1. DO NOT use this Smoker in a manner other than its intended purpose. It is NOT

intended for commercial use. It is NOT intended to be installed or used in or on a

recreational vehicle or boat.

2. For outdoor use only, DO NOT use indoors, in a garage, or in any other enclosed

area without proper ventilation.

3. Keepareextinguisheraccessibleatalltimes.

4. DONOTusetheSmokerwhileundertheinuenceofdrugsoralcohol.Theuse

of alcohol, prescription or non-prescription drugs may impair the operator’s ability to

properly assemble or safely operate the Smoker.

5. Use caution when assembling and operating the Smoker to avoid cuts and

scrapes from rough or sharp edges.

6. Use caution when lifting and moving the Smoker to avoid strains or back injury.

Two people are recommended to lift or move the Smoker. DO NOT move the Smoker

while it is in use.

7. DO NOT use the Smoker near or under ammable or combustible materials

such as decks, porches, or carpets. A minimum clearance range of 36 inches is

recommended. DO NOT operate the Smoker under overhead constructions. Operate

theSmokeronlyonastable,level,non-ammablesurfacesuchasasphalt,concreteor

solid ground.

8. DO NOT use the Smoker near gasoline or other combustible liquids or where

combustible vapors may be present.

9. DO NOT store or operate the Smoker in an area accessible to children or pets.

Store the Smoker in a dry, well protected area. NEVER leave the Smoker unattended

while it is in use.

10. THIS SMOKER BECOMES EXTREMELY HOT! DO NOT allow anyone to

conduct activities around the Smoker during or following use, until it has cooled. The

Smoker is hot during use and remains hot for a period of time following use. Allow

the Smoker to cool completely before moving or storing. DO NOT leave hot ashes

unattended until the Smoker cools completely. If you must move the Smoker while it

is hot, ALWAYS wear protective oven mitts or heat resistant gloves when handling the

Smoker or its components.

11. NEVERusegasolineorotherhighlyvolatileuidsasastarter.TheycanExplode.

12. The Water Bowl and Wood Chip Box should not be moved while the Smoker is

operating,oruntiltheSmokerhascooledsufciently.Thesecontainhotashesand

liquids that may cause serious injury! If you must move these components, ALWAYS

wear protective oven mitts or heat resistant gloves.

13. Dispose of cold ashes by wrapping them in heavy duty aluminum foil and putting

them in a non-combustible container. Be sure there are no other combustible materials

in or near the container. If you must dispose of the ashes before they have completely

cooled, remove the ashes from the Smoker, keeping them in a heavy duty foil, and soak

them completely with water before disposing of them in a non-combustible container.

14. Use caution when opening the Door of the Smoker while in operation. Keep

hands,face,andbodysafefromhotsteamorare-ups.Protectyournoseandmouth

from smoke inhalation.

15. DO NOT wear loose clothing while operating the Smoker. Tie back long hair

while operating the Smoker. ALWAYS wear fully-covering shoes while operating the

Smoker.

GENERAL SAFETY RULES

WARNING!

READ AND FULLY UNDERSTAND ALL INSTRUCTIONS AND WARNINGS PRIOR TO USING

THIS APPLIANCE. YOUR SAFETY IS MOST IMPORTANT! FAILURE TO COMPLY WITH

PROCEDURES AND SAFE GUARDS MAY RESULT IN SERIOUS INJURY OR PROPERTY

DAMAGE. REMEMBER: YOUR PERSONAL SAFETY IS YOUR RESPONSIBILITY!

16. Allow Smoker and its components to cool completely before conducting routine

cleaning or maintenance.

17. NEVER use glassware, plastic, or ceramic cookware on or in your Smoker.

18. NEVER operate the Smoker without water in the Water Bowl. NEVER allow the

water to completely evaporate. Check the water level at least every 2 hours. A sizzling

sound may indicate a low water level. Follow instructions in this manual for adding

water while operating.

19. Whenusingavoringwood,adda sufcientamountprior tooperationtoavoid

having to add wood while in operation. Adding wood while operating may splash hot

water and cause serious injury.

