TABLE OF CONTENTS

GENERAL............................................................................................................................................. 1-1

afety First ...................................................................................................................................... 1-1

Model & erial Number Designations ............................................................................................. 1-2

Model & erial Number Label & Wiring Diagram Locations ........................................................... 1-3

pecifications .................................................................................................................................. 1-4

Whirlpool DryAire Drying Cabinet Warranty ................................................................................... 1-5

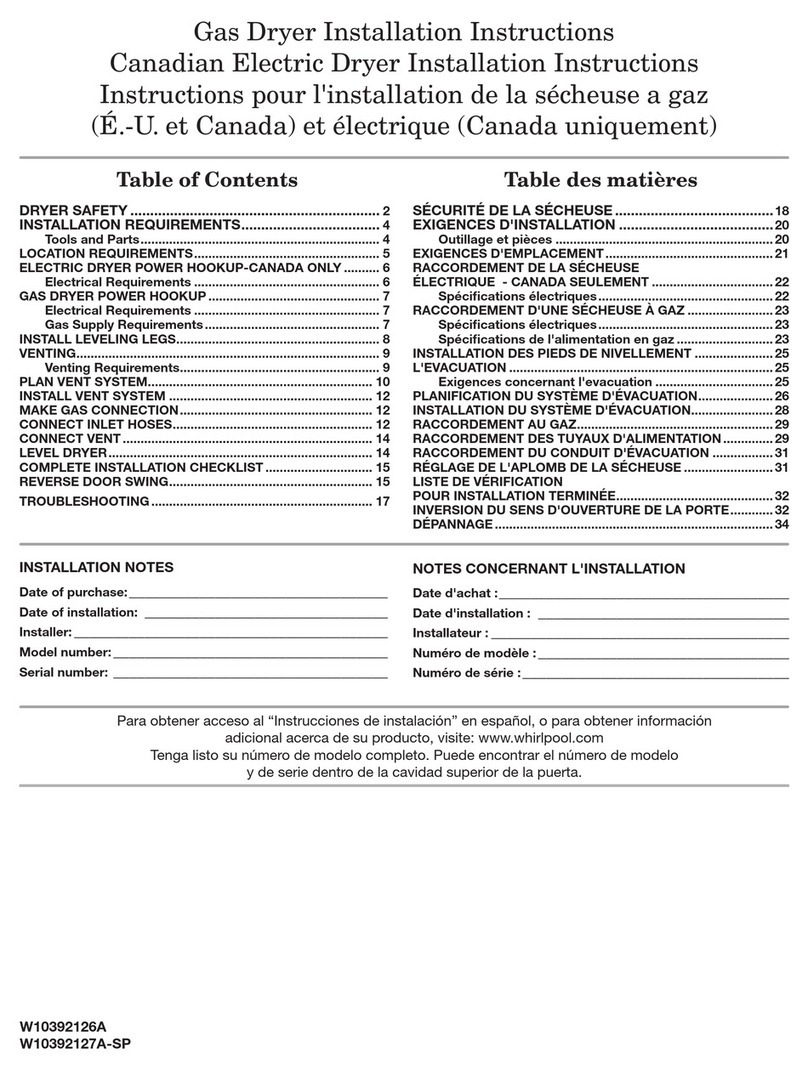

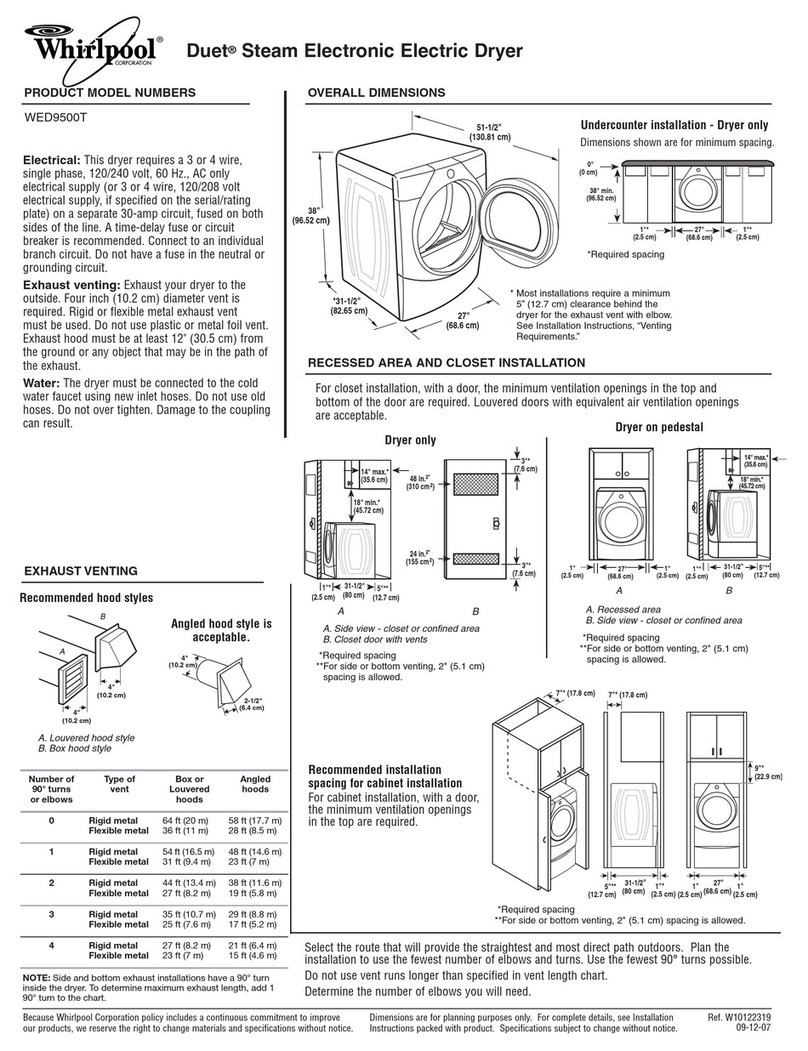

INSTALLATION INFORMATION ......................................................................................................... 2-1

Mounting The Cabinet ..................................................................................................................... 2-1

Changing The Door wing .............................................................................................................. 2-2

