3

EKW FX10 INSTALLATION MANUAL

Table of Contents

General Installation Information.............................................4

Accessories & Other Options ................................................5

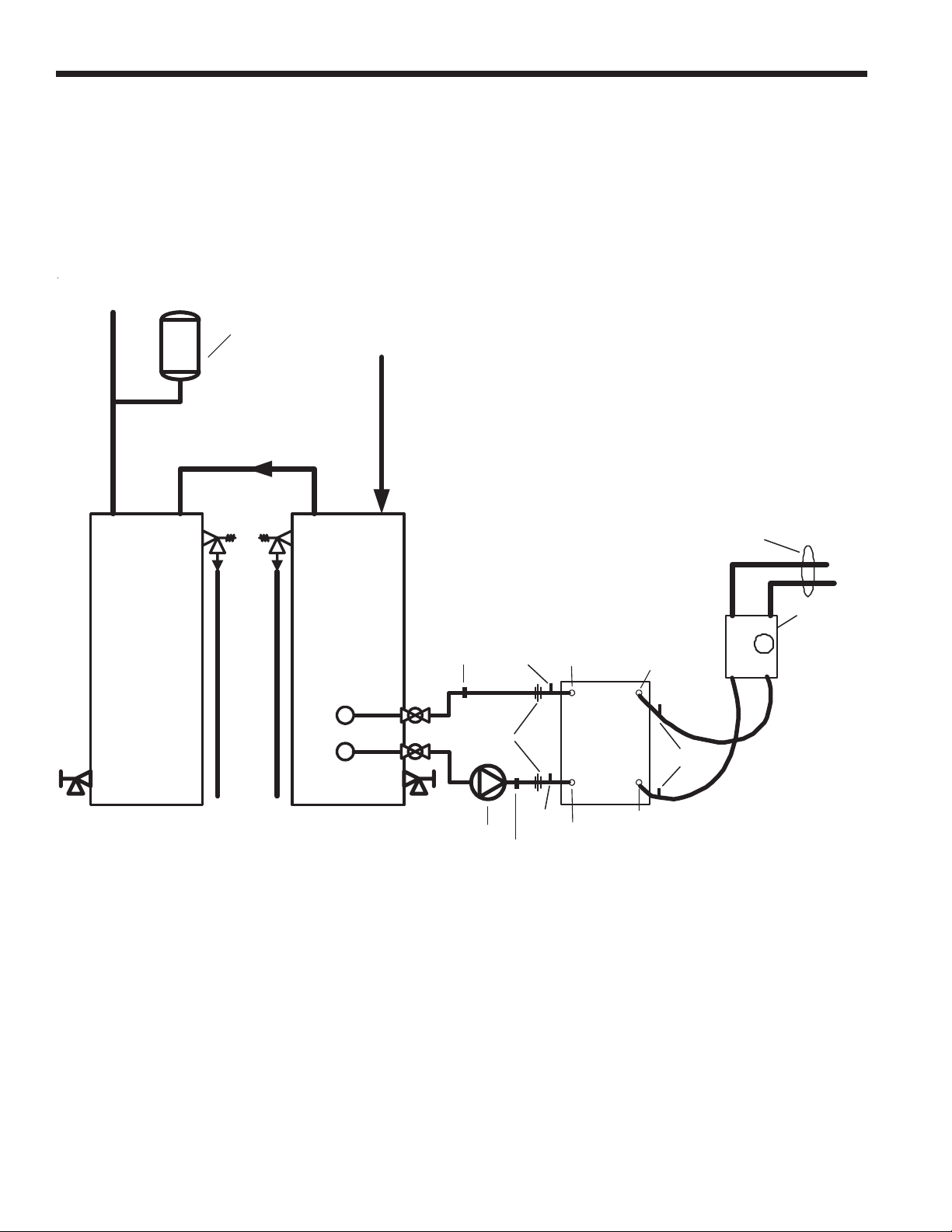

Potable Water Systems ......................................................6-7

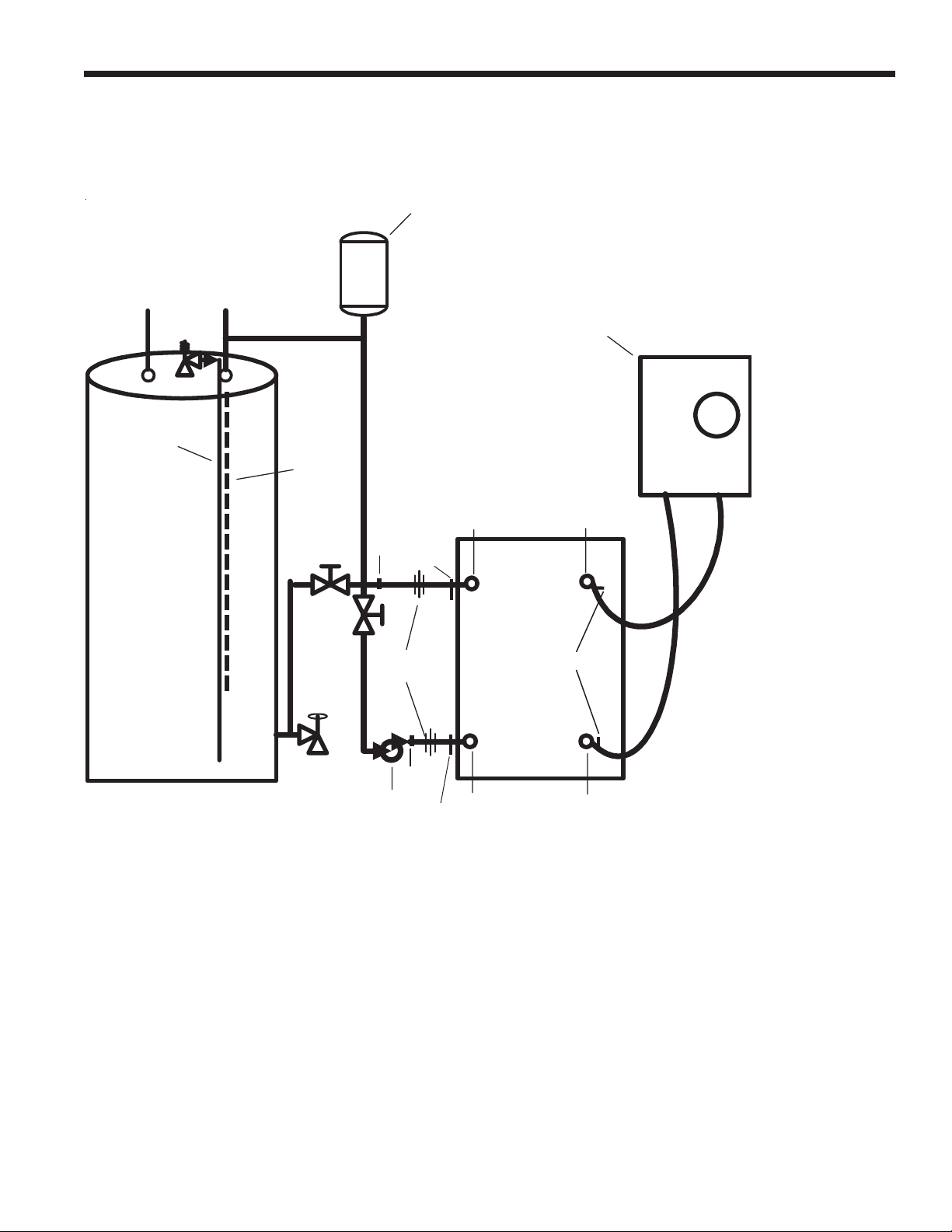

Open Loop Systems..............................................................8

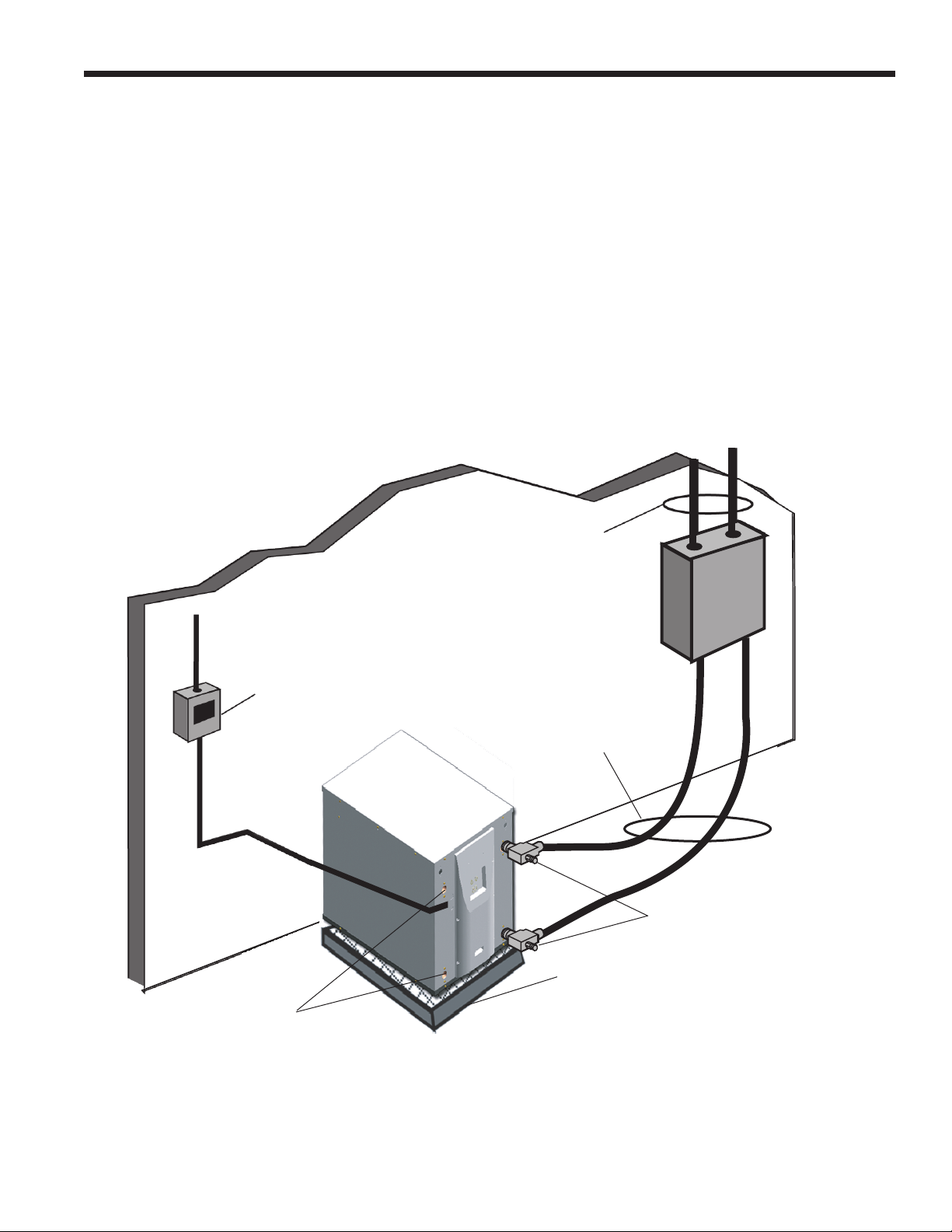

Earth Coupled Systems.........................................................9

Electrical..............................................................................10

Dimensional Data, Physical Elements, Sound Data............ 11

Electrical..............................................................................12

Small EKW Setup/Operation ..........................................13-14

1. Application Overview .......................................................15

2. Inputs and Outputs Conguration....................................15

3. Sequence of Operation....................................................16

3.1. Power Fail Restart.................................................16

3.2. Random Start Delay..............................................16

