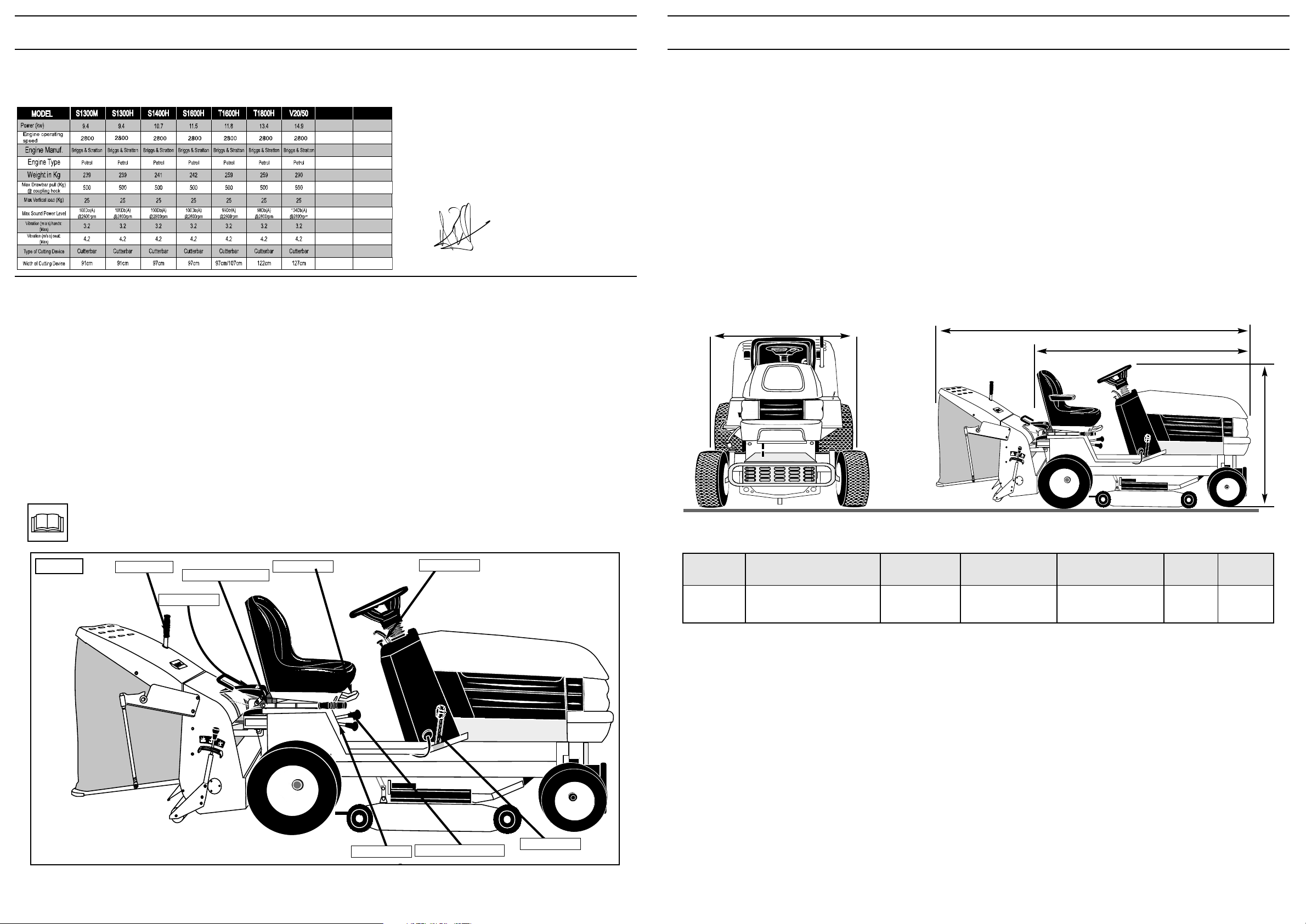

fig 17

The Headlight Switch

Electric Deck Lift

Troubleshooting (Cutter Levelling)

Levelling Side to Side

Tractors up to serial No. 41224

This adjustment is best done with the deck in a position three up

from its lowest cut – check the level both sides and levelling is

then achieved by adjusting the left side ( as you are sat on the

Tractor) of the deck at 2 points.

