Safety Instructions

Page 1

Training

1. Read the instructions carefully. Be familiar with controls and

the use of equipment.

2. Never allow children or people unfamiliar with these

instructions to operate the mower.

3. Never mow while people, especially children or pets, are

nearby.

4. The operator or user is responsible for accidents or hazards

occurring to other people or their property.

5. Do not carry passengers.

6. All drivers should seek to obtain professional and practical

instruction. In addition the following should be noted:

• The need for care and concentration when working

with this machine.

• Control of a tractor sliding on a slope; control will not

be regained by applying the brake.

• The main reasons for loss of control are:

i. Insufficient wheel grip

ii. Driving too fast

iii. Operating on steep slopes (max 15º)

iv. Incorrect load distribution

Preparation

1. Check that the machine complies with all applicable

regulations, including those in force when used on the

public highway.

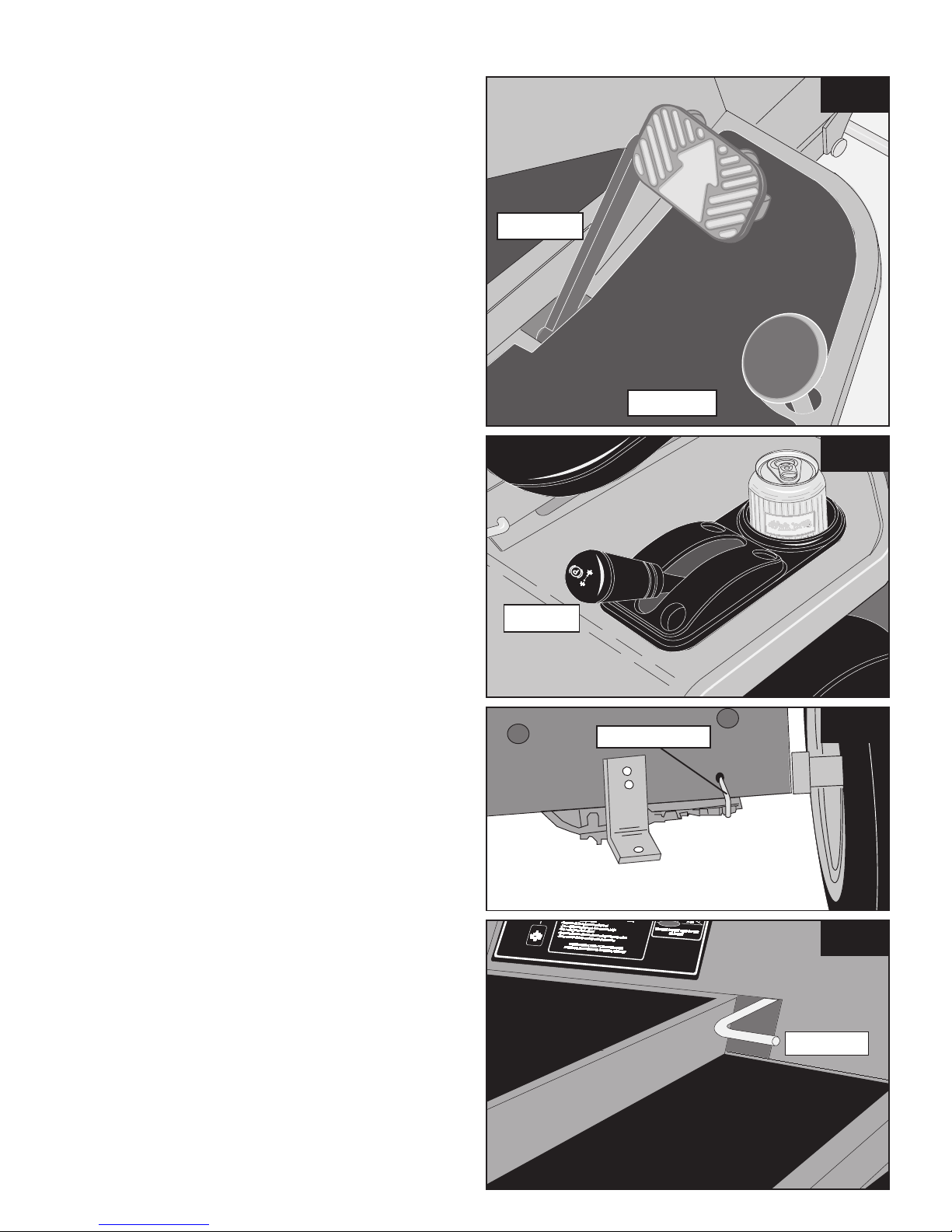

2. When mowing, always wear substantial footwear and long

trousers. Do not operate when barefoot or with sandals.

