTS

1General Information.................................................................................................................................................4

1.1 Order number................................................................................................................................................. 4

1.2 Scope of supply.............................................................................................................................................. 4

1.3 Accessories.................................................................................................................................................... 4

1.4 Symbols used................................................................................................................................................. 5

1.5 Legal notice.................................................................................................................................................... 5

1.6 Safety instructions.......................................................................................................................................... 6

2Characteristics.........................................................................................................................................................7

2.1 Device description.......................................................................................................................................... 8

3Use and application.................................................................................................................................................9

3.1 Installation instructions ................................................................................................................................... 9

3.2 Typical system structure............................................................................................................................... 10

3.3 Method of operation...................................................................................................................................... 10

3.4 Commissioning............................................................................................................................................. 12

4Technical description.............................................................................................................................................13

4.1 Input and output signals ............................................................................................................................... 13

4.2 LED definitions ............................................................................................................................................. 13

4.3 Circuit diagram ............................................................................................................................................. 14

4.4 Typical wiring................................................................................................................................................ 15

4.5 Connection examples................................................................................................................................... 15

4.6 Technical data.............................................................................................................................................. 16

5Parameters............................................................................................................................................................17

5.1 Parameter overview...................................................................................................................................... 17

5.2 Basic parameters.......................................................................................................................................... 19

5.2.1 LG (Changing the language).................................................................................................................19

5.2.2 MODE (Parameter view).......................................................................................................................19

5.2.3 FIXCURR (Fix output value).................................................................................................................19

5.2.4 CTRLMODE (Control function) .............................................................................................................19

5.2.5 CCMODE (Characteristics linearization)...............................................................................................20

5.2.6 SENS (Malfunction monitor) .................................................................................................................20

5.2.7 EOUT (Output signal if not ready).........................................................................................................20

5.3 InSignal adaptation....................................................................................................................................... 21

5.3.1 SIGNAL (Type of input signal)..............................................................................................................21

5.3.2 N_RANGE:X (Sensor nominal pressure)..............................................................................................21

5.3.3 OFFSET:X (Sensor offset)....................................................................................................................21

5.3.4 RA (Command signal ramp time)..........................................................................................................22

5.3.5 CC (Characteristics linearization) .........................................................................................................23

5.4 Control parameters....................................................................................................................................... 24

5.4.1 PID controller........................................................................................................................................24

5.4.2 Integrator control function.....................................................................................................................25

5.4.3 C_EXT (Extended control parameters).................................................................................................25

5.5 Output signal adaptation............................................................................................................................... 26

5.5.1 MIN (Deadband compensation)............................................................................................................26

5.5.2 MAX (Output scaling)............................................................................................................................26

5.5.3 TRIGGER (Response threshold for the MIN parameter) ......................................................................26

5.5.4 SIGNAL:U (Output polarity) ..................................................................................................................27

5.6 Power stage.................................................................................................................................................. 28

5.6.1 CURRENT (Rated solenoid current).....................................................................................................28

5.6.2 DFREQ (Dither frequency)....................................................................................................................28

5.6.3 DAMPL (Dither amplitude)....................................................................................................................28

Page 3 of 34 PQP-171-P 05.06.2020

5.6.4 PWM (PWM Frequency)...................................................................................................................... 29

5.6.5 ACC (Current loop auto adjustment).................................................................................................... 29

5.6.6 PPWM (P gain of the current loop) ...................................................................................................... 29

5.6.7 IPWM (I gain of the current loop)......................................................................................................... 29

5.7 Special commands ....................................................................................................................................... 30

5.7.1 AINMODE (Scaling mode)................................................................................................................... 30

5.7.2 AIN (Analogue input scaling)................................................................................................................ 30

5.8 PROCESS DATA (Monitoring)...................................................................................................................... 31

6Appendix............................................................................................................................................................... 32

6.1 Failure monitoring......................................................................................................................................... 32

6.2 Troubleshooting............................................................................................................................................ 32

7Notes.................................................................................................................................................................... 34

Page 4 of 34 PQP-171-P 05.06.2020

1 General Information

1.1 Order number

PQP-171-P - pump control module with integrated power output stage up to 2,6 A and analouge

sensor interface

1.2 Scope of supply

The scope of supply includes the module plus the terminal blocks which are part of the housing.

The Profibus plug, interface cables and further parts which may be required should be ordered separately.

