Lit. No. 48163, Rev. 00 March 15, 2016

3

TABLE OF CONTENTS

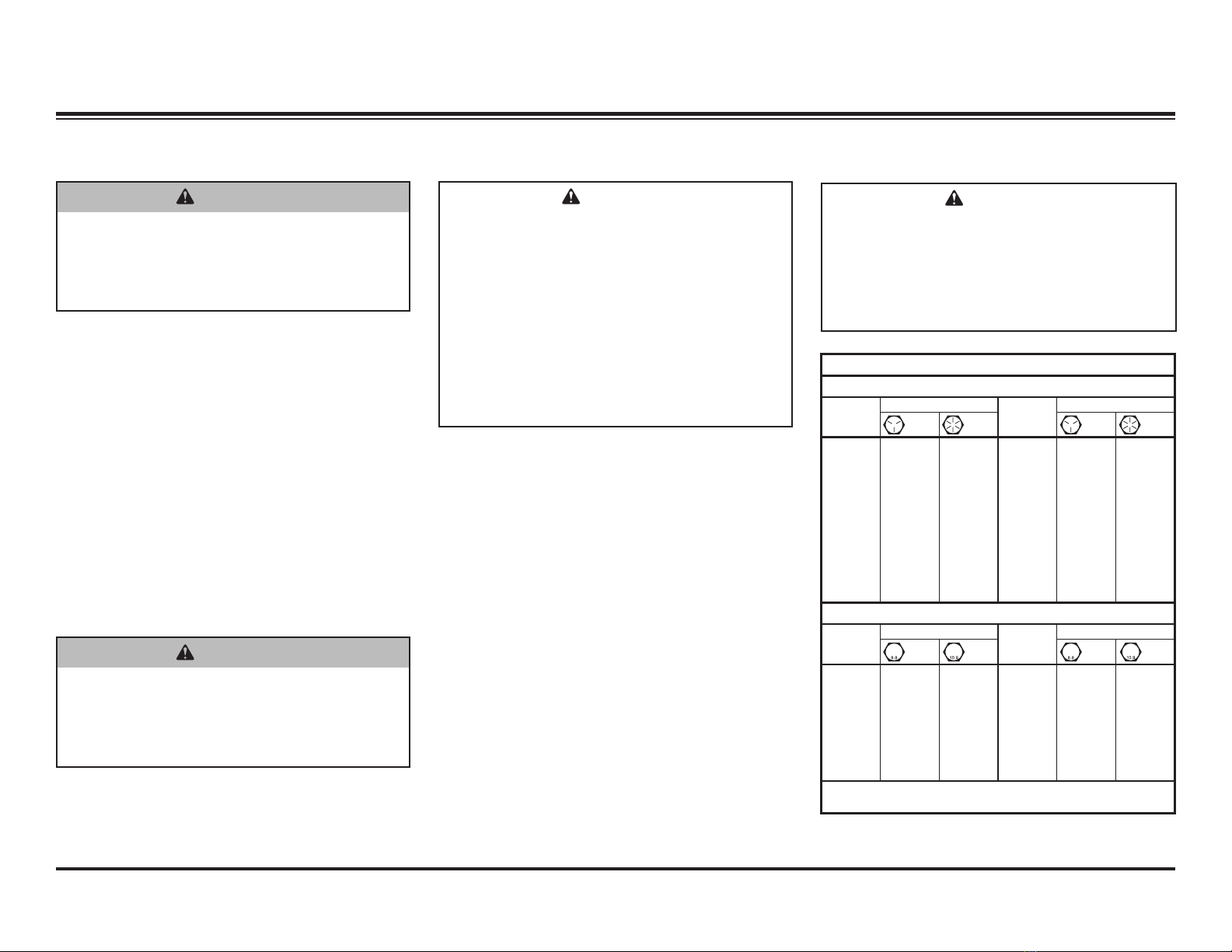

SAFETY INFORMATION.............................................................................. 5–7

Torque Chart ................................................................................................7

INTRODUCTION................................................................................................8

Recommended Tools...................................................................................8

WESTERN®Service Kits Available..............................................................8