20. Use of accessories not intended for this Smoker is not recommended and may

lead to injury or property damage.

21. An LP gas cylinder not connected for use should not be stored in the vicinity of

the Smoker or any other appliance. DO NOT store spare LP gas cylinders within 10

feet of the Smoker. LP gas cylinders must be stored outdoors, out of reach of children.

DO NOT store LP gas cylinders in a building, garage, or any other enclosed area. DO

NOT store LP gas cylinders inside or on top of the smoker. Improper storage of LP gas

cylinderscouldleadtoexplosion,re,and/orpersonalinjury.

22. While the Smoker is not in use, the gas must be turned off at the supply cylinder.

23. LP gasses are heavier than air, tend to pool and collect in low-lying areas, are

easilyignitedandarehighlyammable!Propercareandcautionshouldbeemployed

when dealing with any such fuels. The Smoker should be shut off and all supply valves

(on-piping or on fuel cylinders) should be closed in the event that the odor of unburned

gasisdetected.DONOTattempttousetheunituntilanygasleaksarexedand/or

the source of the unburned gas odor is accounted for.

24. DO NOT use the Smoker if the burner fails to light or fails to remain lit. Under such

conditions, gas should be shut off and fuel cylinders should be disconnected.

25. Use under high wind conditions that result in poor burner operation such as

blowingoutandaringshouldbeavoided.Ifrepositioningtheunitdoesnotimprove

operation under such wind conditions, the unit should be shut off until conditions are

more favorable for proper usage.

26. All installations are to conform to local codes. In the absence of local codes,

installation should conform to the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