This documentation can be downloaded as a PDF file from www.w-e-st.de.

1.3 Accessories

WPC-300 - Start-Up-Tool (downloadable from our homepage –products/software)

Any standard cable with USB-A and USB-B connector can be used as the programming cable.

Page 5 of 34 PQP-171-P 05.06.2020

1.4 Symbols used

General information

Safety-related information

1.5 Legal notice

W.E.St.

Elektronik GmbH

Gewerbering 31

D-41372 Niederkrüchten

Tel.: +49 (0)2163 577355-0

Fax.: +49 (0)2163 577355-11

Home page: www.w-e-st.de

EMAIL: contact@w-e-st.de

Date: 05.06.2020

The data and characteristics described herein serve only to describe the product. The user is required to

evaluate this data and to check suitability for the particular application. General suitability cannot be inferred

from this document. We reserve the right to make technical modifications due to further development of the

product described in this manual. The technical information and dimensions are non-binding. No claims may

be made based on them.

This document is copyright.

Page 6 of 34 PQP-171-P 05.06.2020

1.6 Safety instructions

Please read this document and the safety instructions carefully. This document will help to define the product

area of application and to put it into operation. Additional documents (WPC-300 for the start-up software) and

knowledge of the application should be taken into account or be available.

General regulations and laws (depending on the country: e. g. accident prevention and environmental

protection) must be complied with.

These modules are designed for hydraulic applications in open or closed-loop control circuits.

Uncontrolled movements can be caused by device defects (in the hydraulic module or the

components), application errors and electrical faults. Work on the drive or the electronics must

only be carried out whilst the equipment is switched off and not under pressure.

This handbook describes the functions and the electrical connections for this electronic

assembly. All technical documents which pertain to the system must be complied with when

commissioning.

This device may only be connected and put into operation by trained specialist staff. The

instruction manual must be read with care. The installation instructions and the commissioning

instructions must be followed. Guarantee and liability claims are invalid if the instructions are

not complied with and/or in case of incorrect installation or inappropriate use.

CAUTION!

All electronic modules are manufactured to a high quality. Malfunctions due to the failure of

components cannot, however, be excluded. Despite extensive testing the same also applies

for the software. If these devices are deployed in safety-relevant applications, suitable external

measures must be taken to guarantee the necessary safety. The same applies for faults which

affect safety. No liability can be assumed for possible damage.

Further instructions

The module may only be operated in compliance with the national EMC regulations. It is

the user’s responsibility to adhere to these regulations.

The device is only intended for use in the commercial sector.

When not in use the module must be protected from the effects of the weather,

contamination and mechanical damage.

The module may not be used in an explosive environment.

To ensure adequate cooling the ventilation slots must not be covered.

The device must be disposed of in accordance with national statutory provisions.

Page 7 of 34 PQP-171-P 05.06.2020

2 Characteristics

This module is used as universal closed loop control module, e.g. for displacement swivel angel control. It has

an integrated power amplifier for proportional valves. Several setting parameters offer optimal adaption to the

valve. The controller runs with a loop time of 1 ms and the amplifier with 0,125 ms for the current control.

The command value and the feedback value are driven by scalable analogue signals (range 0… 10V or 4…

20mA). Ramp function and PID controller can be used universal. The output current is closed loop controlled

and therefore independent from the supply voltage and a varying solenoid resistance. The output stage is ca-

ble broken monitored and switches off in case of detected error.

Programmable are the following control parameters: SC, P, I, D, T1 and LIM for the integrator limitation as well

as different static settings and valve adjustments for the power stage like MIN, MAX, DITHER (in frequency

and amplitude) and the PWM frequency.

By the free parameterization of the power stage all typical proportional valves of the different manufactures

can be optimal adapted.

Because of the easy handling a very short training period is guaranteed.

Typical applications: General pressure control with pressure valves (direct or via a servo pump).