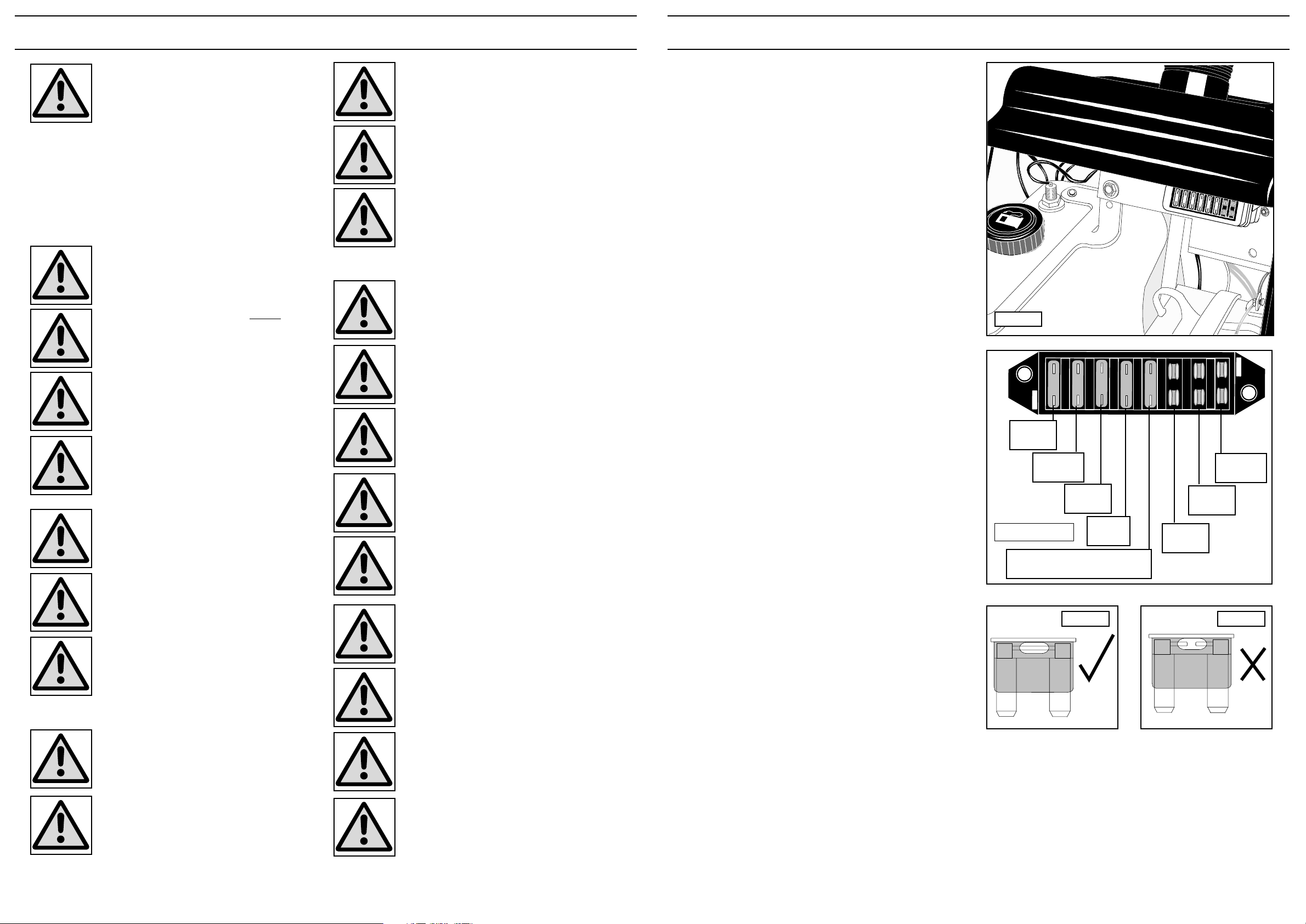

REAR ADJUSTMENT (Figure 38)

1. Find the Deck Level Disc (Figure 38) near the

back (near side) wheel. This has a concentric slot in

which the Deck Levelling Rod is located.

