NIPPON VALVE CONTROLS Vpro MAX Series User manual

OSYBR23B-EN

1/9

NIPPON VALVE CONTROLS, INC.

Instruction manual

MA

X

SERIES

B

all

Valve

BR

B

S

V

R

T

R

L

R

T

3

L

3

SP-1519

Please read this manual before installation and use.

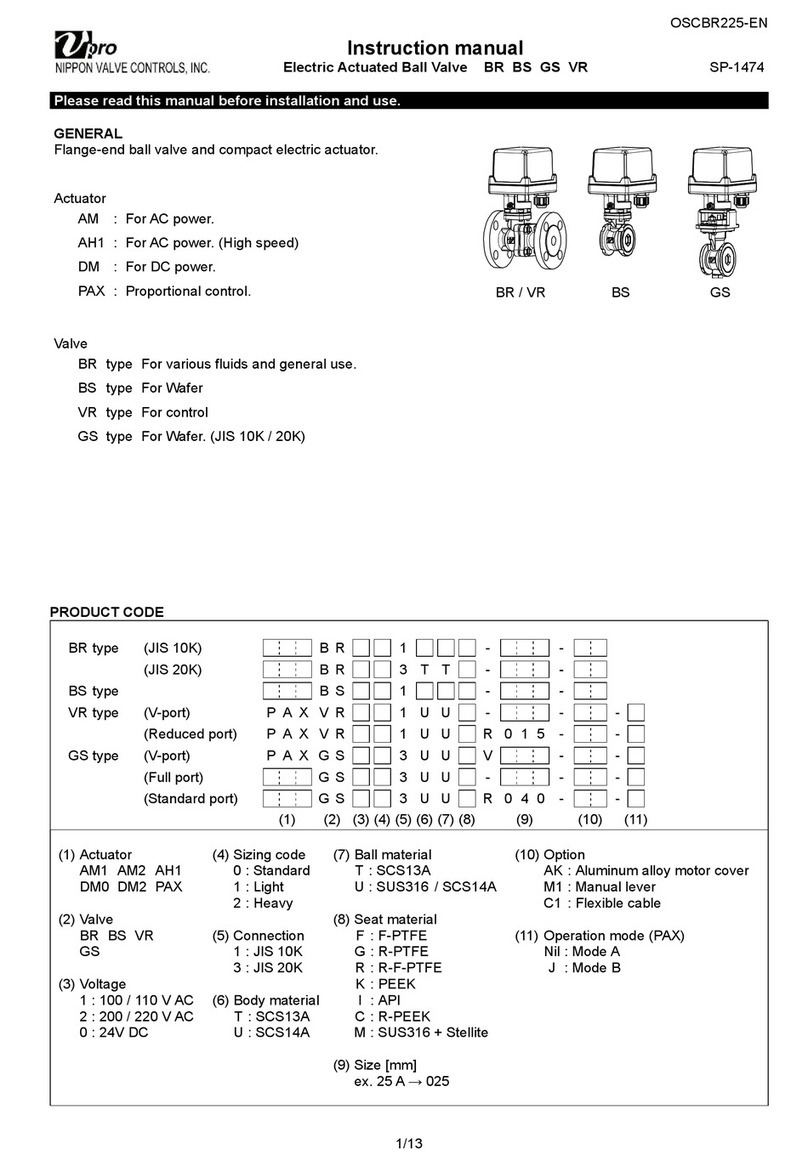

GENERAL

This series is suitable for main or bypass valve in piping system.

The position of manual handle can be changed.

Manual operation

Valve only

Lever

Gear

Valve

BR type For various fluids and general use.

BS type For Wafer.

VR type For control.

TR type For mixing / dividing.

LR type For mixing / dividing.

T3 type Trunnion structure. (with flow paths)

L3 type Trunnion structure.

PRODUCT CODE

BR type M A X B R - - -

BS type (Full port) M A X B S - 1 - -

(Standard port) M A X B S - 1 R -

VR type M A X V R - 1 U U - -

(Standard port) M A X V R - 1 U U R 0 1 5 -

TR type M A X T R - 1 T T P - -

LR type M A X L R - 1 T T P - -

T3 type M A X T 3 - 1 T T G - - -

L3 type M A X L 3 - 1 T T G - -

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

(1) Actuator

MAX

(2)