Features

Universal pump control module for proportional directional valves

Compact housing

Digital reproducible adjustments

Free scaling of the analogue input signals

Universal PID controller

Free parameterization of ramps, MIN and MAX, DITHER (frequency and amplitude) and

PWM frequency

Output current up to 2,6 A

Adaptable to all standard proportional valves

Application orientated parameter settings

Fault diagnosis and extended function checking

Simplified parameterization with WPC-300 software

Page 8 of 34 PQP-171-P 05.06.2020

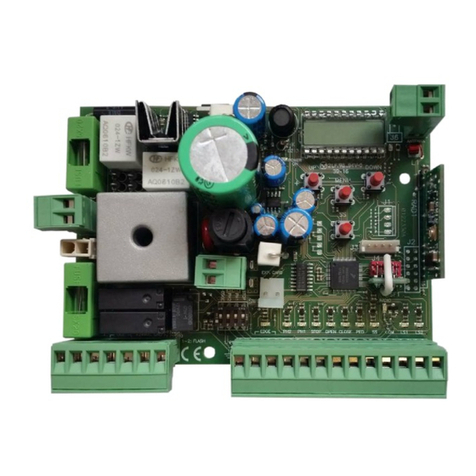

2.1 Device description

V:

ID:

Add.:Date:

Made in Germany

W.E.ST.

Ready

1 2 3 4

5 6 7 8

910 11 12

14 15 1613

D-41372 Niederkrüchten

Homepage: http://www.w-e-st.de

W.E.ST.

Elektronik

13 14 15

910 11 12

16

A B

Klemmblöcke (steckbar)

Terminals (removable)

LEDs

USB

Interface

Typenschild undAnschlussbelegung

Type plate and terminal pinassignment

23,0000 mm99,0000 mm

114,0000 mm

Page 9 of 34 PQP-171-P 05.06.2020

3 Use and application

3.1 Installation instructions

This module is designed for installation in a shielded EMC housing (control cabinet). All cables which

lead outside must be screened; complete screening is required. It is also necessary to avoid strong

electro-magnetic interference sources being installed nearby when using our open and closed loop

control modules.

Typical installation location: 24 V control signal area (close to PLC)

The devices must be arranged in the control cabinet so that the power section and the signal section

are separate from each other.

Experience shows that the installation place close to the PLC (24 V area) is most suitable. All digital

and analogue inputs and outputs are fitted with filters and surge absorbers in the device.

The module should be installed and wired in accordance with the documentation bearing in mind EMC

principles. If other consumers are operated with the same power supply, a star-shaped ground wiring

scheme is recommended. The following points must be observed when wiring:

The signal cables must be laid separately from power cables.

Analogue signal cables must be screened.

All other cables must be screened if there are powerful interference sources (frequency

converters, power contactors) and cable lengths > 3 m. Inexpensive SMD ferrites can be

used with high-frequency radiation.

The screening should be connected to PE (PE terminal) as close to the module as

possible. The local requirements for screening must be taken into account in all cases. The

screening should be connected to at both ends. Equipotential bonding must be provided

where there are differences between the connected electrical components.

If having longer lengths of cable (> 10 m), the diameters and screening measures should

be checked by specialists (e. g. for possible interference, noise sources and voltage drop).

Special care is required if using cables of over 40 m in length, and if necessary the

manufacturer should be consulted if necessary.

A low-resistance connection between PE and the mounting rail should be provided. Transient

interference is transmitted from the module directly to the mounting rail and from there to the local

earth.

Power should be supplied by a regulated power supply unit (typically a PELV system complying with

IEC364-4-4, secure low voltage). The low internal resistance of regulated power supplies gives better

interference voltage dissipation, which improves the signal quality of high-resolution sensors in

particular. Switched inductances (relays and valve coils) which are connected to the same power

supply must always be provided with appropriate overvoltage protection directly at the coil.

Page 10 of 34 PQP-171-P 05.06.2020

3.2 Typical system structure

This minimal system consists of the following components:

(*1) Swivel angel adjustment

(*2) Servo pump

(*3) Swivel angel sensor

(*4) Pump controller PQP-171-P

(*5) Interface to PLC

3.3 Method of operation

This swivel angel controller is driven via an analogue signal. The ENABLE signal (typical 24 V) activates the

functionality and reports this at a READY output if no error occurs.

In case of malfunction the power stage gets deactivated and the error is reported by a deactivated READY

output and a flashing READY LED.

The output is current controlled whereby a high accuracy and a good dynamic is obtained.

In this system the speed of the cylinder is adjusted by the swivel angel of the pump. Because of the relatively

pressure independent volume flow compared to a throttle control with a proportional valve the actuator can be

driven by relative continual speed.

The system is realized by an electro-hydraulic control equipment controlled by our module. As feedback the

swivel angel is measured and send back to the module.

Via a modified and optimized PID controller the behavior can be adapted to the respective pump.