2. Using a 13mm spanner loosen the M8 Nyloc nut

(A) securing this stud just enough to permit some

movement.

3. Now lift or depress the Deck depending on the

adjustment you wish to achieve. This will move the

stud up or down the disc – the higher up and

nearer the centre of the disc the higher the deck.

4. Check with your ruler or tape and having levelled

the Deck at the rear re-tighten the Nyloc nut.

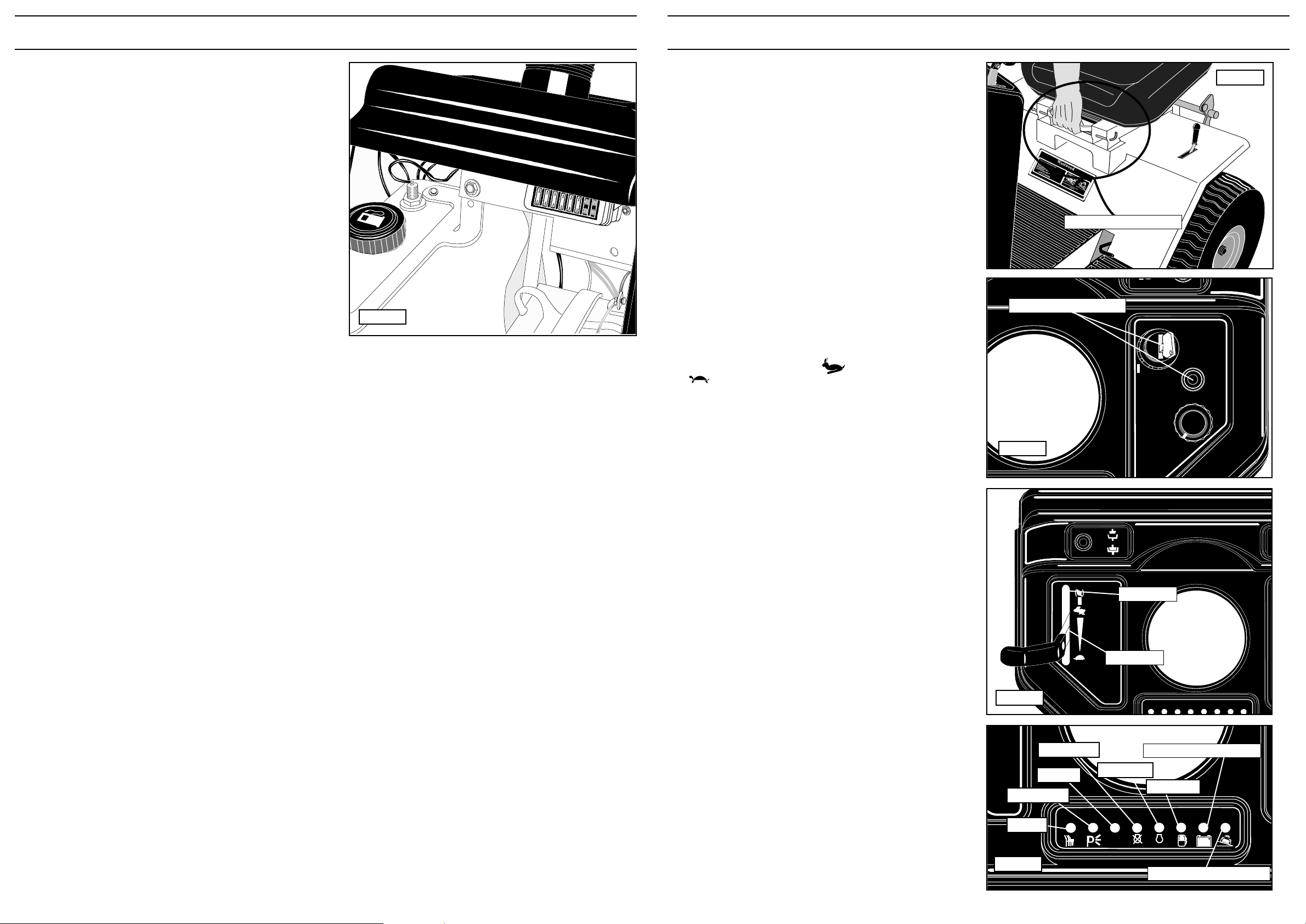

FRONT ADJUSTMENT (Figure 39)

1. Having levelled the rear of the Deck check if the

front is level. If not find the Deck Adjustment Plate

(Figure 39) which is forward of the Cutter Deck

near the front (left) wheel.