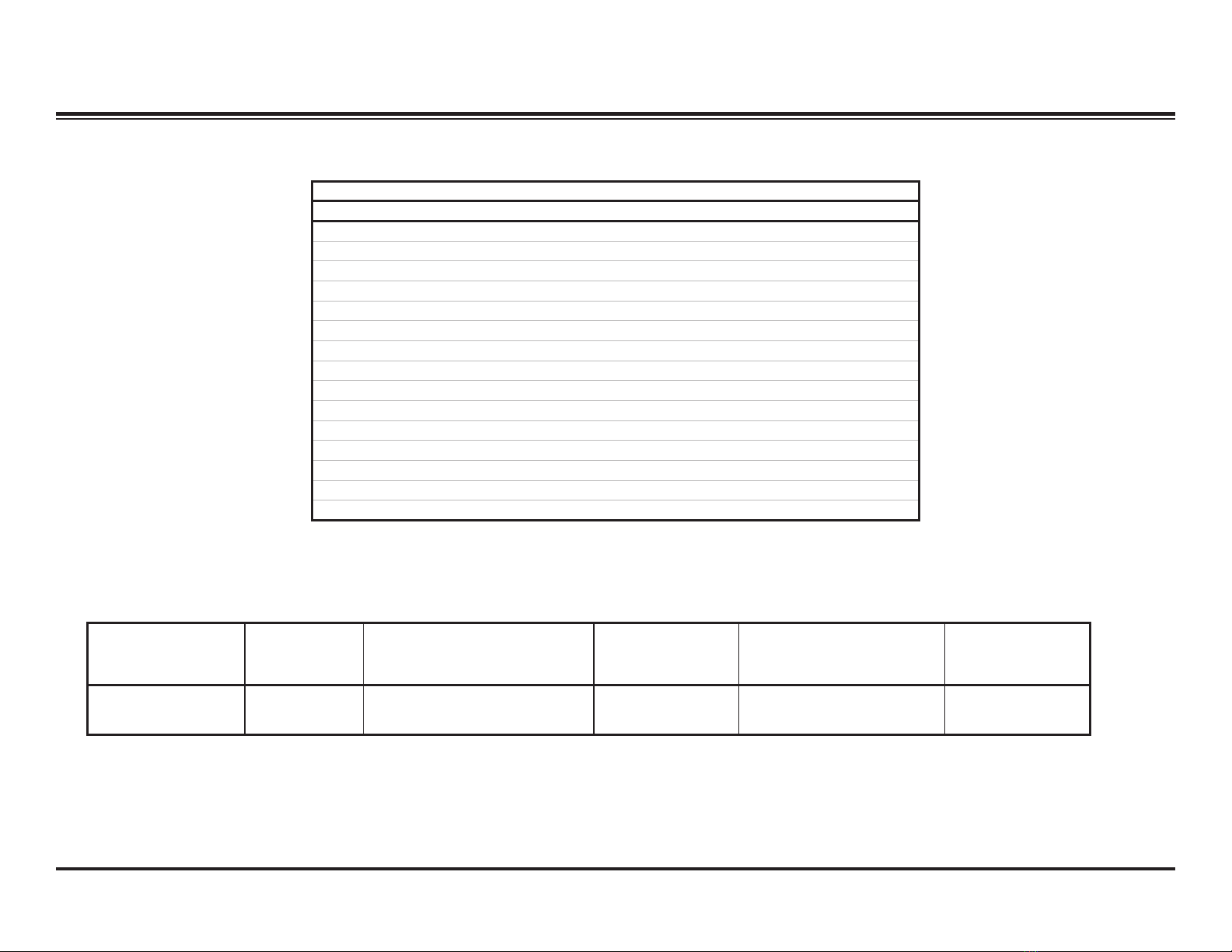

PRODUCT SPECIFICATIONS.................................................................... 9–10

Electrical System – Approximate Values ....................................................9

FloStat®Hydraulic System ...........................................................................9

Hydraulic Fastener Torque Specications .................................................10

Relief Valve Specications.........................................................................10