Valve

BR BS

V

R

TR LR

T3 L3

(3) Operation

0 : (Zero) Valve only

L : With manual lever

G : Gear

(4) Hyphen

(5) Connection

1 : JIS 10K

3 : JIS 20K

(6) Body material

T : SCS13A

U : SCS14A

(7) Ball material

T : SUS304 / SCS13A

U : SUS316 / SCS14A

(8) Seat material

F : F-PTFE

G : R-PTFE

R : R-F-PTFE

P : R-PTFE

(9) Size [mm]

ex. 25 A ® 025

(10) Option

(11) Flow paths (T3)

a to d : 3 way valve flow

OSYBR23B-EN

2/9

VALVES SPECIFICATIONS

Water Oil Air, Gas Steam Chemicals Sea water Slurry Negative pressure

BR BS type

Valve type BR BS

Design 2-way, Full port 2-way, Wafer

Full port Standard port

Connection JIS10K Flanged-end JIS20K Flanged-end JIS Flanges 10K

Fluid

Max pressure 1 MPa 2 MPa 1 MPa

Size [mm] 015 to 100 015 to 150 015 to 080 015 to 80 R100 to R150

Material Body SCS14A SCS13A SCS13A SCS13A SCS14A SCS13A

Ball SCS14A SCS13A SCS13A SCS13A SCS14A SCS13A

Seat F-PTFE R-PTFE R-F-PTFE F-PTFE R-PTFE R-F-PTFE

Stem seal Packing R-PTFE R-PTFE

O-ring FKM FKM

The optional for steam fluids.

Valve type Option code O-ring

BR BS ST Replace (Steam resistant FKM)

PRESSURE & TEMPERATURE RATING

BR (JIS 10K) BR (JIS 20K) BS

Note) Insulation options are required for use with fluids more than 150 °C.

INHERENT FLOW CHARACTERISTIC (BS)

R100 to R150 mm

Cv value (%)

Valve opening (%)

Range ability 30:1

OSYBR23B-EN

3/9

VALVES SPECIFICATIONS

Water Oil Air, Gas Steam Chemicals Sea water Slurry Negative pressure

VR

type

Valve type VR

Design 2-way, V-port

Connection JIS10K Flanged-end

Fluid

Max pressure 1 MPa

Size [mm] R015 015 to 080

Material Body SCS14A

Ball SUS316 SCS14A

Seat R-PTFE R-F-PTFE

Stem seal Packing R-PTFE

O-ring FKM

The optional for steam fluids.

Valve type Option code O-ring

V

R ST Replace (Steam resistant FKM)

PRESSURE & TEMPERATURE RATING

Note) Insulation options are required for use with fluids more than 150 °C.

INHERENT FLOW CHARACTERISTIC

Cv value (%)

Valve opening (%)

Range ability

VR-1UUG R 015 100:1

VR-1UUG - 015 to 080 50:1

OSYBR23B-EN

4/9

VALVES SPECIFICATIONS

Water Oil Air, Gas Steam Chemicals Sea water Slurry Negative pressure

TR LR type

Valve type TR LR

Design 3-way, Full port

Connection JIS10K Flanged-end

Fluid

Max pressure 1 MPa

Size [mm] 020 to 040 050 to 100

Material Body SCS13A

Ball SUS304 SCS13A

Seat R-PTFE

Stem seal Packing R-PTFE

O-ring FKM

The optional for steam fluids.

Valve type Option code O-ring

TR LR ST Replace (Steam resistant FKM)

PRESSURE & TEMPERATURE RATING

Note) Insulation options are required for use with fluids more than 150 °C.

INHERENT FLOW CHARACTERISTIC

020 mm 025 mm 040 mm 050 to 100 mm

Cv value (%)

Cv value (%)

Cv value (%)

Cv value (%)

Valve opening (%)

Valve opening (%)

Valve opening (%)

Valve opening (%)

Range ability 20:1

FLOW PATHS (Position / P1) (Position / P2)

P1 P2

B-C A-C

Note) When a closed path is exposed to high pressure, it may leak slightly to an open path.

OSYBR23B-EN

5/9

VALVES SPECIFICATIONS

Water Oil Air, Gas Steam Chemicals Sea water Slurry Negative pressure

T3 L3 type

Valve type T3 L3

Design 3-way, Full port

Connection JIS10K Flanged-end

Fluid

Max pressure 1 MPa

Size [mm] 025 to 150

Material Body SCS13A

Ball SCS13A

Seat R-PTFE

Stem seal Packing PTFE

The optional for steam fluids.

Valve type Option code O-ring

T3 L3 ST-VF Add (Steam resistant FKM)

PRESSURE & TEMPERATURE RATING

T3 L3

Note) Insulation options are required for use with fluids more than 170 °C.