2. Before making adjustments loosen the two sets of

nuts and bolts (A & B).

3. Using a 13mm spanner loosen (upper) locknut (C).

4. Now adjust the height by using a ratchet or spanner to

turn the Nyloc nut (D) clockwise (up) to raise the

Deck or anti-clockwise (down) to lower it.

5. When level is achieved tighten lock nut (C)

re-tighten nuts and bolts A & B.

6. Raise and lower the cutter deck and then re-check level.

A

B

Deck Level Disc fig 38

Deck Adjustment Plate

B

A

D

C

fig 39

PGC Lift Lever (Fig 14)

Using the lever (figure 14) raise or lower the Powered

Grass Collector to either the Transport position or the

Collecting position. This lever is located on the right of the

driver on the S or T Series tractor and to the left of the

driver on the V20/50.

Power Take-Off - S/T Series (Fig 15)

To engage the PTO drive the PTO lever is lifted up out of

its locator moved to the left and released to find its own

height. To disengage the PTO pull the lever up and to the

right. Always have this lever in the ‘disengaged’ position

when it is not in use. DO NOT PUT HANDS NEAR

MOVING PULLEYS AND BELTS.

Power Take-Off - V20/50 (Fig 16)

To engage the PTO push the lever down and to the left

then release the lever upwards. The PTO lever is pushed

down and to the right into its locator to disengage. Always

have this lever in the ‘disengaged’ position when it is not

in use. DO NOT PUT HANDS NEAR MOVING PULLEYS

AND BELTS.

Lights (Fig 17)

Pressing the push button turns ON the headlights. Turn

the headlights OFF by pressing the button again.

The headlights will not operate without the ignition switch

turned on. NOTE: As an additional safety feature the

headlights will flash whilst the cutter deck is running

unless the lights are turned on.

RPM (Fig 5)

Your Westwood Tractor is equipped with an engine RPM

monitoring system to ensure that the correct engine speed

is maintained at all times. This consists of a green light

showing the engine is running above 2600 RPM which is

the minimum engine speed is recommended for good

grass cutting and collection. Below 2600 RPM the green

light will go out and a red one will illuminate next to it. If

during a mowing session the low RPM light comes on

then you must either raise the cutter deck or reduce your

mowing speed to allow the engine RPM to increase.

Electric Deck Lift (where fitted) -

(Figure 17)

The cutting height is adjusted by turning the rotary switch

anti-clockwise to lower the deck and clockwise to raise

the deck. The height indicator around the switch (Figure

17) shows the deck position (1-lowest to 10-highest).

To get the best from this refinement use it to continuously

adjust cutting height to suit ground and grass conditions.

Do not make downward adjustments on the move until

you are familiar with the height control this will avoid

“scalping” the lawn.

Page 17

DECK LEVEL SYSTEM FOR ‘S’ & ‘T’ SERIES

Tractors from serial No. 50104

Side to Side Level

This adjustment is best done with the deck in a position three up

from its lowest cut – check the level both sides and levelling is

then achieved by adjusting the left side (as you are sat on the

Tractor) of the deck at 2 points.

Rear Adjustment

Locate the top lock nut (A) and loosen this off using a 17mm

Spanner. Now wind the adjuster nut (B) either up or down using

a 19mm Spanner to alter the height of the deck on the left hand

side to match that on the right hand side. Use the marks on the

plate as a guide as to how much to raise or lower the deck.

When the deck is level at the rear tighten the lock nut securely

Front Adjustment

Locate the top lock nut (A) and loosen this off using a 17mm

Spanner. Now wind the adjuster nut (B) either up or down using

a 19mm Spanner to alter the height of the deck on the left hand

side to match that on the right hand side. Use the marks on the

plate as a guide as to how much to raise or lower the deck.

When the deck is level at the front tighten the lock nut securely.

