Wilcoxon PC420VP Series User manual

Wilcoxon Sensing Technologies

20511 Seneca Meadows Parkway, Germantown MD 20876, USA

Amphenol (Maryland), Inc d/b/a Wilcoxon Sensing Technologies

Tel: +1 (301) 330-8811

Tel: +1 800 WILCOXON

Fax: +1 (301) 330-8873

www.wilcoxon.com

78001 Rev B 09/17

PC420 series installation guide

4-20mA series transducers

Loop Powered Sensors (LPS®)

Caution: This guide should be read carefully before installation

78001 Rev B Page 2 of 8

Safety section

PC420-series vibrationtransducers can be safely installed when the instructions inthis manual are

carefully followed. This section summarizes the safety considerations. Reminders in the form

described below, will appear in the detailed instructions to assure operatorawareness of these safety

considerations. Qualifiedpersonnel should install the PC420-series vibration transducers only after

becoming thoroughly familiar with this manual.

WARNING: This symbol is used in the instruction manual where the safety of the operator

must be considered. The instruction manualshould be consulted and read carefully.

CAUTION: This symbol is used when caution is needed to prevent damage to equipment. It is used

where careful attention to certain procedures described in the instruction manual is needed. This

symbol is also used to emphasize procedures other than normal operating procedures.

Safety summary

1. The PC420-series vibration transducers covered bythis installationguide do not require any

special precautions, protective devices or equipment.

2. Because the PC420-series vibration transducers are designed to be mounted on rotating

industrial equipment, personnel involved with the installation of PC420-series vibration

transducers shouldbe familiar with all plant safetyrequirements before beginning installation.

3. The PC420-series vibration transducers are hermetically sealed.

4. There are no user serviceable parts within the PC420-series vibration transducers.

5. Use commonsense and avoid haste during the installation of the PC420-seriesvibration

transducers!

78001 Rev B Page 3 of 8

Contents

1.0 Introduction………………………………………………………… 4

2.0 Applicable models………………………………………………… 4

3.0 Mounting……………………………………………………………. 5

3.1 Threaded stud…………………………………………………… 5

3.2 Cementing pad.......................................................................... 5

4.0 Cabling……………………………………………………………… 6

5.0 Technical assistance…………………………………………...... 8

5.1 Technical assistance…………………………………………… 8

5.2 Customer service……………………………………………….. 8

78001 Rev B Page 4 of 8

1.0 Introduction

This guide is designed toassist the user in the physical installation and wiring of theWilcoxon

Sensing Technologies PC420 series of vibration transducers. It is presumed that the user has already

selected the mounting location and model of PC420-series transducer to be used. Assistancefor the

selection, location, and use of these transducers is contained in the “Application Guide for PC420-

series LPS® Transducers” available from Wilcoxon Sensing Technologies.

2.0 Applicable models

This installation guide is intended for use with the PC420-series units with either velocity output

(PC420Vx-yy) or acceleration output (PC420Ax-yy) as well as those with dynamic output (PC420xx-

yy-DA or PC420xx-yy-DV).

PC420Vx-yy and PC420Ax-yy

The velocity or acceleration units are two-wire devices. The model number designations have a root,

PC420V or PC420A, designating the basic 4-20mAoutput as either velocity or acceleration. The

PC420V-series are velocity 4-20mA output. The PC420A-series are acceleration 4-20mA output. The

x-yy portion of the model number designates the type of signal processing and the full-scale range.

The signal types are VR or AR for “root-mean square (rms)” signal output and VP or AP for “peak”

signal output. The table below summarizes the models and full-scale ranges available.

Table 1 –PC420 model numbers for 2 wire output

PC420VR-yy

4-20mA velocity, rms

PC420VP-yy

4-20mA velocity, peak

PC420AR-yy

4-20mA acceleration, rms

PC420AP-yy

4-20mA acceleration, peak

PC420Vx-yy-Dzand PC420Ax-yy-Dz

The dualoutput units areavailable with both the acceleration and velocity 4-20mA signal outputs as

listed above and a dynamic signaloutput. The dynamic signal can be either velocityor acceleration,

-DV or-DA. This allows the user to select both the type of 4-20mA loop output signaland the type of

dynamic signal desired. The acceleration dynamic output (100 mV/g) and the velocity dynamic signal

is 100 mV/ips.

