9401-130-001-EN · Version 17-01 · Minimat

Contents

1 Explanation of the User Information 4

1.1 Legends 4

1.1.1 Degrees of danger/symbols 4

1.1.2 Safety information and symbols 5

1.2 Type plate 6

1.3 Excerpt from the EU Declaration of Conformity 7

2 Product Description 8

2.1 Function/overview 8

2.2 Intended use 8

2.3 Reasonably foreseeable misuse 8

2.4 Liability 8

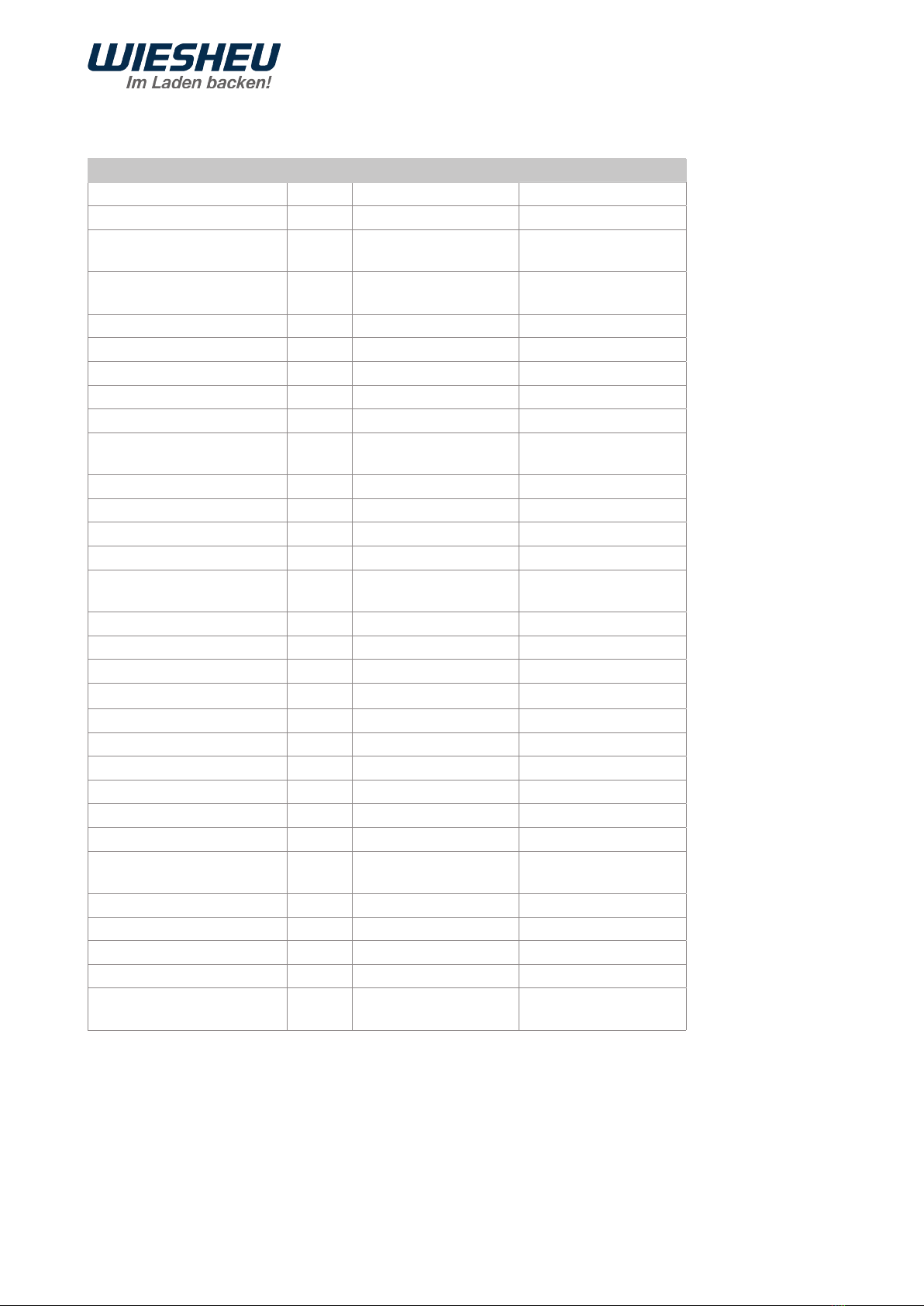

2.5 Technical Specications 9

2.5 Technical specications custom version 10

2.6 Risk of injury / residual risks 11

2.6.1 Obligation of the customer 11

2.6.2 Obligation of the sta 11

2.6.3 General risk of accidents 11

2.6.4 Danger of re/explosion 11

2.6.5 Danger from contact with electrics 12

2.6.6 Danger of burns 12

2.6.7 Water damage 12

2.6.8 Danger of non-ionising radiation 12

2.6.9 Risk of technical damage 13

3 Transportation and Setup 13

3.1 Transport 13

3.2 Unpacking 13

3.3 Installing / dismantling the appliance combination 14

3.4 Place of installation and surroundings 15

3.5 Place of installation and distances 15

3.5.1 Free space next to, above and below the appliance/combined appliance 15

3.5.2 Free space in front of and behind the appliance/combined appliance 16

3.5.3 Distances to sources of heat 16

3.5.4 Distances to safety equipment 16

3.5.5 Combined appliance with enclosure 17

3.5.6. Appliance ID 17

3.6 Connections on-site 18

3.6.1 Electrical connection 18

3.6.2 Plumbed-in water connection for the steaming unit 19

3.6.3 Exhaust air connection 20

3.7 Commissioning 20

3.7.1 Inspections to be carried out before commissioning 21

4 Operation 22

4.1 Switching the in-store baking oven on/o 22

4.2 Opening/closing the door 22

4.2.1 Opening/closing of “manual” Minimat oven door 22

4.2.2 Opening/closing of “electrical” Minimat oven door 22

4.2.3 Emergency unlocking if equipped with electrical door lock 23

4.3 Inserting/removing bakery products 23

4.4 Setting the baking parameters 24

4.5 Removing/installing the tray frames 24

4.6 Tank option 25

4.6.1. Removing/lling/inserting the water tank 25