3. Thoroughly inspect the area where the tractor is to be used

and remove all stones, sticks, wires and bones or any

other foreign objects.

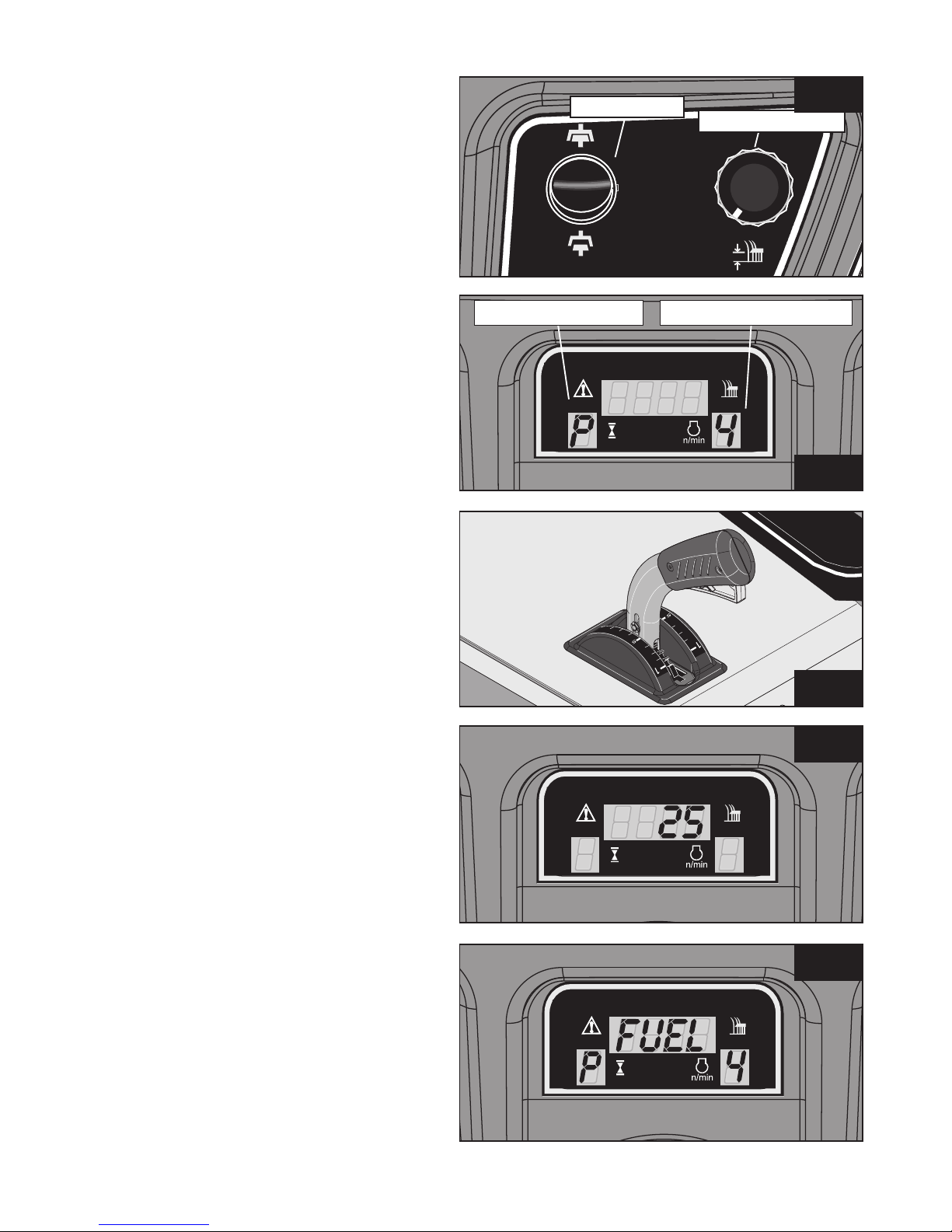

4. WARNING – petrol is highly flammable:

• Store fuel in containers specifically designed for this

purpose.

• Re-fuel outdoors only and do not smoke while

refuelling.

• Add fuel before starting the engine. Never remove the

cap from the fuel tank or add diesel while the engine is

running or when engine is hot.

• If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until petrol or

diesel vapours have dissipated.

• Replace the fuel cap securely.

