7

Form No. 13629 September 1,1999

ASSEMBLY INSTRUCTIONS

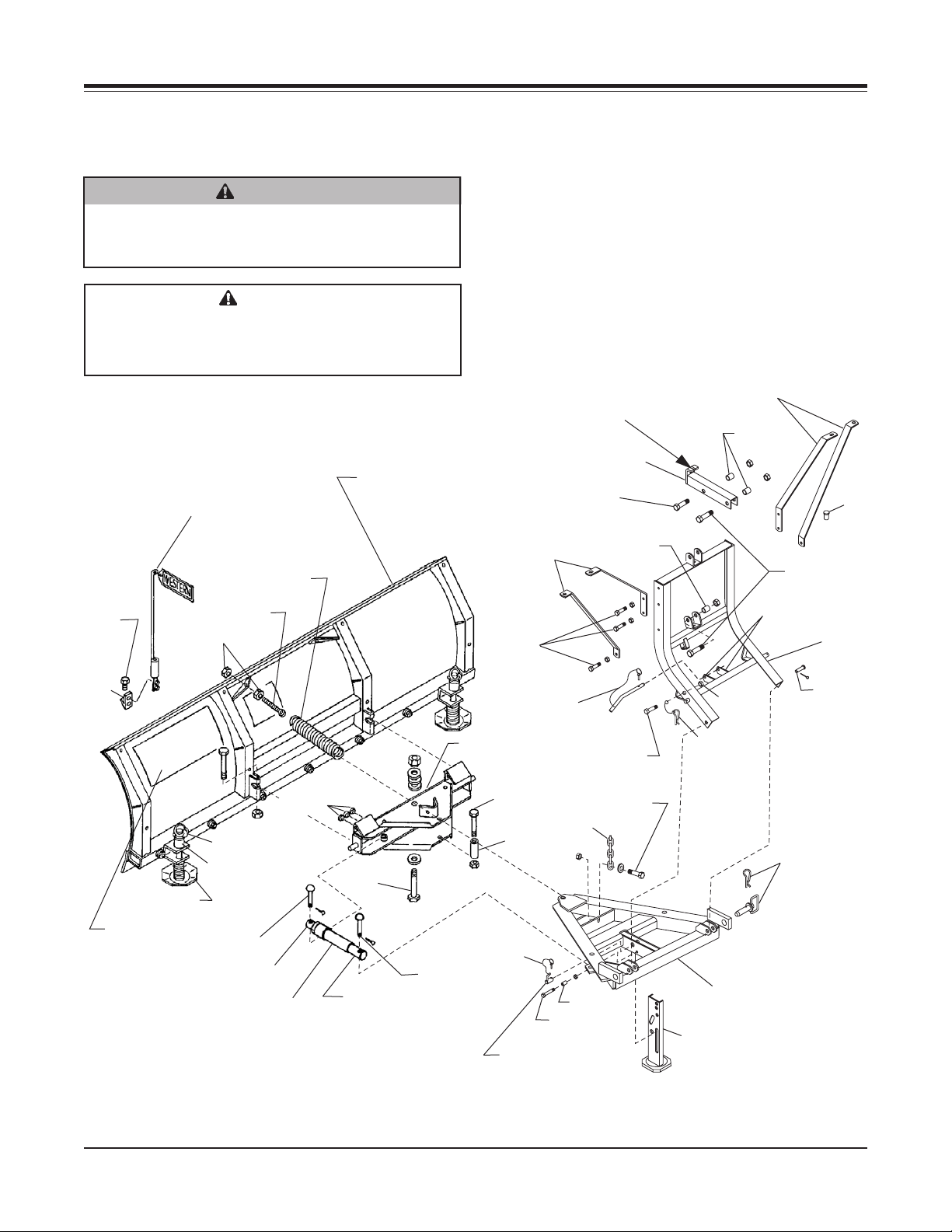

Assembling Lift Channel and Hydraulic

Unit To Lift Frame

1. Place the hole end of the lift channel between the

lugs of the upper U-bracket on the lift frame. Insert

a 3/4’’ x 3-3/4’’ bolt and secure with a .50” long

spacer and locknut. DO NOT OVERTIGHTEN - lift

channel must pivot freely.

2. Position the hydraulic unit (found in hydraulics

box), with the nameplate towards the blade, and

with the base lug between the lugs of the lower

U-bracket on the lift frame. Attach with a 3/4’’ x

3-3/4’’ bolt, a .69 long spacer, and a locknut. DO

NOT OVERTIGHTEN - hydraulic unit must pivot

freely.