Raise and then lower the cutter deck and then re-check the

level. If it is still incorrect re adjust as required

NOTE: 38, 44 and 0” Mulch decks must be set 10mm

higher at the front than the back

A

B

A

B

A

B

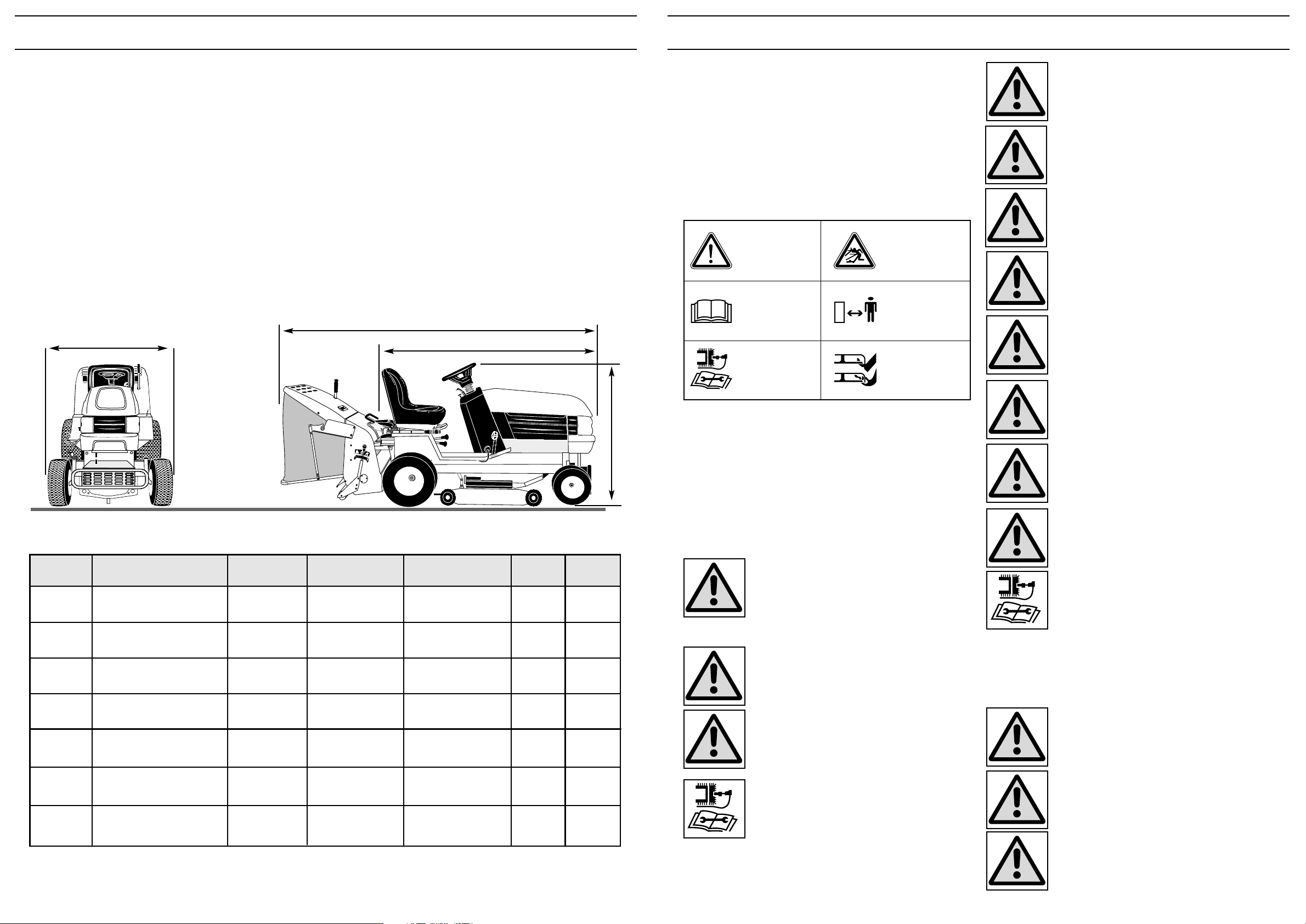

Manual Deck Lift

Electric Deck Lift

Front

Adjustment