5. Replace faulty silencers.

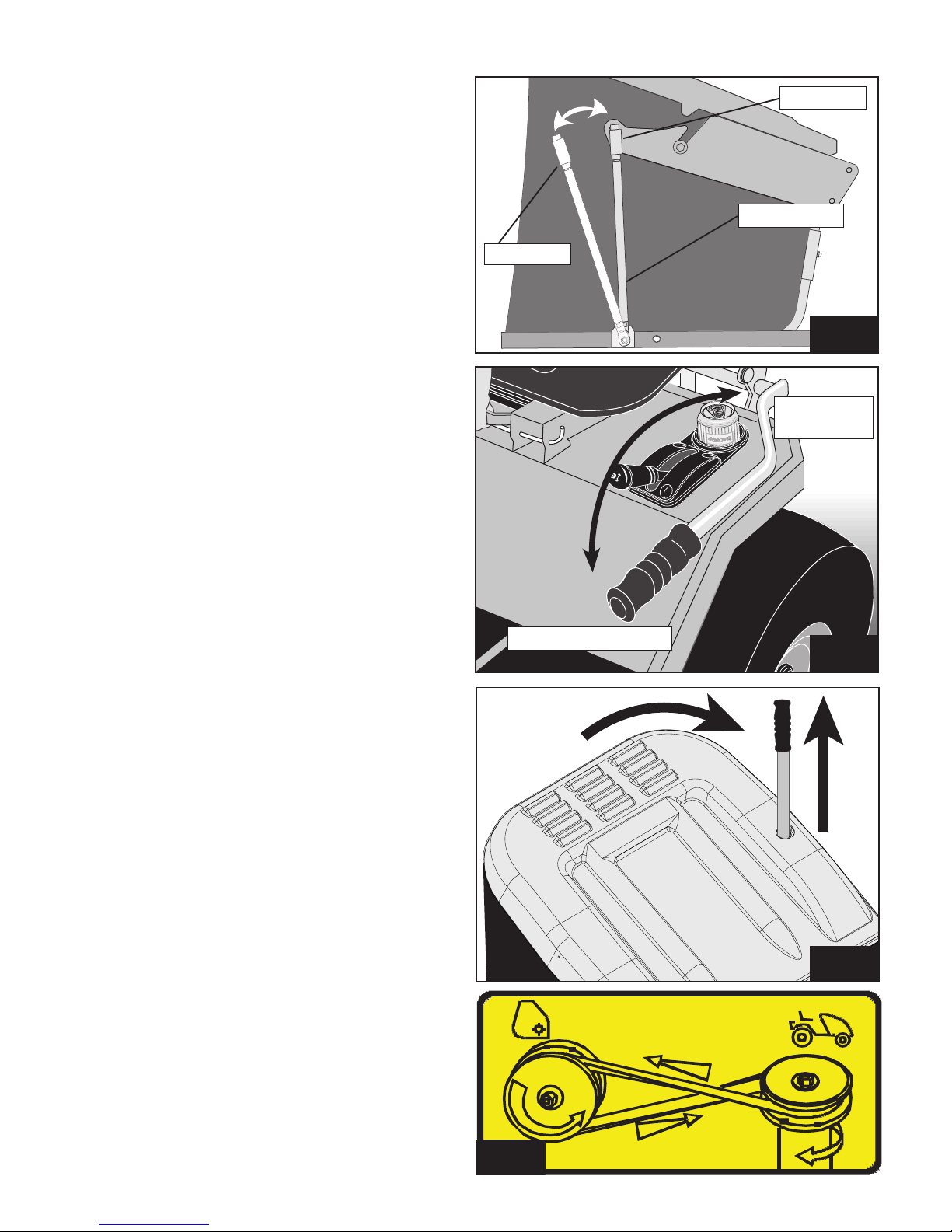

6. Before using, always inspect to see that the blades, bolts and

cutter assembly are not worn or damaged.

7. Check the condition of the tyres and ensure that they are

inflated to the correct pressures (refer to pages 25-26).

This is particularly important if the machine is to be taken

on the public highway.

8. Check that the mower is in good working order, paying

special attention to brakes, steering, water and oil.

9. Check that all linkages, connections and pivot nuts are

secure and that the wheel nuts are tightened correctly.

Contents

Safety Instructions Page 1

Operating Instructions Page 2

Controls Page 3 – 8

Powered Grass Collector Page 9 – 10

Using your Tractor Page 11

Cutter decks Page 12 – 13

Routine maintenance Page 14 – 16

Troubleshooting:

Cutting Page 17

Cutter Levelling Page 18 – 19

Grass Collecting Page 20

Tyres & Wheels Page 21

Starting & Running Page 22

Electrics Page 23 – 24

Specifications Page 25 – 26

Personal Service Record Page 27

Certificate of Conformity Page 28

Please Note:

The information contained on this, and

the following pages is given on the

understanding that Westwood accepts

no responsibility for work carried out by a

customer or for any damage thus caused,

whether or not the service instructions have

been misunderstood. To be sure that your

warranty terms are not breached, service

work should only be carried out by your

dealer.