© Wikora GmbH Page 5 As of November 2013

Errors excepted.

5 Installation

All pipes connecting to the tank should have removable connections (fitting/flange). Pipe thread seals with teflon are

to be avoided.

All tank connecting pipes are to be planned, constructed and tested according to the technical rules in force, as well as to the

corresponding norms and regulations in accordance with their application and supply medium.

In highly calcareous water areas, we recommend to foresee a decalcification possibility through stop valves with drain

possibility or t-piece with cold water inlet and hot water outlet of the DHW heat exchanger or a water softening device.

Appropriate filters should be used to prevent dirt or particles from entering the tanks. Moreover, the tank should be ensured

against pressure fluctuations and excess pressure through the installation of tested pressure reducing valves and safety

valves.

Sensors and thermostats necessary for temperature control must be securely and permanently positioned on the tank

(immersion sleeve and sensor rail).

The tank’s venting and draining facilities must have the appropriate dimensions and be correctly installed.

The installation company is responsible for the correct execution of work and for the safe and careful insulation of the pipes.

•When connecting to a solar plant, a temperature limiter is required and must be installed on site at the hot water outlet in

order to prevent scalding.

•The minimum rate of flow for the charge pump of the hot water supply amounts to 850 l heating water / h.

•On the heating water side, the minimum pressure loss in the coaxial corrugated tube amounts to 125 mbar.

•The necessary heating water pump (to be provided on site) must have the appropriate dimensions.

•A temperature limiter is required and must be installed on site at the hot water outlet in order to prevent scalding.

When installing a circulation pipe, the plug in the flange cover must be replaced by a circulation connection attachment (plastic

immersion pipe with double nipple R ¾”, Wikora part number 096 090).

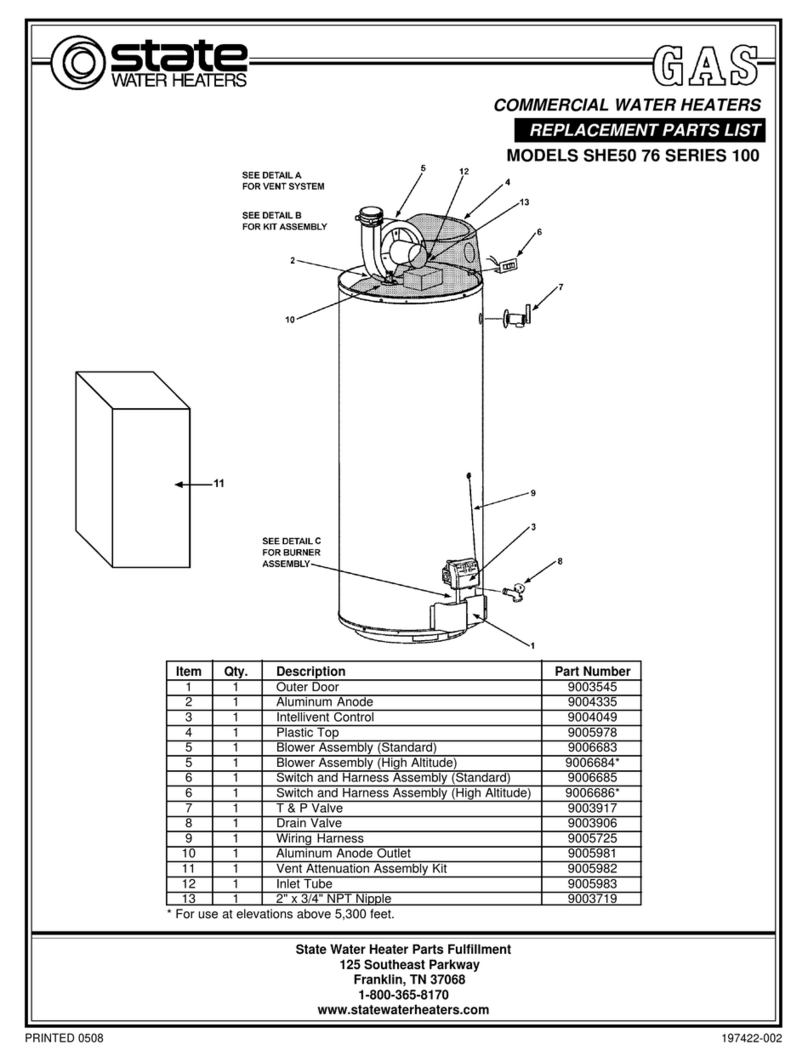

The thread diameter of the heating safety valve depends on the nominal capacity of the water space and the maximum heating

capacity of the heat generator. It can be determined as follows:

Reaction pressure Max. heating capacity of the heat generator

1,5 bar 36 kW 72 kW 144 kW 252 kW 433 kW 650 kW

2,0 bar 43 kW 86 kW 172 kW 302 kW 518 kW 778 kW

2,5 bar 50 kW 100 kW 200 kW 350 kW 600 kW 900 kW

3,0 bar 56 kW 112 kW 224 kW 395 kW 678 kW 1017 kW

Thread diameter (inch) 1/2 ¾ 1 5/4 6/4 2

lllustration 2 (Schematic drawing– example hydraulic system heating)

The size of the DHW safety valve is shown below:

Content of DHW space Min. valve size Max. heating performance

up to 200 l NW 15 (1/2“) 75 kW

above 200 to 1000 l NW 20 (3/4“) 150 kW