BLADE, A-FRAME & LIFT FRAME..........................................................11–13

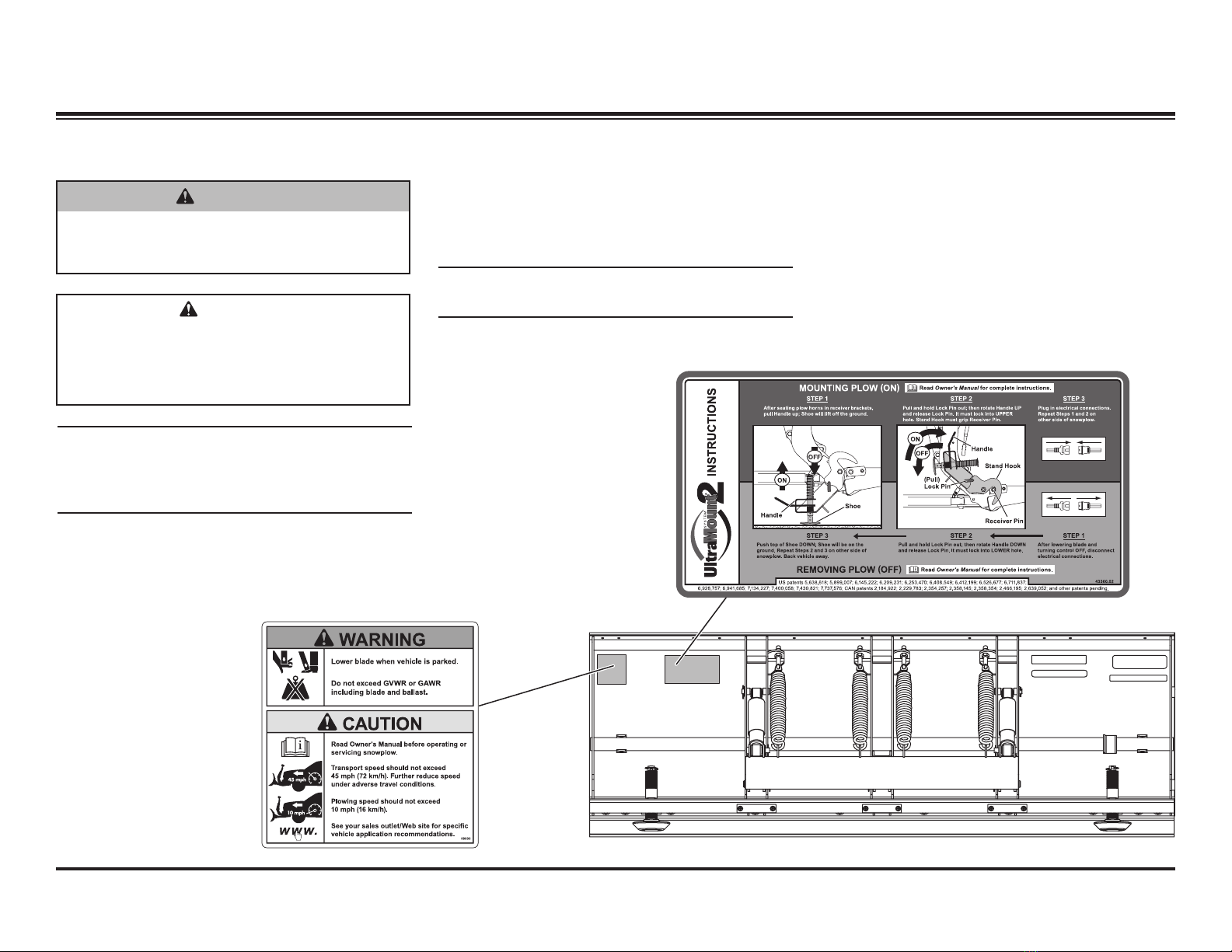

Pivot Plate Conguration – UltraMount®...................................................11

Stand Shoe Height Adjustment – UltraMount...........................................11

Attaching A-Frame to Lift Frame – UltraMount®2 ....................................12

Stand Shoe Height Adjustment – UltraMount 2........................................13

OPERATIONAL ADJUSTMENTS.............................................................14 –17

Filling the Hydraulic Unit ............................................................................14

Blade Drop Speed Adjustment ..................................................................15

Vehicle Lighting Check ..............................................................................16

Headlamp Beam Aiming ............................................................................17

HYDRAULIC SYSTEM OVERVIEW......................................................... 18–24

FloStat Hydraulic Unit Components...........................................................18

Pilot-Operated (Poppet-Style) Check Valves.............................................19

Hose Routing .............................................................................................19

Hoses and Fittings Installation.................................................................. 20

Ram Seal Installation................................................................................ 20

Cartridge and Check Valve Removal.........................................................21

CONTROLS .............................................................................................. 22–30

Overview ................................................................................................... 22

Solenoid Joystick Control ......................................................................... 23

CabCommand Hand-Held Control.............................................................24

Joystick Control – FLEET FLEX System ..................................................25

CabCommand Hand-Held Control – FLEET FLEX System .....................27

SECURITY GUARD™ Snowplow Anti-Theft System ................................28

THEORY OF OPERATION....................................................................... 31–33

Snowplow Hydraulics.................................................................................31

3-Port Module Electrical ............................................................................31

Green Label Module (PN 29070-1) .......................................................32

Blue Label Module (PN 29760-1)......................................................... 33

ELECTRICAL & HYDRAULIC SCHEMATICS..........................................35 –74

Legend .......................................................................................................37

3-Plug System – Wiring Overview........................................................... 38

3-Plug System – Electrical Connectors.................................................. 39

3-Plug System Schematics....................................................................... 40

Electrical Schematic ............................................................................ 40

Low-Beam Headlamps with Snowplow Connected to Vehicle .............41

High-Beam Headlamps with Snowplow Connected to Vehicle ............42

Hydraulic Schematic ............................................................................ 43

Raise – Electrical ................................................................................ 44

Raise – Hydraulic ................................................................................ 45

Lower/Float – Electrical....................................................................... 46

Lower/Float – Hydraulic .......................................................................47

Angle Right – Electrical....................................................................... 48

Angle Right – Hydraulic ...................................................................... 49

Angle Left – Electrical......................................................................... 50

Angle Left – Hydraulic..........................................................................51

Hold in Raise Position – Hydraulic.......................................................52

Striking an Object While Plowing – DS............................................... 53

Striking an Object While Plowing – PS ............................................... 54