3.3. Compressor Fixed On Delay Time ........................16

3.4. Compressor Minimum On Delay ...........................16

3.5. Compressor Short Cycle Delay Time ....................16

3.6. Pump Sampling.....................................................16

3.7. Heating Cycle...................................................16-17

3.8. Cooling Cycle ........................................................17

3.9. Emergency Shutdown ...........................................17

3.10. Lockout Mode......................................................18

3.11. Entering Load Water Temperature (AI-1).............18

3.12. Leaving Load Water Temperature (AI-2) .............18

3.13. Entering Source Water Temp (AI-3) ....................19

3.14. Source Low Water Coil Temperature Limit (AI-4) .. 19

3.15. Load Low Water Coil Temperature Limit (AI-5) ...19

3.16. Entering Source Water Temp (AI-6) ....................19

3.17. Compressor Proving (BI-1)..................................19

3.18. Emergency Shutdown (BI-2) ...............................19

3.19. Low Pressure Switch (BI-3)................................19

3.20. Source Side Low Water Coil

Temperature Limit Select (BI-4)....................................19

3.21. Source Side Low Water Coil Temperature

Limit Selection (BI-5)....................................................19

3.22. Y1/System Enable Command (BI-7) ...................20

3.23. Source Flow Proving Switch (BI-8)......................20

3.24. Aqua-stat O/Heating-Cooling

Select Command (BI-9)................................................20

3.27. Load Flow Proving Switch (BI-12).......................21

4. Outputs............................................................................21

4.1. Reversing Valve (BO-1).........................................21

4.2. Compressor (BO-2)...............................................21

4.3. Reversing Valve (BO-3).........................................21

4.4. Secondary Unit Enable (BO-4)..............................21

4.5. Secondary Unit S-Plan Comfort Select

Enable (BO-5) ..............................................................21

4.6. Alarm Output (BO-6)..............................................21

4.7. Accessory Output 1/Source Pump

Control (BO-7)..............................................................22

4.8. Accessory Output 2/Load Pump

Control (BO-8)..............................................................22

Unit Startup..........................................................................23