3. Align hole in hydraulic unit lift ram with hole near

hook on lift channel and attach with a 3/4’’ x 3-1/4’’

bolt, a .50 long spacer, and a locknut. DO NOT

OVERTIGHTEN - lift channel must pivot freely.

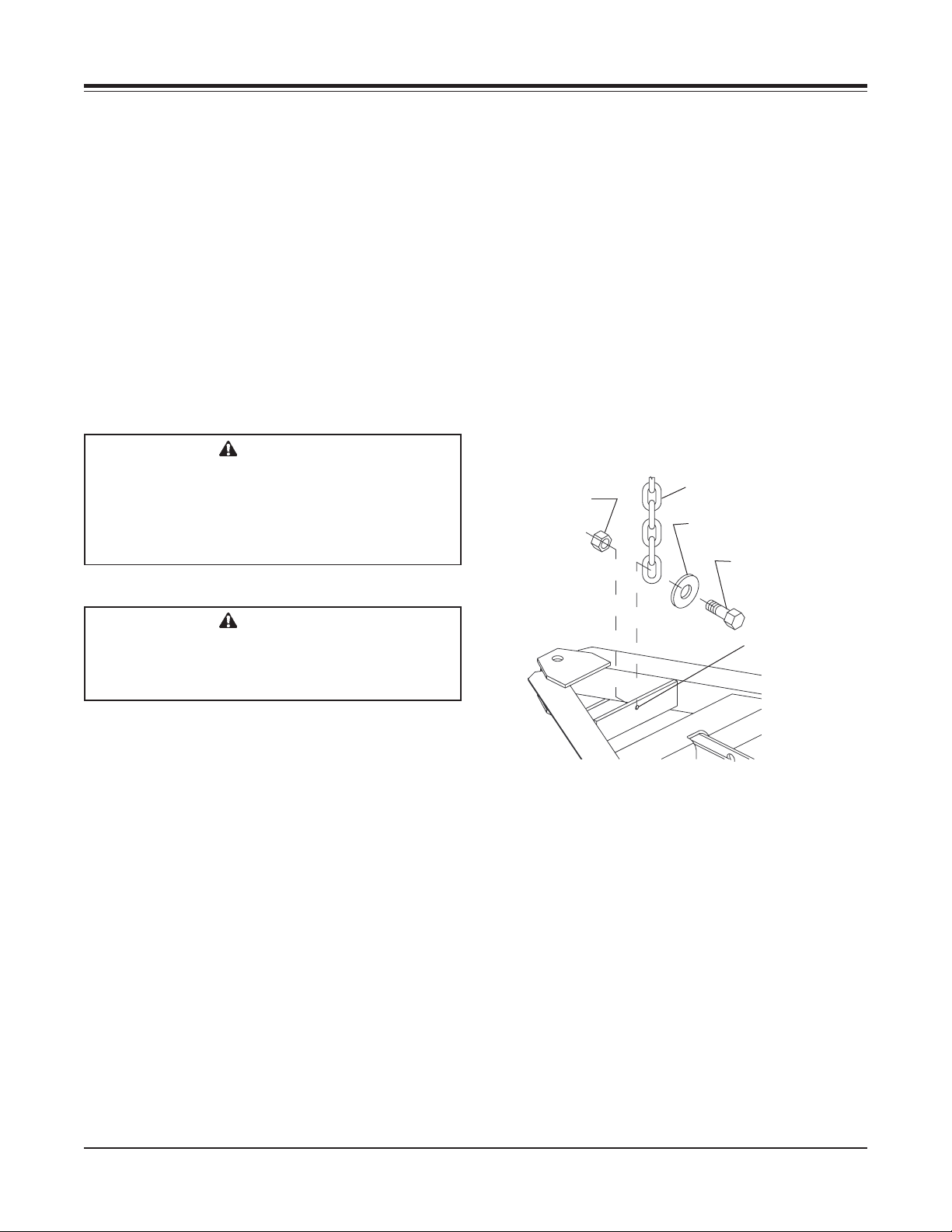

4. Place second link of chain into hook of lift channel.

(Final chain adjustment will be made after plow is

mounted on vehicle.)

