INTRODUCTION

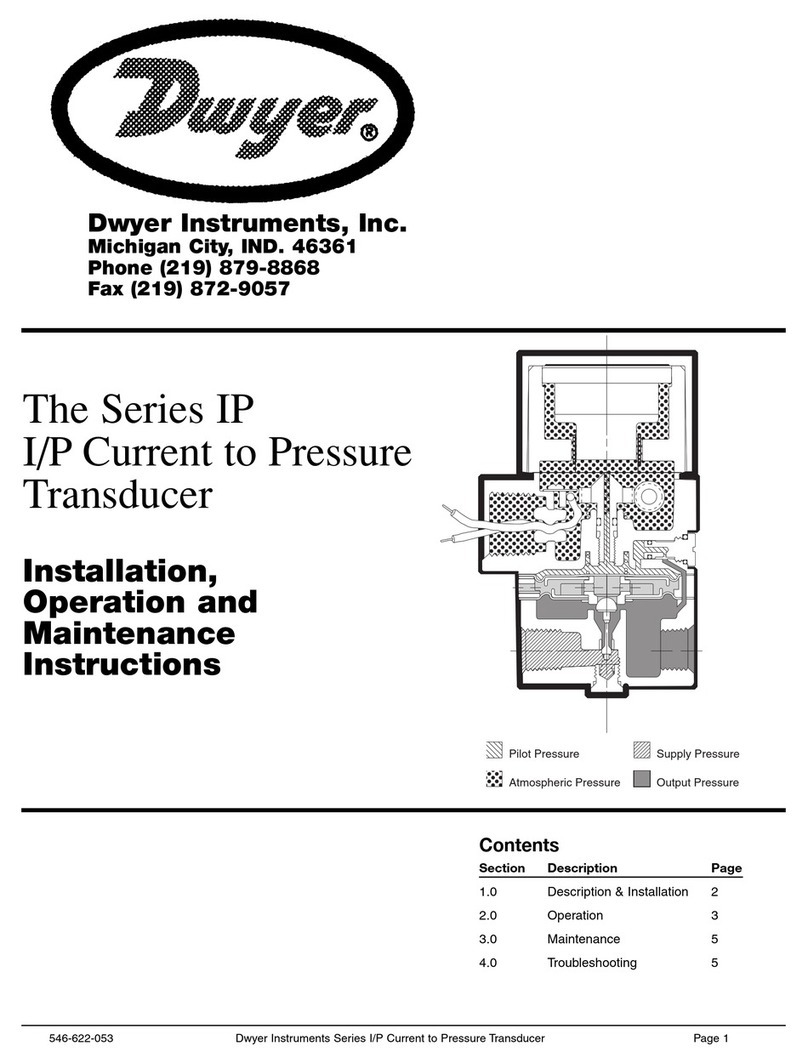

The Dwyer Series 2200 Current to Pressure Transducer combines low cost, accuracy, and minimal air consumption with field

proven technology. The design features a rugged, compact housing with FM approved Intrinsically Safe operation when used

with a barrier. This transducer utilizes a virtually weightless membrane that is electro-magnetically positioned over the air flow

consuming minimal air and electrical energy while providing an accurate, precise output pressure signal. This low-mass mem-

brane yields an output that is virtually unaffected by shock, vibration or mounting position. By employing an internal feedback

network, the I/P responds quickly to step input changes, and by balancing air supply and exhaust provides control stability,

while delivering accuracies of ±0.15% or ±0.25%. The pneumatic control signal is enhanced by an integral volume booster. The

unit features easy access to zero and span adjustments along with field selectable direct, reverse and split range operation.

SECTION DESCRIPTION PAGE SECTION DESCRIPTION PAGE

1.0 . . . . . INSTALLATION . . . . . . . . . . . . . . . . . 3 3.0 . . . . . . . . .MAINTENANCE AND REPAIR . . . . . . .8

2.0 . . . . . OPERATION . . . . . . . . . . . . . . . . . . . 6 4.0 . . . . . . . . .TROUBLE SHOOTING GUIDE . . . . . . .9

DANGER, WARNING, CAUTION and NOTE Statements:

• Refers to conditions or hazards which could result in serious personal injury or death.

• Refers to conditions or hazards which could result in personal injury.

• Refers to conditions or hazards which could result in equipment or property damage.

• Alerts you to facts or special instructions.

All DANGER, WARNING, AND CAUTION NOTICES MUST BE COMPLIED WITH IN FULL

SPECIFICATIONS

DANGER

WARNING

CAUTION

NOTE

Input . . . . . . . . . . . . . . . . .

Output . . . . . . . . . . . . . . .

Accuracy . . . . . . . . . . . . .

Repeatability . . . . . . . . . .

Deadband . . . . . . . . . . . .

Stability/Reproducibility .

Position Effect . . . . . . . . .

Vibration Effect . . . . . . . .

Frequency Response . . .

Loop Load . . . . . . . . . . . .

Operating Current . . . . . .

Supply Pressure . . . . . . . .

Supply Pressure Effect . .

Output Capacity . . . . . . .

Air Consumption . . . . . . .

Operating Temperature . .

Temperature Effect . . . . .

RFI-EMI Effect . . . . . . . . .

Operational Modes . . . . .

Failure Mode . . . . . . . . . .

Enclosure . . . . . . . . . . . . .

Electrical Safety . . . . . . . .

Weight . . . . . . . . . . . . . . .

4-20mA

6-30 or 3-15 psig (41-207 or 20-103 kPa)

±0.15% of Span (3-15 psig, 41-207 kPa) & ±0.25% of Span (6-30 psig, 20-103 kPa)

±0.05% of Span

0.02% of Span

0.5% of Span / 6 Months

Not Measurable

<0.25% from 1-200Hz/1g

-3db at 5 Hz (per ISA-S26.4.3.1 Configuration A)

3.8Vdc +5 ohms (195 ohm load at 20mA)

3.7mA min. 200mA max. continuous at 120°F; Half cycle 70 amp 1/120 sec. at 68°F

20 (±2) psig for 3-15 psig output, and 35 (±2) psig for 6-30 psig output.

Not measurable within the recommended supply pressure range

4.0 SCFM (Supply and Exhaust characteristics are balanced to within ±10%)

0.04 SCFM Steady State Average (0.06 SCFM Maximum)

-40° to 150°F (-40° to 66°C)

±0.02% / °F of Span (Range of 0°F to 150°F), or ±0.04% / °F of Span (Range of -40°F to 150°F)

Per SAMA PMC 33.1 standard (b), (c) 20 to 1000MHz, Class 3 effect on zero & span less than 1%. Also

tested and found to comply with BS EN50081-2: 1993 Generic Emissions, Residential, Commercial and

Light Industrial and BS EN50082-2: 1995 Generic Immunity, Residential, Commercial and Light Industrial.

Direct, Reverse, and/or Split-Range (field-selectable, no additional parts needed)

Transducer Always Fails In The Mechanically Direct Mode Regardless Of Mode Selection. Example: Unit

with a 3-15 psi output will fail to 3 psi (or less) with the loss of Input Signal (mA).

Internally purged NEMA 4X. Cast Aluminum with powder coat epoxy

Factory Mutual, CSA and Sira/CENELEC Approved Intrinsically Safe. See Sections 1.5, 1.6 & 1.7.

2.5 lbs (1.13 kg)

Bulletin-E-32 7/15/05 3:03 PM Page 2