Lit. No. 28270, Rev. 00 July 1, 2005

3

TABLE OF CONTENTS

Introduction .................................................................................................... 4

Preface ...................................................................................................... 4

Required Tools ......................................................................................... 4

Available Service Items ........................................................................... 4

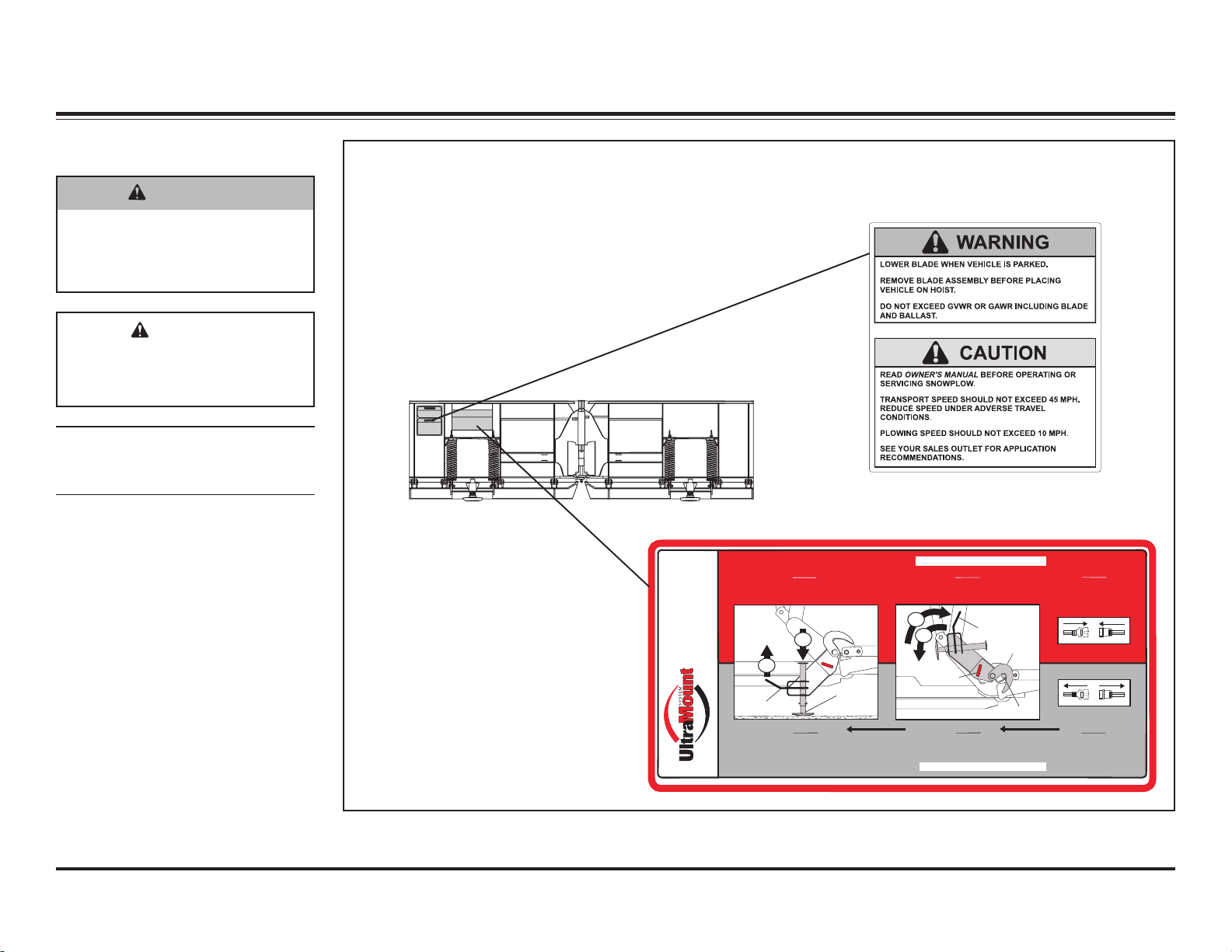

Safety Information .......................................................................................... 5