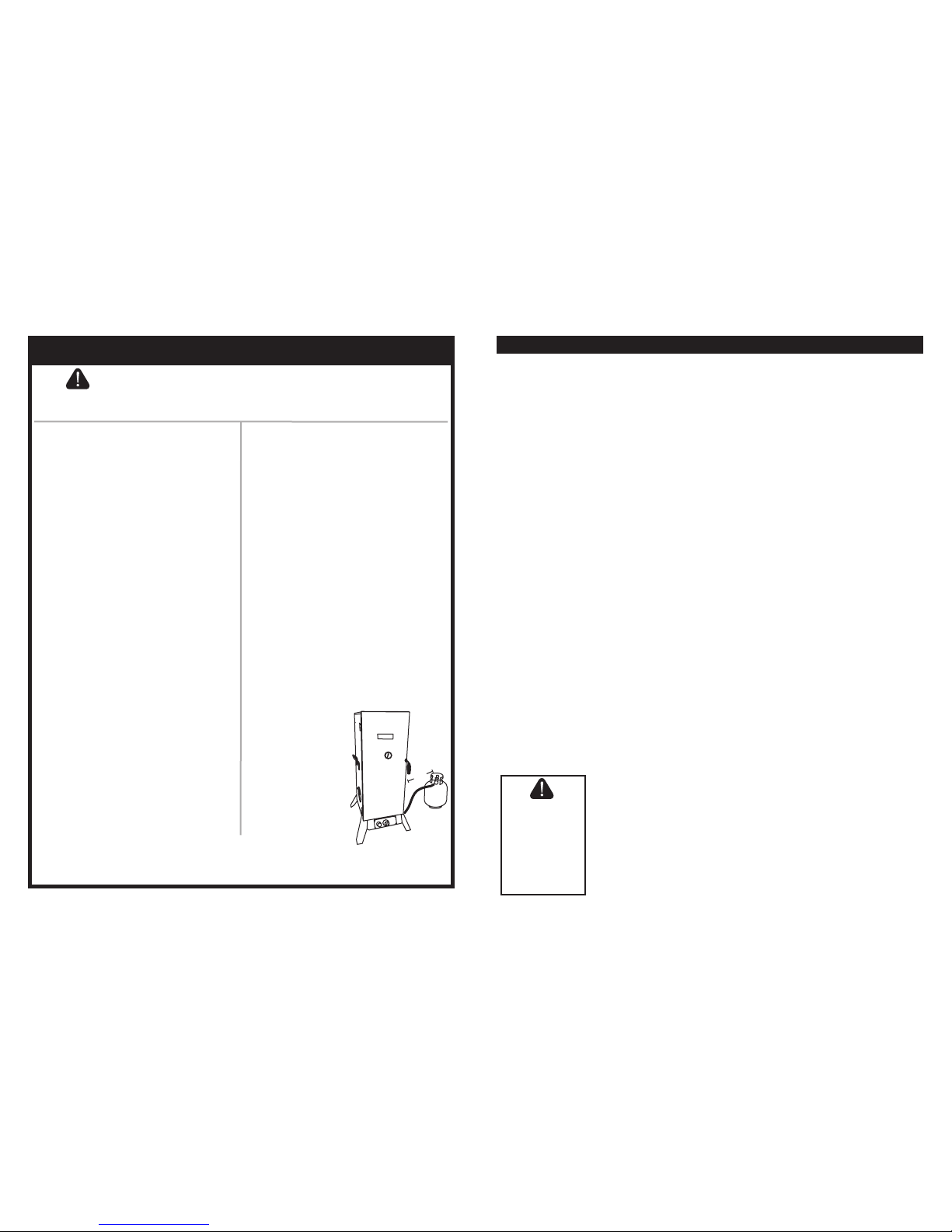

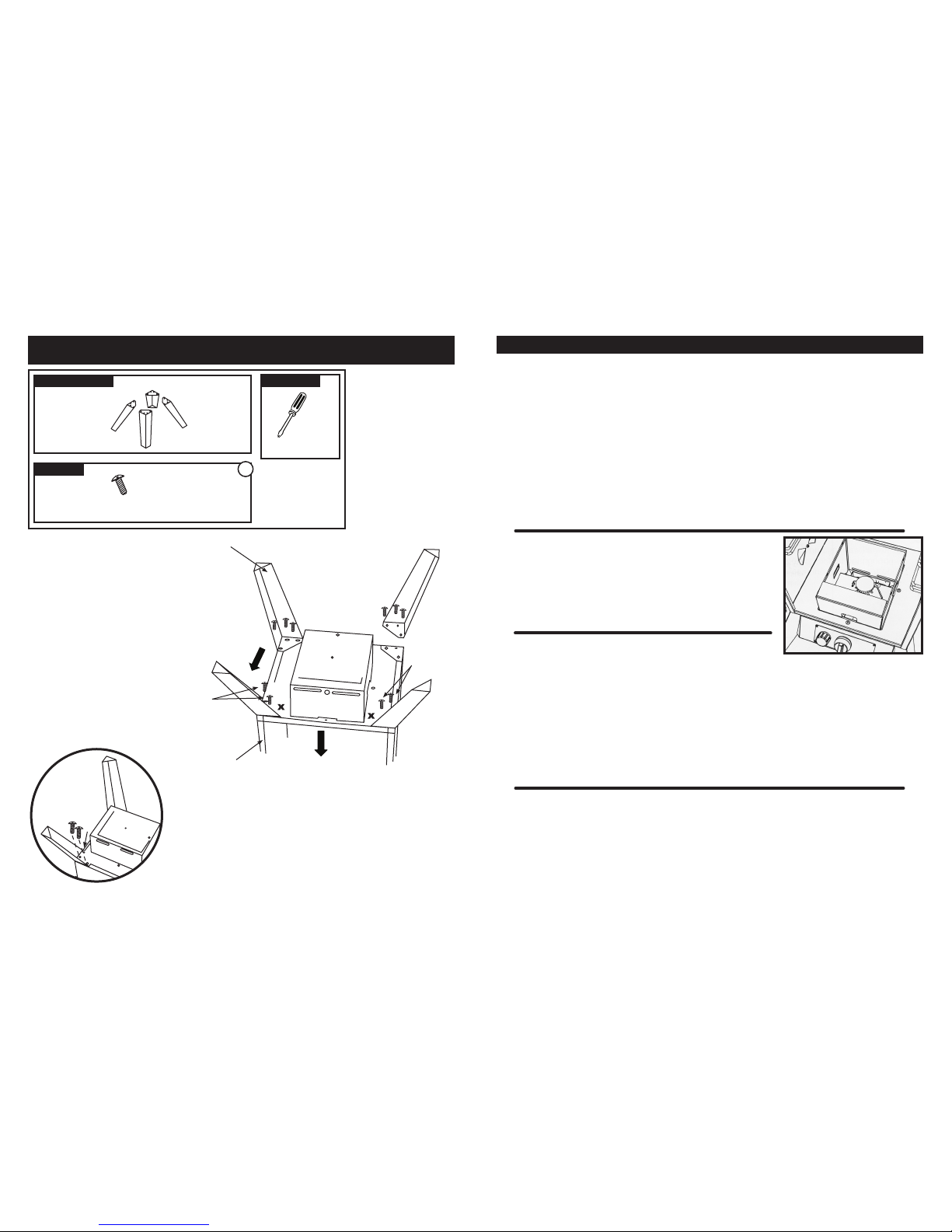

27. The Smoker should be installed with

the hose regulator assembly extended at

full length of hose directly (30”) away from

theburner.Whensocongured,placement

results in maximum tank to Smoker

distance. When the Smoker is operated,

the hose/regulator and gas tank should be

on a line perpendicular to wind direction.

Placing tank closer than 30” to the Smoker

can overheat the tank and cause release of

propane through relief openings and can

resultintankreorexplosion.

SAVE THESE INSTRUCTIONS.

USE CAUTION AND COMMON SENSE WHEN OPERATING YOUR SMOKER. READ ALL INSTRUCTIONS,

WARNINGS AND SAFEGUARDS BEFORE ASSEMBLING AND OPERATING YOUR SMOKER.

AFTER USE SAFETY & MAINTENANCE

!Use caution when lifting and moving the Smoker to avoid strains or back injury. Two people are recommended to lift or move the

Smoker.

!Dispose of cold ashes by wrapping them in heavy-duty aluminum foil and putting them in a noncombustible container. Be sure there

are no other combustible materials in or near the container.

!If you must dispose of the ashes in less time than it takes for them to completely cool, remove the ashes from the Smoker, keeping

them in heavy duty foil, and soak them completely with water before disposing of them in a noncombustible container.

.CAUTION : All care and maintenance procedures are to be performed only while the Smoker is turned off and cooled.