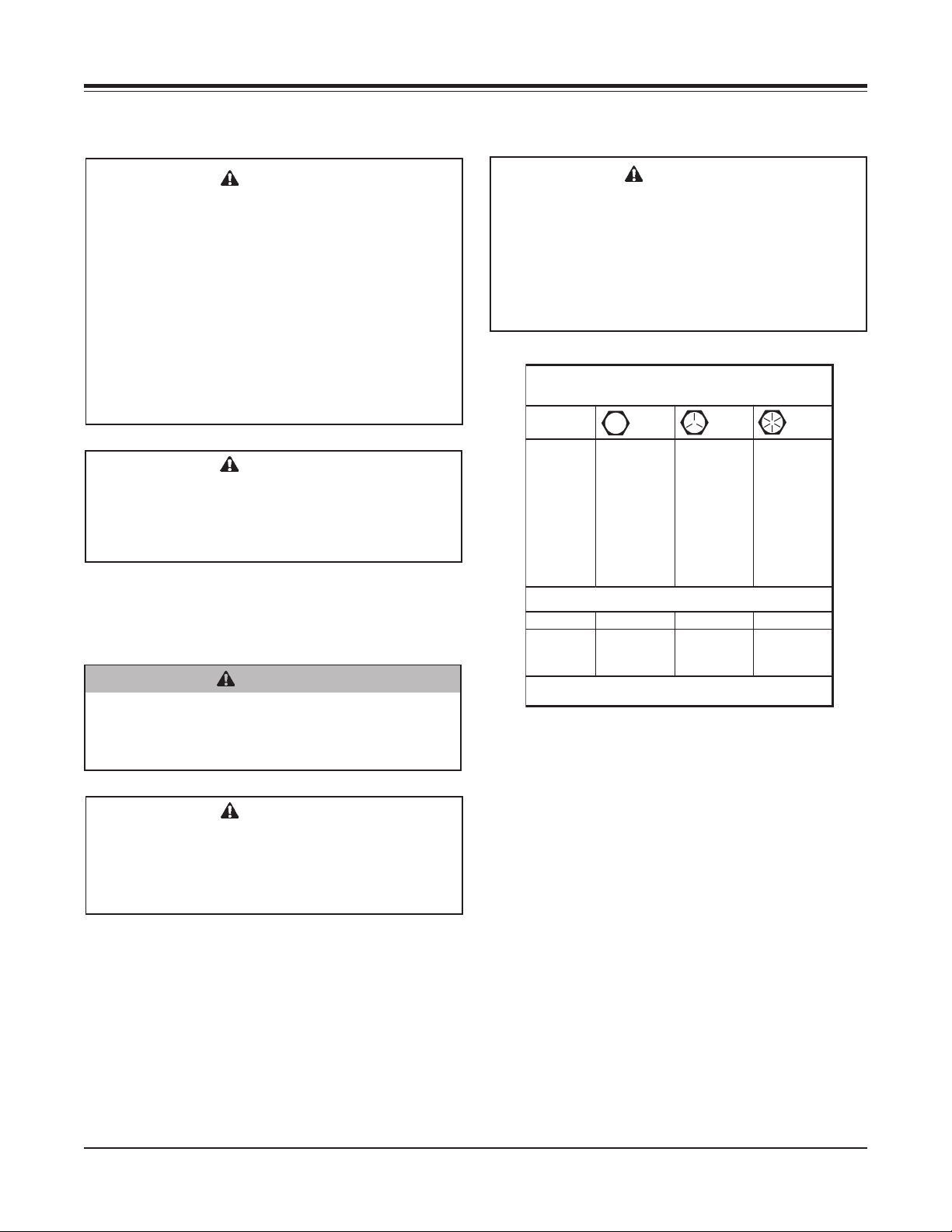

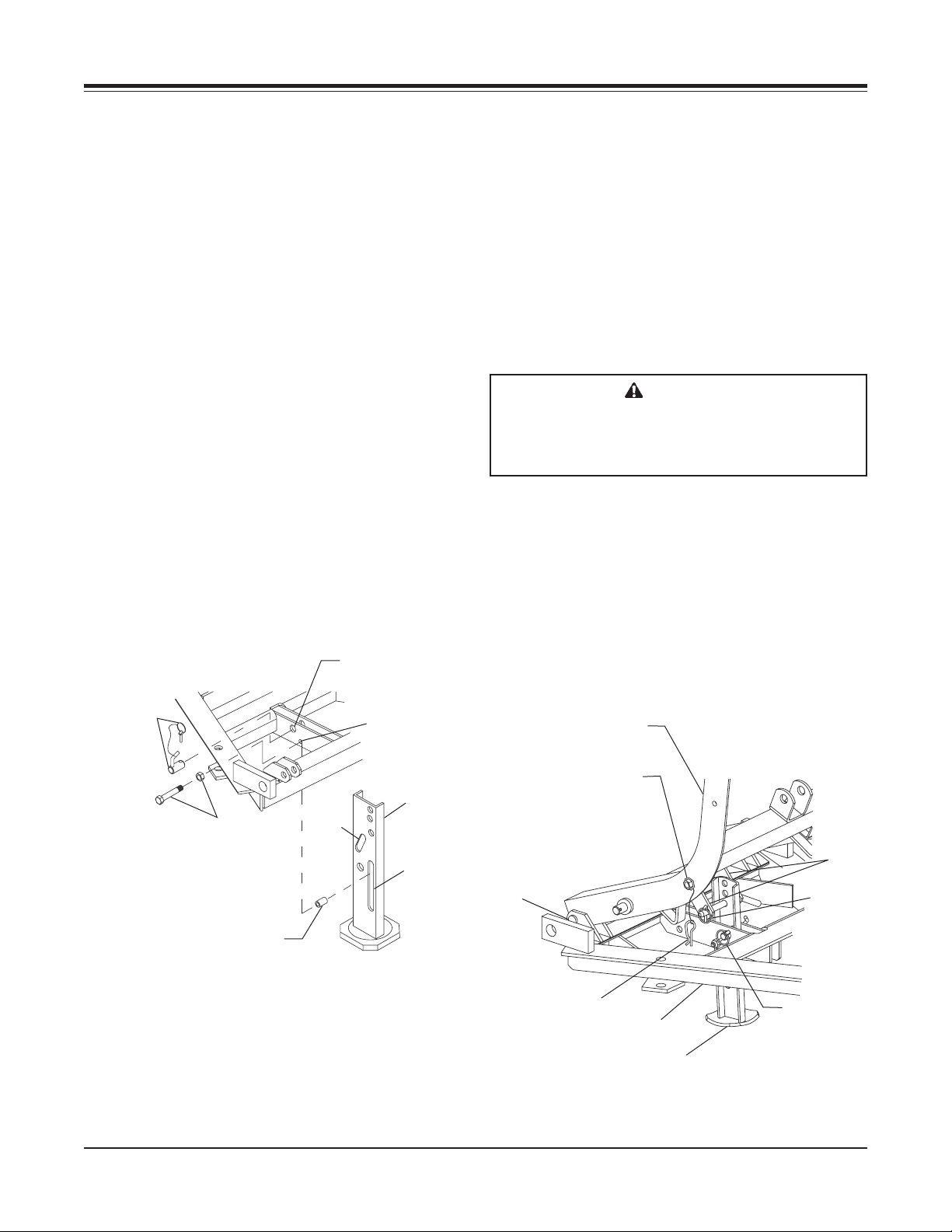

Assembling Hydraulic Fittings and Hoses

1. (Hoses and fittings are in the hydraulics box.)

Remove top two 1/4’’ pipe plugs from front face of

valve on hydraulic unit. Install two 45° swivel

fittings into pipe plug holes. Tighten fittings so the

hose connections will be straight down in line with

valve body. (See Figure 5.)

2. Install a 1/4’’ street elbow into the threaded port in

base end of each Hydra-Turn® ram. Tighten

fittings so they are oriented 45° from vertical

towards the blade. (See Figure 5.)

3. Install a hose into the street elbow on each Hydra-

Turn ram. Tighten each hose.

4. Route both hoses in front of lift frame and from

passenger side to driver side through hose loop on

middle cross angle of lift frame.

5. Attach hoses to 45° swivel fitting on hydraulic unit

as follows:

•Passenger side hose to rear 45° swivel fitting.

•Driver side hose to front 45° swivel fitting.

Remove twists from both hoses and tighten swivel

connections.

DO NOT use pipe tape/sealant when connecting hoses

to swivel fittings.

Front 45

°

Swivel Fitting

Rear 45

°

Swivel Fitting

Passenger Side Hose

Driver

Side Hose

Lift Frame Hose Loop

Driver Side Hydraulic Hose

(To Front 45

°

Swivel Fitting)

1/4" Street Elbow

(Typical Orientation Each Side)

1/4" Street Elbow

Passenger Side

Hydraulic Hose

(To Rear 45

°

Swivel Fitting)

Figure 5

Hydraulic Fitting Orientation and Hose Routing