ARI/ISO/BS EN Ratings ......................................................24

Capacity Data.................................................................25-40

Source Flow Rates (L/s)......................................................41

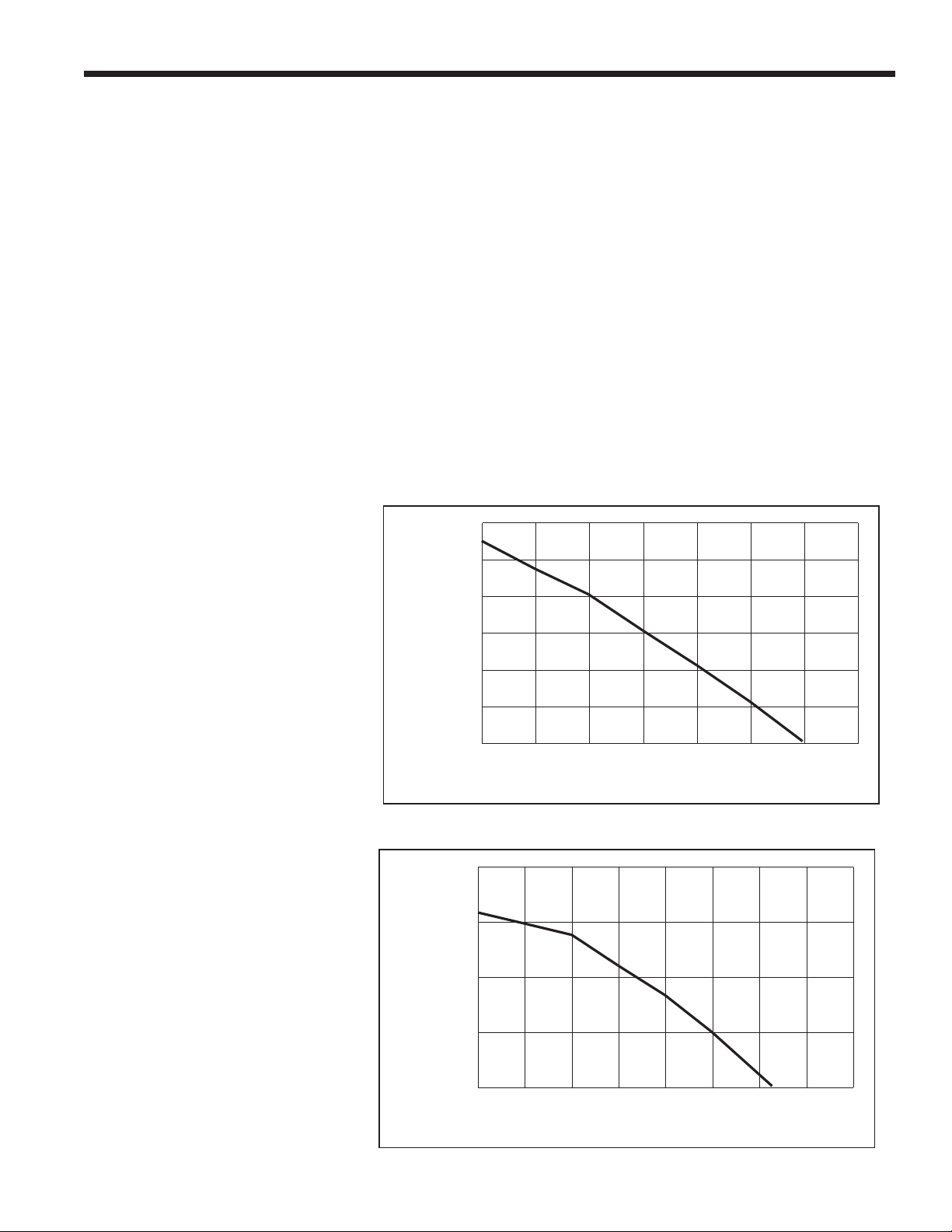

Pressure Drop (kPa)............................................................41

Troubleshooting...................................................................42

Preventive Maintenance......................................................43

Disposal/Recycling Section .................................................44