INHERENT FLOW CHARACTERISTIC (L3)

025 mm 040 to 150 mm

Cv value (%)

Cv value (%)

Valve opening (%)

Valve opening (%)

Range ability 30:1

FLOW PATHS (Position / P1) (Position / P2)

T3 L3

Code: a Code: b Code: c Code: d

P1 P2 P1 P2 P1 P2 P1 P2 P1 P2

A-B B-C A-C A-B B-C A-B-C A-B-C A-C B-C A-C

OSYBR23B-EN

6/9

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

MANUAL LEVER DIMENSIONS

CASTING LEVER

Valve size [mm] Lever [mm]

Hex bolt

BS

BR

VR

TR

LR

L3

T3 L H A

015

020

015

020 - 115 36 9

M5×15

025

032

025

032 025 145 46 11

040

050

040

050 040 220 52 14 M6×15

065

080

100

065

080

050

065 320 55 17 M8×15

125

150

100

125

080

100 430 60 22 M10×20

PIPE LEVER

Valve size [mm] Lever [mm]

Knob bolt

BR

L3 T3 L

150 125

150 750 M10×25

HANDLING OF MANUAL LEVER

Attention

• The lever handle is removed and shipped.

• The lever mounting direction can be changed in units

of 45 degrees.

• Do not apply excessive torque to the lever.

• Do not strike or extend the lever with a tool.

• The arrow on the plate indicates the direction of flow.

LEVER HANDLE INSTALLATION (Casting lever)

• Plate of position indicator is attached on the valve by

C-type snap ring. Install the manual lever on it

tightening the bolt.

• The position of manual lever can be changed

according to piping circumstances.

LEVER HANDLE INSTALLATION (Pipe lever)

• Remove the bolt and nut from the lever.

• Loosen the knob bolt. Insert the lever into the

connector.

• Tighten the bolts so that the lever does not fall off.

• Fix the lever with the knob bolt.

L

H

A

L

Knob bolt

Pipe lever

Bolt,

Nut

Connector

OSYBR23B-EN

7/9

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

GEAR DIMENSIONS

Valve size [mm]

K [mm] Actuator

BS

BR

VR

TR

LR

L3

T3

065

080

100

065

080

050

065 150 MAG-F07

125

150

100

125

080

100 300 MAG-F10

- 150 125

150 300 MAG-F12

HANDLING OF GEAR

• The handle wheel of the gear is removed and

shipped.

• Insert the handle into the gear shaft.

• Insert a pin into the hole in the handle.

φK

OPEN SHUT

Handle

Pin

OSYBR23B-EN

8/9

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

HANDLING & STORAGE

HANDLING

Do not drop or throw the product as it may break.

STORAGE

• Store away from dust, moisture and direct sunlight.

If possible, store in the original package.

• Do not remove a dust proof cap until the piping.

CHECKING

• Check the product code before installation.

• Make sure that the bolts are not loose.

INSTALLATION

PRECAUTIONS

• Flush the pipeline carefully before installing the valve.

Foreign particles, such as sand or pieces of welding

electrode, will damage the ball and seats.

• For valves with specified flow direction (VR) or with

ST / SC option, check the arrows on the product

before piping.

• When the flow path is subjected to a high pressure

from arrow, it may leak slightly to the low pressure

port. (TR, LR)

PIPING FLANGES

• Gasket should be selected appropriately to suit the

fluid, pressure and temperature.

Use spring washer to prevent from decreasing surface

pressure gasket when the temperature change

happens frequently.

• Tighten all bolts using crossover method to load the

joint evenly.

• Wafer type ball valve is put between two seats of

flanged-end and tightened with long bolts. (BS)

ENVIRONMENT

If there is a possibility that the fluid and drive part

freeze, please take measures to prevent freezing.

POSITIONING

Should be positioned through 90° upward from

horizontal. Provide space around the product to allow

manual operation, inspection and replacement work.

CAUTIONS FOR MAINTENANCE (T3, L3)

Do not keep warm for maintenance of the valve gland.

TIGHTEN THE GLAND NUTS (T3, L3)

• Check that there is no leakage from the gland

packing.

• If it leakage, tighten gland nuts by alternately.

Do not over-tighten the gland nuts.

Valve size [mm] T Recommended

torques [Nm]

T3 L3

025 025 3.5

040 040

050 7

050

065

065

080 10

080

100

100

125 14

125

150 150 20

MAINTENANCE

Do the routine maintenance at least once in half a

year.

Inspection items

• Confirm operation of opening and closing.

• Confirm whether screws are loose or not.

• Confirm the fluid temperature or pressure.

• Confirm the leak from valve stem.

• Confirm the bolt tightening torque.

Packing

Gland nut

OSYBR23B-EN

Document is subject to change without notice.

NIPPON VALVE CONTROLS, INC.