Table 2 –PC420 model numbers for dynamic signal output

PC420xx-yy-DA

Dynamic acceleration output, 100 mV/g

PC420xx-yy-DV

Dynamic velocity output, 100 mV/ips

-yy full scale

Velocity

Acceleration

-05

0.5 ips

5 g

-10

1.0 ips

10 g

-20

2.0 ips

20 g

-30

3.0 ips

N/A

-50

5.0 ips

N/A

78001 Rev B Page 5 of 8

3.0 Mounting

When using vibration transducers to measure vibration, the transducer must have direct contact

with the machine surface. Thetransducer should bemounted in a location thatminimizes the

vibration transmission route throughthe machine. Avoid mounting the transducer onthin sections

or vibration free areas (antinodes).

Direct stud mounting, epoxy and cementing pads are usedfor permanent installations.The

transducer can be directly mounted by tapping a hole into the structure and attaching the transducer

with a threaded stud. Cementing pads can be epoxied in place of the tapped hole; the transducer is

then mountedto the pad. In some cases, thetransducer can be mounted directly to the machine

using epoxy.

Cementing pads approach the capabilities of stud mounts when usedproperly. Thefollowing

are recommended permanent mounting procedures. Alternative procedures should be

evaluated with respect tofrequency response, grounding, and installationrequirements.

Adhesive selection is critical for long-term reliability; please consultWilcoxon Sensing

Technologies before other procedures and materials are used.

3.1 Threaded Stud

Stud mounting requires a tapped hole drilled directly into the structure. A

threaded stud provides electrical andmechanical connection between the

transducer and machine. The transducer requires a flat spot-faced surface

with a perpendicular tapped hole. The spot face must be 1.1 times larger

than the diameter of the transducer housing to ensure flush mounting. Burrs

between the transducer and the machinemust be eliminated. The centerline of

the tapped hole should be perpendicular within 1° of the mounting surface to

ensure nogaps are present between the base of the transducer and the

structure. The tap drill and spot face can be machined in one step using the

Wilcoxon ST101 Spot-Face tool. The ST101 will face the surfaceand drill the tap

hole perpendicular to the face in one operation. The drill supplied with the ST101

is sized for a 1/4-28 tap. Additional guidance onmounting procedures and techniques can be

obtainedfrom Wilcoxon Sensing Technologies Technical note 21, Mounting considerations. It is

available for download from theWilcoxon web site at www.wilcoxon.com.

The PC420-series transducers should be torqued to a value between 26- 30 inch-pounds.

3.2 Cementing pad

Cementing pads eliminate tapping into the structure, but provide high frequency

capability approaching stud mounts. The PC420-series transducers should be

mounted using a Wilcoxon SF8 cementing pad. The flat side is bondedto the

machine with an appropriate adhesive. The opposite side contains a 1/4-28 stud for mounting the

transmitter. Additional guidance on cementing pad mounting procedures can be obtained from

Wilcoxon’s Technical note 21, Mounting Considerations. It is available for download from the

Wilcoxon Sensing Technologies web siteat www.wilcoxon.com.

The PC420-series transducers should be torqued to 26 - 30 inch-pounds.

SF6 stud

SF8 cementing pad

ST 101

Surface preparation

78001 Rev B Page 6 of 8

J9F cable

R6Q connector

4.0 Cabling

Wilcoxon Sensing Technologies has cabling available with connectors alreadyinstalled for use

with the PC420-series vibration transducers. These cables are two-conductor, shielded, twisted

pair wire for the 4-20 mA loop output and three-conductor, shielded, twisted wire for the dual

output transducers. Isolated connectors are recommended for use with PC420-series

transducers to eliminate the possibility of ground loops when wiring to 4-20 mA loop inputs. The

cables listed below all use isolated connections for the shield at the transducer end of the cable

so that the shield will not be grounded at the transducer.

Stock cable model numbers for use with the PC420-series transducers are:

Table 3: Standard cable lengths for stock cables

Length

Cable

Use with

Feature

5 m / 16 ft

R6W-0-J9T2A-16

2-wire PC420

IP67 connector, Teflon, braided shield

R6W-0-J9T2A-16

2-wire PC420

IP67 connector, Teflon, braided shield

R6W-0-J9F-16

2-wire PC420

IP67 connector, Teflon, braided shield

R6W-0-J9F-16

2-wire PC420

IP67 connector, Teflon, braided shield

R6GQI-0-J9T3A-16

Dual output PC420

IP68 connector, Teflon, braided shield

Length

Cable

Use with

Feature

10 m / 32 ft

R6QI-0-J9T2A-32

2-wire PC420

IP68 connector, Teflon, braided shield

R6W-0-J9F-32

2-wire PC420

IP67 connector, Teflon, foil shield

R6QI-0-J9F-32

2-wire PC420

IP68 connector, Teflon, foil shield

R6GQI-0-J9T3A-32

Dual output PC420

IP68 connector, Teflon, foil shield

Cables can be manufactured in other lengthsfor an additional charge.

