10 REV B

60706-231

C. Remove the oil lter and dispose of it properly.

D. Before you install the new oil lter, clean the lter mounting base

and coat the seal of the new oil lter will clean engine oil.

E. Install the oil lter by hand until the gasket contacts the oil lter

adapter, then tighten the oil lter 1/2 to 3/4 turns.

F. Replace oil drain bolt making sure the sealing washer is in place.

G. Remover the oil lter plug and rell with new oil. Make sure to use

the proper grade oil based on your operating temperature.

NOTE: This engine requires 78 to 80 ounces (2.4 to 2.5 quarts) of oil if

it is completely drained. Use caution when relling the engine as some

residual oil may have remained in the engine. Always use the dipstick

when lling the engine with oil to prevent overlling.

H. Replace lter plug.

I. Start the engine and warm it up.

J . After warming up the engine, recheck the oil level and rell as

necessary to bring it to the proper level.

DUAL ELEMENT AIR FILTER

Clean and/or replace the foam pre-cleaner and the air lter annually or

every 100 hours. Service more often under dusty conditions.

WARNING: EQUIPMENT DAMAGE

Never start or run the engine with the air lter removed.

A. Loosen snaps (A) and

remove cover (B).

B. Remove the nut (D) and the

retainer (E).

C. Remove the air lter (F).

D. Remove the pre-cleaner (G)

from the air lter.

E. To loosen debris, gently tap the

air lter on a hard surface. If the

air lter is excessively dirty

replace with a new lter.

You can use pressurized air

(not to exceed 30 psi)

to clean the lter. Always blow the compressed air from inside to

the outside.

F. Wash the pre-cleaner in liquid detergent and water. Then allow it

to thoroughly air dry. DO NOT oil the pre-cleaner.

G. Install the pre-cleaner to the air lter.

H. Install the air lter and secure the retainer and nut.

I. Install and secure the cover.

SPARK PLUG

Replace annually or every 300 hours of operation. Always replace with

the same spark plug that came in the engine and check gap before

installing. Spark plug gap is 0.030”. Poor spark will also occur if spark

plug wire does not t rmly on spark plug. If this happens, reform the

terminal to t rmly on spark plug tip.

11

3110-00 60706-239

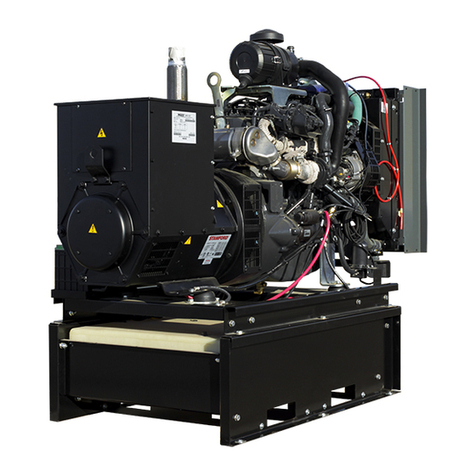

ENGINE CARE

If major engine service or repair is required, contact

an authorized engine service center. The manufac-

turer of these engines has established an excellent

world-wide engine service organization. Engine ser-

vice is very likely available from a nearby authorized

dealer or distributor. Check the yellow pages of your

local telephone directory under “Engines-Gasoline”

for the closest engine repair center or ask the dealer

from whom you purchased the power plant.

1. Change the oil after the first 5 hours of operation

and yearly or 100 hours thereafter under normal op-

erating conditions. Change engine oil every 50 hours

of operation if the engine is operated under heavy

load, or in high ambient temperatures.

a. Start the engine and warm it up, stop the engine

and remove the spark plug wire to prevent it

from accidently being started.

b. Remove oil drain plug at base of the engine

(Ref “B”) and drain the oil into an approved

container.

c. Remove the oil filter (Ref “C”) and dispose of it

properly.

d. Before you install the new oil filter, lightly lubri-

cate the oil filter gasket with fresh clean oil.

e. Install the oil filter by hand until the gasket

contacts the oil filter adapter, then tighten the oil

filter 1/2 to 3/4 turns.

f. Replace oil drain plug.

g. Remove oil filler plug and refill with new oil.

Refer to the table on page 5 for the proper

grade of oil based on your operating

temperature.

NOTE: This engine requires 78 to 80 ounces of oil

if it is completely drained. Use caution when refilling

the engine as some residual oil may have remained

in the engine. Always use the dipstick when filling

the engine with oil to prevent overfilling.

h. Replace filler plug.

I. Start the engine and warm it up.

J. After warming up the engine, recheck the oil

level and refill as necessary to bring it to the

proper level. See page 5 for proper oil level.

2. Checking the Oil Level: The oil level must al-

ways be checked before the engine is started. Take

care to remove any dirt or debris from around the

oil fill plug before removing. Be sure the oil level is

maintained. Fill to the “FULL” mark on the dipstick.

3. Dual Element Air Filter: Clean and/or replace

foam pre-cleaner and air filter annually or every 100

hours. Service more often under dusty conditions.

WARNING: EQUIPMENT DAMAGE

Never start or run the engine with the air filter re-

moved

a. Loosen snaps (Ref “A”) and remove cover.

Ref “B”

Maintenance Chart

First 5 Hours

xChange oil

Every 8 Hours or Daily

xCheck engine oil level

xClean area around muffler and controls

Every 100 Hours or Annually

xClean or change air filter *

xClean pre-cleaner (if equipped) *

xChange engine oil and filter

xReplace spark plug

xCheck muffler and spark arrester

Every 250 Hours or Annually

xCheck valve clearance. Adjust if necessary.

Every 400 Hours or Annually

xChange air filter

xReplace fuel filter

xClean air cooling system *

xClean oil cooler fins *

*In dusty conditions or when airborne debris is present, clean more often.

A

B

F

E

D

G

GENERATOR CARE

Proper care and maintenance of the generator is necessary to ensure a

long trouble free life.

EXERCISING THE GENERATOR

The generator should be operated every three to four weeks. It should

be operated for a period of time sufcient to warm the unit up and to

dry out any moisture that has accumulated in the windings. If left, this

moisture can cause corrosion in the winding. Frequent operation of the

engine-generator set will also ensure that the set is operating properly

should it be needed in an emergency.

GENERATOR MAINTENANCE

Any major generator service, including the installation or replacement

of parts, should be performed only by a qualied electrical service

technician. USE ONLY FACTORY APPROVED REPAIR PARTS.

A. Bearing - The bearing used in these generators is a heavy duty,

double sealed ball bearing. They require no maintenance or

lubrication.

B. Receptacles - Quality receptacles have been utilized. If a

receptacle should become cracked or otherwise damaged,

replace it. Using damaged or cracked receptacles can be both

dangerous to the operator and destructive to the equipment.

CLEANING

Remove dirt and debris with a cloth or brush. DO NOT use high

pressure spray to clean either the engine or the generator. The high

pressure spray could contaminate the fuel system and the generator

components.

1. Keep the air inlet screen on both the engine and generator free of

any dirt or debris to ensure proper cooling. At least yearly, remove

the blower housing on the engine and clean the chaff and dirt out of

the engine cooling ns and y wheel. Clean more often if necessary.

Failure to keep these areas clean may cause overheating and

permanent damage to the unit.

2. Periodically clean mufer area to remove all grass, dirt, and

combustible debris to prevent a re.

3. On engine mufers equipped with spark arresters, the spark arrester

must be removed every 50 hours for cleaning and inspection. Replace

if damaged.

CARBON CANISTER

Designed to collect, store, and dispose of fuel vapors created in the

fuel tank/fuel system. The canister should last the life of the unit as long

as it stays dry.