The valve controlling can be switched between such with one solenoid and also two solenoids (shown on pic-

tures 1 and 2).

Page 12 of 34 PQP-171-P 05.06.2020

3.4 Commissioning

Step

Task

Installation

Install the device in accordance with the circuit diagram. Ensure it is wired cor-

rectly and that the signals are well shielded. The device must be installed in a

protective housing (control cabinet or similar).

Switching on for the first time

Ensure that no unwanted movement is possible in the drive (e. g. switch off the

hydraulics). Connect an ammeter and check the current consumed by the de-

vice. If it is higher than specified, there is an error in the wiring. Switch the de-

vice off immediately and check the wiring.

Setting up communication

Once the power input is correct the PC (notebook) should be connected to the

serial interface. Please see the WPC-300 program documentation for how to

set up communication.

The operating software supports further commissioning and diagnosis.

Pre-parameterization

Parameterize now (with the help of the system redundancy and the connection

diagram) the following parameters:

The NOMINAL PRESSURE for the ANALOGUE INPUTS. See specifications of

the system and the sensors.

The output CURRENT and the typical valve parameter DITHER and MIN/MAX.

Pre-parameterization is necessary to minimize the risk of an unintentional

movement / pressure.

Control signal

Check the control signal (output signal). The control signal (solenoid current)

lies in the range of 0... 2,6 A. In the current state it should show around 0 A.

CAUTION! This signal depends on the EOUT setting.

Switching on the hydraulics

The hydraulics can now be switched on. The module is not yet generating a

signal. Drives should be at a standstill or drift slightly (leave its position at a

slow speed).

Activating ENABLE

CAUTION! The power stage gets activated.

The controller can now be driven by the analogue command value. The feed-

back value is read in and the output signal gets calculated by means of the

control deviation and the parameterization.

Controller optimization

Now optimize the settings. The PID parameters have to be adapted depending

on the application.

Page 13 of 34 PQP-171-P 05.06.2020

4 Technical description

4.1 Input and output signals

4.2 LED definitions

LEDs

Description of the LED function

GREEN

Identical to the READY output.

OFF: No power supply or ENABLE is not activated

ON: System is ready for operation

Flashing: Error discovered

YELLOW A

Intensity of the current at solenoid A

YELLOW B

Intensity of the current at solenoid B

GREEN +

YELLOW A

1. Chasing light (over all LEDs): The bootloader is active. No normal functions are

possible.

2. All LEDs flash shortly every 6 s: An internal data error was detected and corrected

automatically! The module still works regularly. To acknowledge the error the module

has to be cycle powered.

YELLOW A +

YELLOW B

Both yellow LEDs flash oppositely every 1 s: The nonvolatile stored parameters are in-

consistent! To acknowledge the error, data has to be saved with the SAVE command or

the corresponding button in the WPC.

Connection

Supply

PIN 7

Power supply (see technical data)

PIN 8

0 V (GND) connection.

Connection

Analogue signals

PIN 9 / 10

Command value (WA), signal range 0… 10 V or 4… 20 mA, scalable

PIN 13 /14

Feedback value (X), signal range 0… 10 V or 4… 20 mA, scalable

PIN 11

0 V (GND) connection for analogue signals

PIN 12

8V reference voltage output

Connection

Solenoids

PIN 2 / 1

PWM output solenoid B

PIN 3 / 4

PWM output solenoid A

Connection

Digital inputs and outputs

PIN 15

ENABLE input:

Generally enabling of the application. Activates controller, power stage and READY.

PIN 6

FIXCURRENT input:

ON: Direct control of the power stage via the FIXCURR parameter.

OFF: Swivel angel control is active (normal state).

PIN 5

READY output:

ON: The module is enabled; there are no discernable errors.

OFF: ENABLE is not available or an error has been detected.