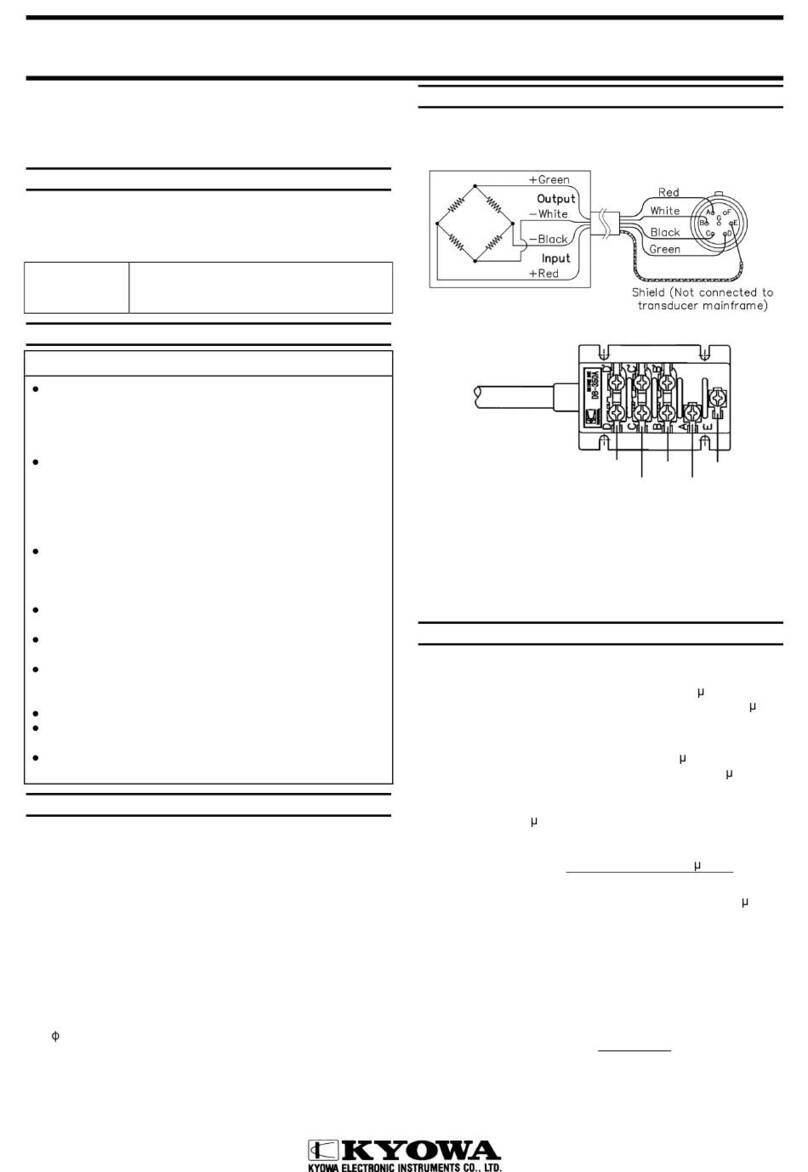

Connection

The PC420 Series Transducers are loop powered devices. There is no additional

signal conditioning equipment required for the transducers to function. The tables

below show the cable conductor wire colors for the J9T2A, J9T3A and J9F cable

assemblies listed in the previous section. The shield of the cable does not make electrical

contact with thecase of the PC420 seriestransducer. For other cable configurations,

contact your Customer sales representative at 1800WILCOXON.

Table 4: Output pin and cable conductor color designations fortwo wire PC420 series transducers

PC420xx-yy pin

Function

J9T2A

J9F

A

Loop power +

White

Red

B

Loop return -

Black

Black

Table 5: Output pin and cable conductor color designations for dual output PC420 series transducers

PC420xx-yy-Dz pin

Function

J9T3A

A

Loop power +

Red

B

Loop return/dynamic common -

Black

C

Dynamic signal output

White

J9T2A cable

R6W connector

78001 Rev B Page 7 of 8

Figure 1: Typical two wire installation wiring

CAUTION: The common for the dynamic output is also the return signal for the 4-20mA loop wiring.

Connecting this pin to ‘ground’ will usually short out the 4-20mAloop return resulting in a lossof the

4-20mA signal. The dynamic output is designed to be used by portable data collectors where no

direct connection to ground exists. It can also be used by on-line systems when their signal input is

galvanicallyisolated from ground.

Figure 1: Typical dual output installation wiring

CAUTION: The common forthe dynamic output is also the return signal for the 4-20mA loop wiring.