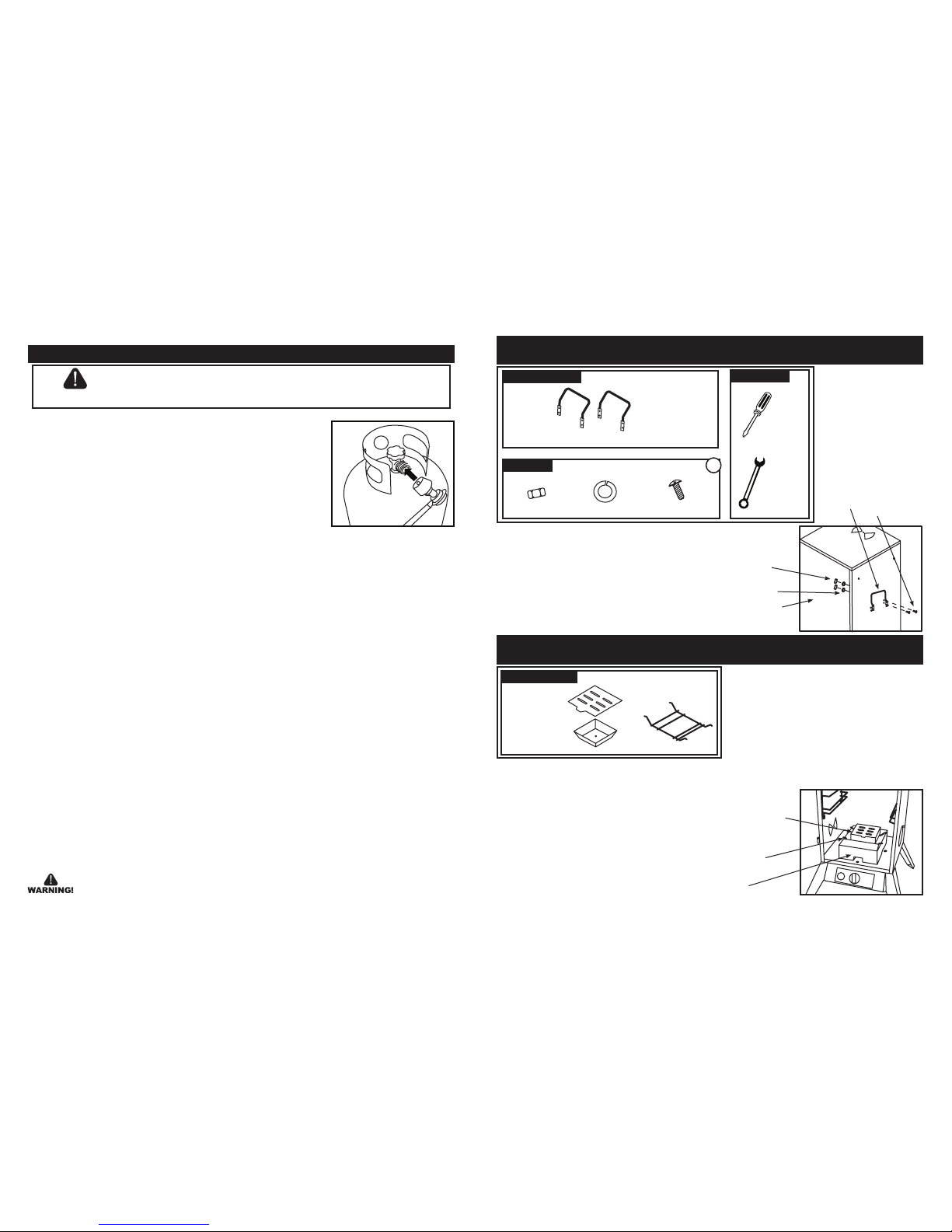

.Clean the Water Bowl and Cooking Racks with hot, soapy water. Rinse and dry thoroughly. You may prefer to coat the Water

Bowl and Cooking Racks lightly with cooking oil or cooking spray.

. Frequently check and clean the Venturi and Burner for insects and insect nests. A clogged tube can lead to re outside the smoker.

. Check to be sure the Heat Indicator remains accurate. Simply loosen and remove the mounting nut from the inside. There is a

second nut mounted on the back of the Heat Indicator that can be turned to adjust the Heat Indicator Needle. Set the needle to the

current outdoor ambient temperature and re-mount the Heat Indicator to the Door of the Smoker.

.To clean the inside and outside of the Smoker Cabinet, simply use a damp cloth. Spray-washing with a water hose is not

recommended. All moisture should be wiped away and not allowed to stand inside or on top of the Smoker. Once cleaned, you

may prefer to lightly coat the interior of the Smoker Cabinet with cooking oil or cooking spray.

.If rust is present on the exterior surface of the Smoker, clean the area with steel wool or emery cloth and lightly coat the area with

cooking oil or cooking spray to help minimize recurring rust.

. When an LP tank is not connected, and to help prevent dirt or other foreign particles from clogging the HVR, hang the end of the

HVR hose from the side Handle using the supplied S-Hook, as reviewed in ASSEMBLY STEP 12.

. Inspect the ames at the Burner by looking through the front access hole. A good ame should be blue with a yellow tip up to 1”

in length. If ames are excessively yellow and irregular, oil residue and food deposits may be collecting on the Burner. Try cleaning

the Burner surface and the holes to improve the ames. Bad ames may also be caused by poor HVR-to-Venturi attachment.

Always let the Smoker cool before cleaning or checking the assembly.

.To protect your Smoker from weather, always keep your Smoker covered while not in use.

-4- -17-

+30”

Be sure to follow ALL SAFETY

WARNINGS and precautions

that are contained in this

instruction manual before

using this Smoker!

NEVER leave this appliance

unattended!

The Smoker becomes

EXTREMELY HOT!

When the Smoker is not in use,

the gas MUST BE TURNED

OFF at the supply cylinder.

WARNING!