Page 14 of 34 PQP-171-P 05.06.2020

4.3 Circuit diagram

2

Input

PE via DIN-RAIL

3

4

1

5

15

Ready

Enable

Fixcurr

Digital Output

USB type B

PQP-171-P

6

13

Valve

adaption

Digital Input

u

Control program

Ramp

function PID

control

function

ia

ib

to solenoidA

c

wa

x

12

GND

+Ub

8

7

DC

DC

to solenoid B

Power

supply

Power

stage

Digital Input

Reference

voltage

14

11

Setpoint

Actual

value

Scaling

Input

Scaling

9

10

Differetial Input

we

+

-

Page 15 of 34 PQP-171-P 05.06.2020

4.4 Typical wiring

Enable

8765

16151413

1211109

Analogue command signal

Solenoid

4321

0V

Shield

PE

Power Supply

0V

12 V / 24 V

+

-

Feedback signal

+

Reference voltage output

Ready

A

Solenoid B

FC

Digital input

output

PE

0V

0V

4.5 Connection examples

8V PIN 12

GND PIN 11

+In PIN 9

-In PIN 10

Potentiometer / Joystick

+In PIN 9

-In PIN 10

SPS / PLC 0... 10 V/ +/- 10 V

8V PIN 12

GND PIN 11

+In PIN 9

-In PIN 10

Joystick

4... 20 mA input

+In PIN 9 + 13

-In PIN 10 + 14

GND PIN 11

Alternative 3 –wire connection of two solenoids:

Example.: Hawe valves

3

4

1

2

A-Solenoid

B-Solenoid

Page 16 of 34 PQP-171-P 05.06.2020

4.6 Technical data

Supply voltage (Ub)

Current requirement

External protection

[VDC]

[mA]

[A]

12… 30 (incl. ripple)

30 + solenoid current

3 medium time lag

Reference output

Voltage

Max. load

[V]

[mA]

8

25

Digital inputs

OFF

ON

Input resistance

[V]

[V]

[kOhm]

< 2

> 10

25

Digital outputs

OFF

ON

Max. output current

[V]

[V]

[mA]

< 2

max. Vcc

50

Analog inputs:

Voltage

Input resistance

Current

Burden

Signal resolution

[V]

[kOhm]

[mA]

[Ohm]

[%]

Unipolar / differential

0… 10 / -10… 10

min. 90

4… 20

390

0,03

PWM output

Max. output current

Frequency

[A]

[Hz]

Wire break and short circuit monitored

2,6

61… 2604 selectable in defined steps

Controller cycle times

Solenoid current control

Signal processing

[µs]

[ms]

125

1

Serial interface

Transmission rate

-

[kBaud]

USB - virtual COM Port

9,6… 115,2

Housing

Material

Flammability class

Snap-on module acc. EN 50022

PA 6.6 polyamide

V0 (UL94)

Weight

[kg]

0,13

Protection class

Temperature range

Storage temperature

Humidity

Vibration resistance

[IP]

[°C]

[°C]

[%]

-

20

-20… 60

-20… 70

< 95 (non-condensing)

IEC 60068-2-6 (Category C)

Connections

Communication

Plug connectors

PE

-

USB type B

4 x 4-pole terminal blocks

via the DIN mounting rail

EMC

EN 61000-6-2: 8/2005

EN 61000-6-4: 6/2007 + A1:2011

Page 17 of 34 PQP-171-P 05.06.2020

5 Parameters

5.1 Parameter overview

Group

Command

Default

Unit

Description

Basic parameters

LG

EN

-

Changing language help texts

MODE

STD

-

Parameter view

FIXCURR

Fix output value for corresponding digital input

CTRLMODE

OL

-

Closed loop (CL) or open loop (OL) control.

CCMODE

OFF

-

Activation / deactivation of the CC function.

SENS

ON

-

Malfunction monitor

EOUT

0

0.01 %

Output signal if not ready

Input signal adaptation

Sensor scaling

SIGNAL:X

U0-10

V

Type of input

N_RANGE:X

100

%

Sensor working range in relation to system working range

OFFSET:X

0

0.01 %

Sensor offset

Command signal scaling

SIGNAL:W

U0-10

mbar

Type of input

Ramp function

RA:UP

RA:DOWN

100

100

ms

ms

Command signal ramp times

Characteristic linearization

CC

X Y

0,01 %

X Y parameter for up to 10 points.