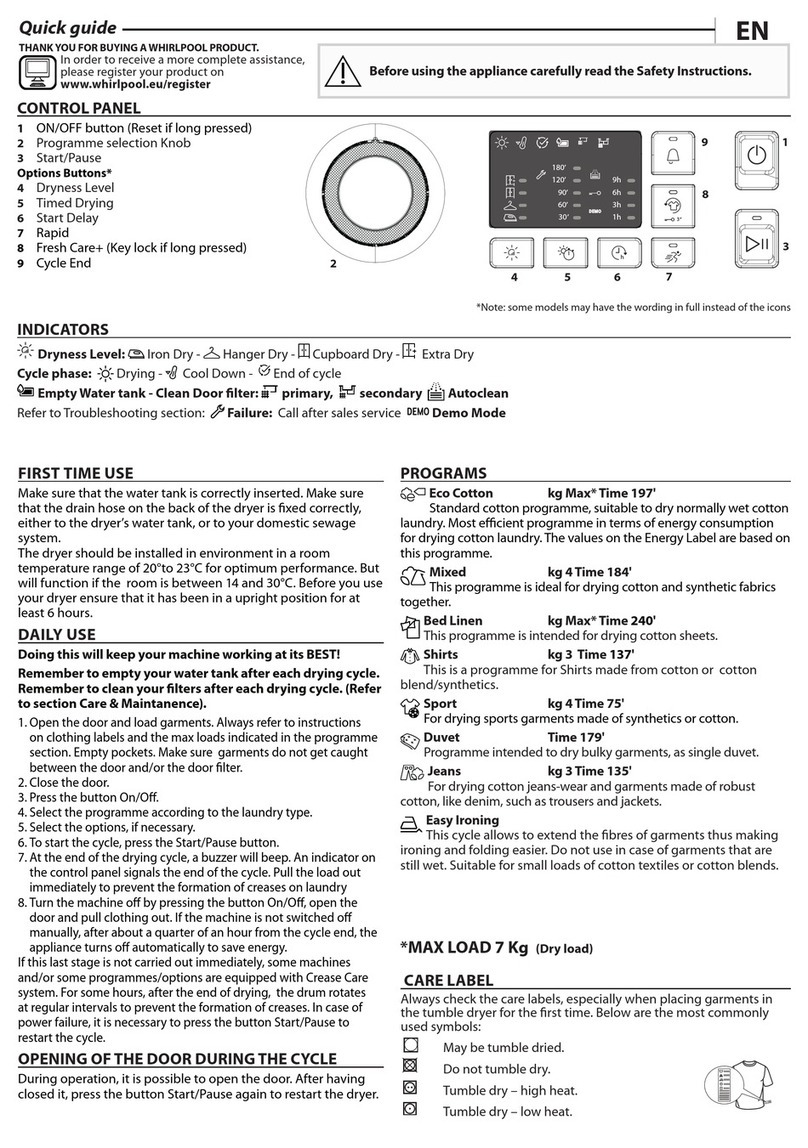

PRODUCT OPERATION ...................................................................................................................... 3-1

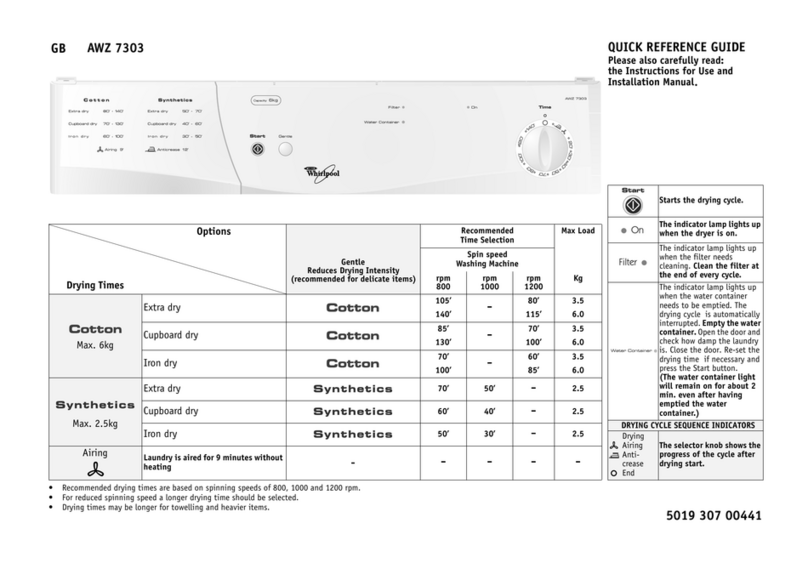

Drying Clothes................................................................................................................................. 3-1

Controls & witches ........................................................................................................................ 3-2

COMPONENT ACCESS ....................................................................................................................... 4-1

Component Locations ..................................................................................................................... 4-1

Removing The Component Panel ................................................................................................... 4-2

Removing The High Limit Thermostat And The Heater .................................................................. 4-3

Removing The Timer ...................................................................................................................... 4-4

Removing The Blower Assembly, The Thermostat & Temperature ensor ................................... 4-5

Removing The Relay ...................................................................................................................... 4-6

Removing The Push-To- tart & Door witches ............................................................................. 4-7

Removing The Component Panel-Mounted Terminal Block........................................................... 4-8

Removing The Power Cord And Cabinet-Mounted Terminal Block ............................................... 4-9

Removing The Cabinet Door ........................................................................................................ 4-10

COMPONENT TESTING ...................................................................................................................... 5-1

High Limit Thermostat ..................................................................................................................... 5-1

Heater ............................................................................................................................................. 5-1

Fan Motor ........................................................................................................................................ 5-2

Thermostat ...................................................................................................................................... 5-2

Timer ............................................................................................................................................... 5-3

Door & Push-To- tart (PT ) witches............................................................................................ 5-3

WIRING DIAGRAM .............................................................................................................................. 6-1

Page

iii