Connecting this pin to ‘ground’ will usually short out the 4-20mAloop return resulting in a lossof the

4-20mA signal. The dynamic output is designed to be used by portable data collectors where no

direct connection to ground exists. It can also be used by on-line systems when their signal input is

galvanicallyisolated from ground.

No

connection

at sensor

78001 Rev B Page 8 of 8

5.0 Technical assistance

5.1 Technical assistance

For technical assistance, please contactWilcoxon Sensing Technologies at 301-330-8811 or

email info@wilcoxon.com.

5.2 Customer service

For all customer service inquiries, please call 301-330-8811 or email info@wilcoxon.com.

This manual suits for next models

3

Table of contents

Popular Transducer manuals by other brands

HBM

HBM TB1A Mounting instructions

Camille Bauer

Camille Bauer SINEAX U553 operating instructions

Daiichi Electronics

Daiichi Electronics FAETT2-92A-33 instruction manual

Veris Industries

Veris Industries PH Series installation instructions

KYOWA

KYOWA BER-A-15S instruction manual

Lumel

Lumel P30H User Manual & Quick Start

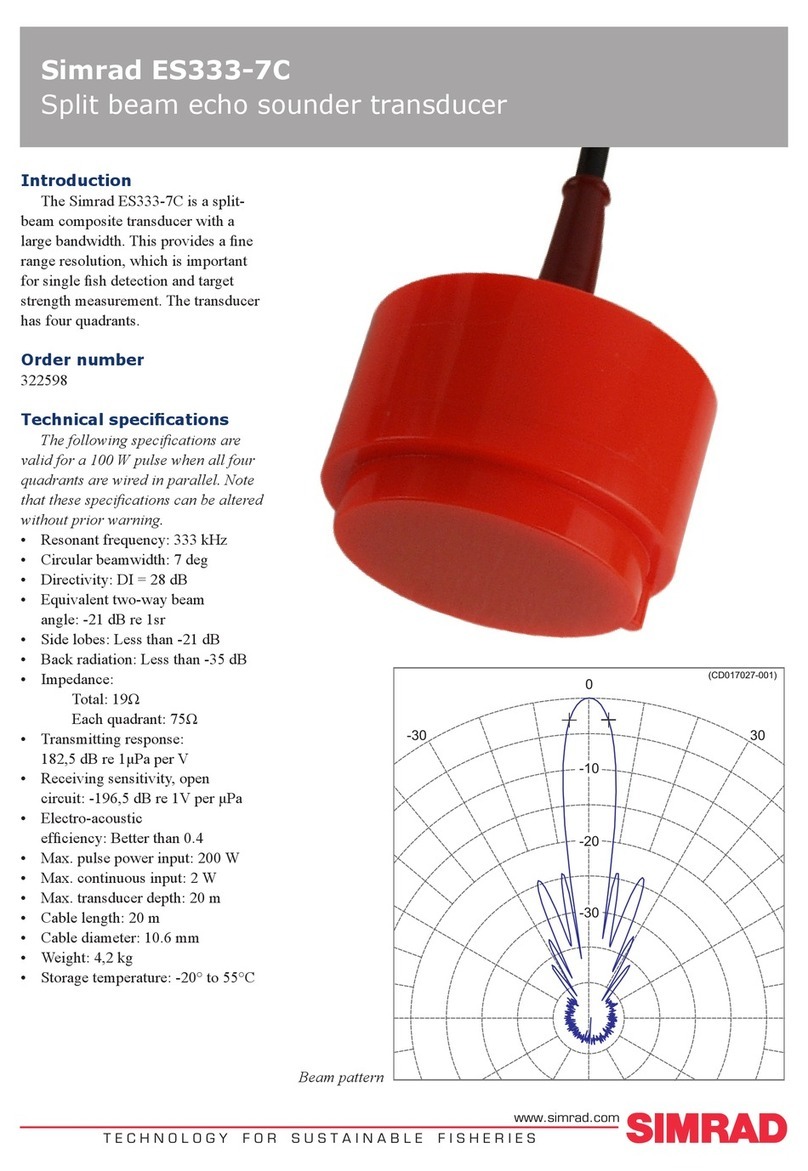

Simrad

Simrad ES333-7C - REV A datasheet

Airmar

Airmar Ultrasonic TRIDUCER UDST800 Owner's guide and installation instructions

Siedle

Siedle Novotechnik TH1 CANopen user manual

Camille Bauer

Camille Bauer Sineax p 530 operation instruction

Aerospace Logic

Aerospace Logic FF200X Series Operation guide

Knick

Knick VariTrans P 41000 TRMS user manual