1-21-19 Meieki minami, Nakamura-ku, Nagoya 450-0003 JAPAN

TEL: 81-52-582-6435 FAX: 81-52-582-6439

9/9

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

TROUBLESHOOTING

Problem Cause Solution

Stop in the

mid position.

• Biting of

valve seat.

• The scale

has adhered

to the valve

ball.

Remove a foreign

object.

Leakage

from

valve body

• Valve cap get

loose.

• Valve body is

damaged.

Replace the valve.

Leakage

from

valve seat

Seat is worn

or damaged.

Replace the valve.

Replace the seat.

Leakage

from

valve stem

Stem packing is

worn or

distorted.

Replace the valve.

Replace the packing.

Leakage

from

valve gland

Gland packing

is worn or

distorted.

Tighten the gland nut.

T3 L3 Replace the gland

packing.

For more information contact

NIPPON VALVE CONTROLS, INC. for consultation.

This manual suits for next models

7

Table of contents

Other NIPPON VALVE CONTROLS Control Unit manuals

Popular Control Unit manuals by other brands

Truma

Truma iNet X operating instructions

REXROTH

REXROTH UPE 2 manual

Infinite

Infinite L-COM SRAQ-G014 user guide

Asco

Asco 8210 Series Installation & maintenance instructions

Automationdirect.com

Automationdirect.com Productivity 2000 P2-15TD2 manual

White Rodgers

White Rodgers 36C03 installation instructions

Montech

Montech MonTurn TB40 Assembly instructions

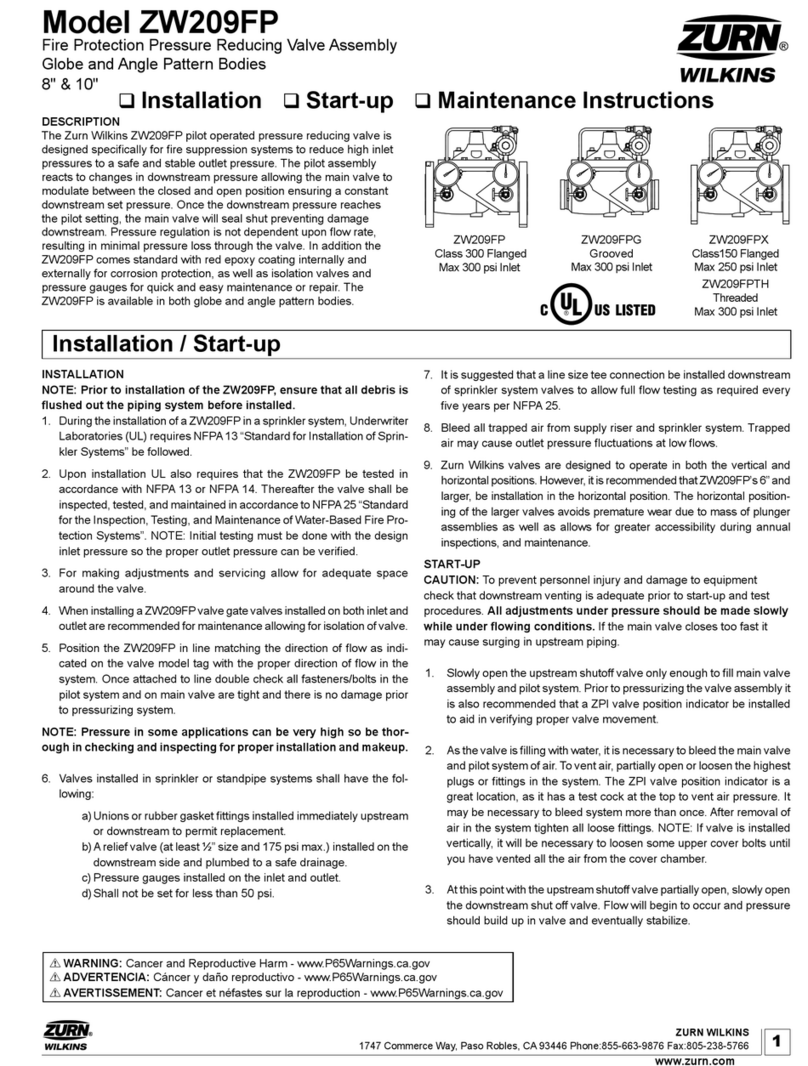

Zurn Wilkins

Zurn Wilkins ZW209FP Installation, Start-up, Maintenance Instructions

Quectel

Quectel BC66-NA manual

Hydro Instruments

Hydro Instruments PRV-71H Series Operation and maintenance manual

EVERSPRING

EVERSPRING AN196 quick start guide

Siemens

Siemens SIMATIC TDC System manual