Control parameters

PID controller

C:P

C:I

C:D

C:D_T1

C:OFFSET

100

4000

0

500

0

0.01

0.1 ms

0.1 ms

0.1 ms

0.01 %

P gain

I gain

D gain

D gain filter

Direct control

Integrator control

C:I_LIM

2500

0.01 %

Integrator limitation

Extended control parameter

C_EXT:P

C_EXT:T1

C_EXT_FF

0

200

0

0.01

0.1 ms

0.01 %

P gain

P gain filter

Feed forward

Output signal adaptation

MIN:A

MIN:B

0

0

0.01 %

0.01 %

Deadband compensation

MAX:A

MAX:B

10000

10000

0.01 %

0.01 %

Output scaling

TRIGGER

200

0.01 %

Deadband compensation trigger point

SIGNAL:U

1S+

-

Type and polarity of the output

Page 18 of 34 PQP-171-P 05.06.2020

Group

Command

Default

Unit

Description

Parameters of the power stage

CURRENT

1000

mA

Rated solenoid current

DFREQ

121

Hz

Dither frequency

DAMPL

500

0.01 %

Dither amplitude

PWM

2604

Hz

PWM frequency

ACC

ON

-

Current loop auto adjustment

PPWM

IPWM

7

40

-

-

P-Gain of the current loop

I-Gain of the current loop

Special commands

Scaling mode

AINMODE

EASY

-

Input scaling mode

AIN:X

AIN:W

A: 1000

B: 1000

C: 0

X: V

-

-

0.01 %

-

Free scaling of the analogue inputs. Gets activated when

AINMODE is switched over to MATH.

Page 19 of 34 PQP-171-P 05.06.2020

5.2 Basic parameters

5.2.1 LG (Changing the language)

Command

Parameters

Unit

Group

LG x

x= DE|EN

-

STD

Either German or English can be selected for the help texts.

CAUTION: After changing the language settings, the ID button in the menu bar (WPC-300) must be

pressed (module identification).

5.2.2 MODE (Parameter view)

Command

Parameters

Unit

Group

MODE x

x= STD|EXP

-

STD

This command changes the operating mode. Various commands (defined via STD/EXP) are blanked out in

Standard Mode. The commands in Expert Mode have a more significant influence on system behavior and

should accordingly be changed with care.

5.2.3 FIXCURR (Fix output value)

Command

Parameters

Unit

Group

FIXCURR x

x= -10000… 10000

0.01 %

STD

This command changes the operating mode. Various commands (defined via STD/EXP) are blanked out in

Standard Mode. The commands in Expert Mode have a more significant influence on system behavior and

should accordingly be changed with care.

5.2.4 CTRLMODE (Control function)

Command

Parameters

Unit

Group

CTRL x

x= OL|CL

-

STD

Switching the control function between OL (open loop) for direct control of the solenoid current and

CL (closed loop) for using extended PID controller with feedback sensor.

Page 20 of 34 PQP-171-P 05.06.2020

5.2.5 CCMODE (Characteristics linearization)

Command

Parameter

Unit

Group

CCMODE X

x= ON|OFF

-

EXP

This command activates the characteristic linearization function. Deactivating immediately allows an easy and

fast evaluation of the linearization.

5.2.6 SENS (Malfunction monitor)

Command

Parameters

Unit

Group

SENS x

x= ON|OFF|AUTO

-

STD

This command is used to activate/deactivate the monitoring functions (4… 20 mA sensors, output current, sig-

nal range and internal failures) of the module.

ON: All monitoring functions are active. Detected failures can be reset by deactivating the ENABLE in-

put.

OFF: No monitoring function is active.

AUTO: Auto reset mode. All monitoring functions are active. If the failure doesn’t exist anymore, the mod-

ule automatically resumes to work.

Normally the monitoring functions are always active because otherwise no errors are detectable via

the READY output. Deactivating is possible mainly for troubleshooting.

5.2.7 EOUT (Output signal if not ready)

Command

Parameters

Unit

Group

EOUT X

x= -10000… 10000

0.01 %

EXP

Output value in case of a detected error or a deactive ENABLE input. A value (degree of valve opening) for

use in the event of a sensor error (or the module is disabled) can be defined here. This function can be used if,

for example, the drive is to move to one of the two end positions (at the specified speed) in case of a sensor

error.

|EOUT| = 0 The output is switched off in the event of an error. This is normal behavior.

CAUTION!

The output value defined here is stored permanently (independently of the parameter set). The

effects should be analyzed by the user for each application from the point of view of safety.

Table of contents

Popular Control Unit manuals by other brands

RIB

RIB R10-CRX manual

Woodhead

Woodhead applicom PCI4000 manual

Omron

Omron CS1W-NC113 - REV 02-2008 datasheet

Kidde Fire Systems

Kidde Fire Systems ARIES NETLink 76-800300-007 installation instructions

Emerson

Emerson KTM Hindle Operation, installation & maintenance instructions

Notifier

Notifier LDM-32 Installation sheet