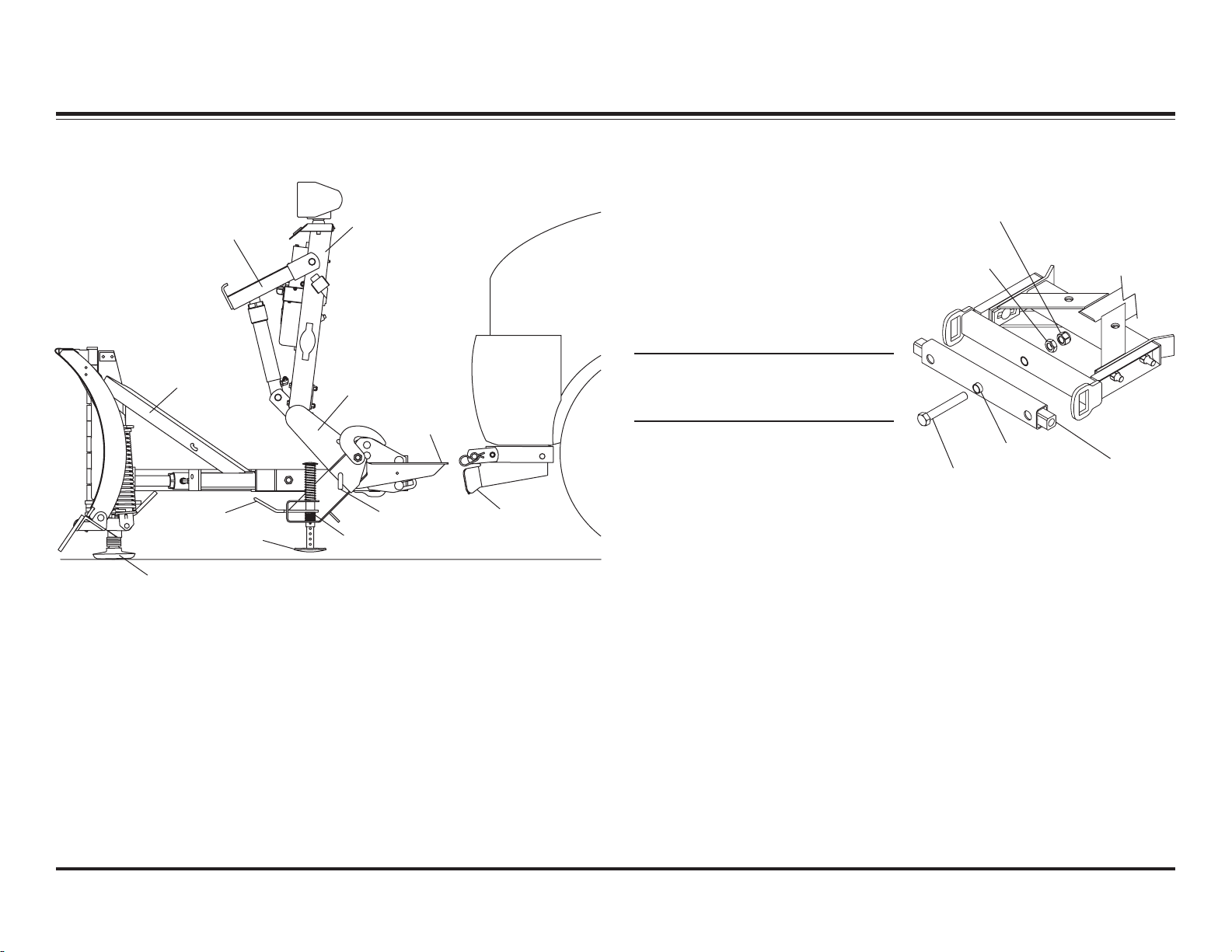

System Overview............................................................................................ 8

Blade, T-Frame & Lift Assemblies .......................................................... 8

Snowplow Components .................................................................... 8

Securing Pivot Bar to T-Frame ......................................................... 8

Pivot Plates ........................................................................................ 9

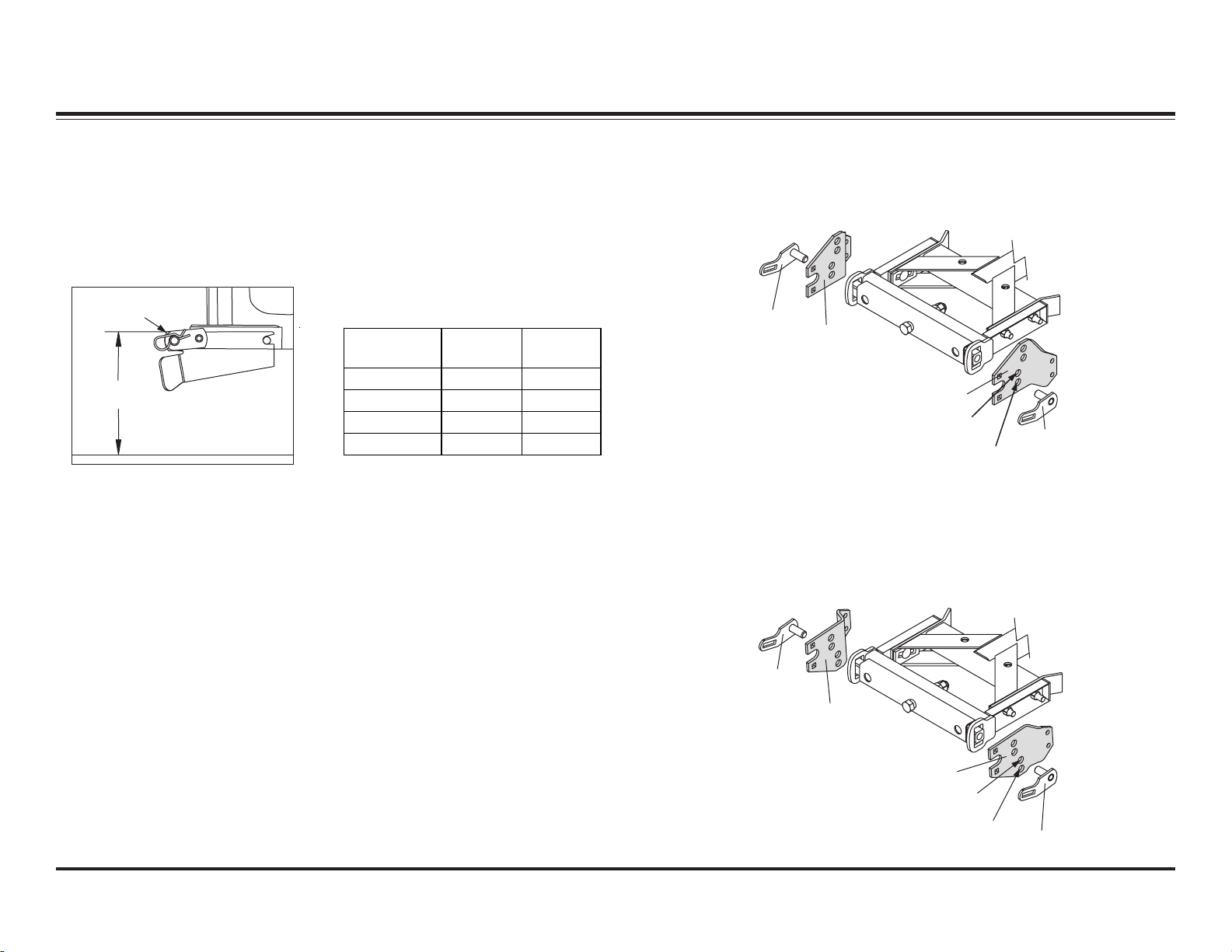

Initial Stand Shoe Setup .................................................................. 10

Stand Shoe Adjustment .................................................................. 10

Stacking Stop Configuration .......................................................... 11

T-Frame Leveling Adjustment ........................................................ 12

Blade Spring Replacement Tool (PN 20043) ................................. 13

Lift Arm & Lift Ram Installation ...................................................... 14

Headlamp Beam Aiming ................................................................. 15

Vehicle Lighting Check ................................................................... 15

Hydraulic ................................................................................................ 16

FloStat®Hydraulic System .............................................................. 16

Specifications .................................................................................. 16

Hydraulic Fitting and Hose Installation ......................................... 17

Hose Routing and Fitting Orientation ............................................ 18

Assembly ......................................................................................... 19

Cartridge Valves .............................................................................. 20

Relief Valves .................................................................................... 21

Pilot-Operated Check Valves .......................................................... 22

Ram Seal Installation ...................................................................... 23

Electrical ................................................................................................. 24

Wiring ............................................................................................... 24

Controls .................................................................................................. 25

General Information ........................................................................ 25

Adapter Cable (PN 66760K) ............................................................ 25

CabCommand Hand-Held Control (9 Button) ................................ 26

Joystick Control .............................................................................. 28

CabCommand Hand-Held Control (6 Button) ................................ 30

Fuse Replacement ........................................................................... 32

Terminal Removal Tool .................................................................... 33

Replacing Terminals ........................................................................ 33

14-Pin Connector Pin Assignments ............................................... 33

Theory of Operation ..................................................................................... 34

Snowplow Headlamps ........................................................................... 34

Snowplow Daytime Running Lights ..................................................... 34

Snowplow Hydraulics ............................................................................ 34

Electrical & Hydraulic Schematics.............................................................. 35

Electrical Schematic .............................................................................. 36

Hydraulic Schematic .............................................................................. 37

Raise ....................................................................................................... 38

Lower ...................................................................................................... 40

Angle Right ............................................................................................. 42

Angle Left ............................................................................................... 44

Vee .......................................................................................................... 46

Scoop ...................................................................................................... 48

Right Retract .......................................................................................... 50

Right Extend ........................................................................................... 52

Left Retract ............................................................................................. 54

Left Extend ............................................................................................. 56

Hold in Raised Position ......................................................................... 58

Striking An Object While Plowing ........................................................ 59

High Beam Headlamps with Snowplow Connected to Vehicle .......... 61

Low Beam Headlamps with Snowplow Connected to Vehicle ........... 62

Troubleshooting Guide ................................................................................ 63