Customer Care | 800.234.5286

| +1.502.495.5400 |

winstonfoodservice.com

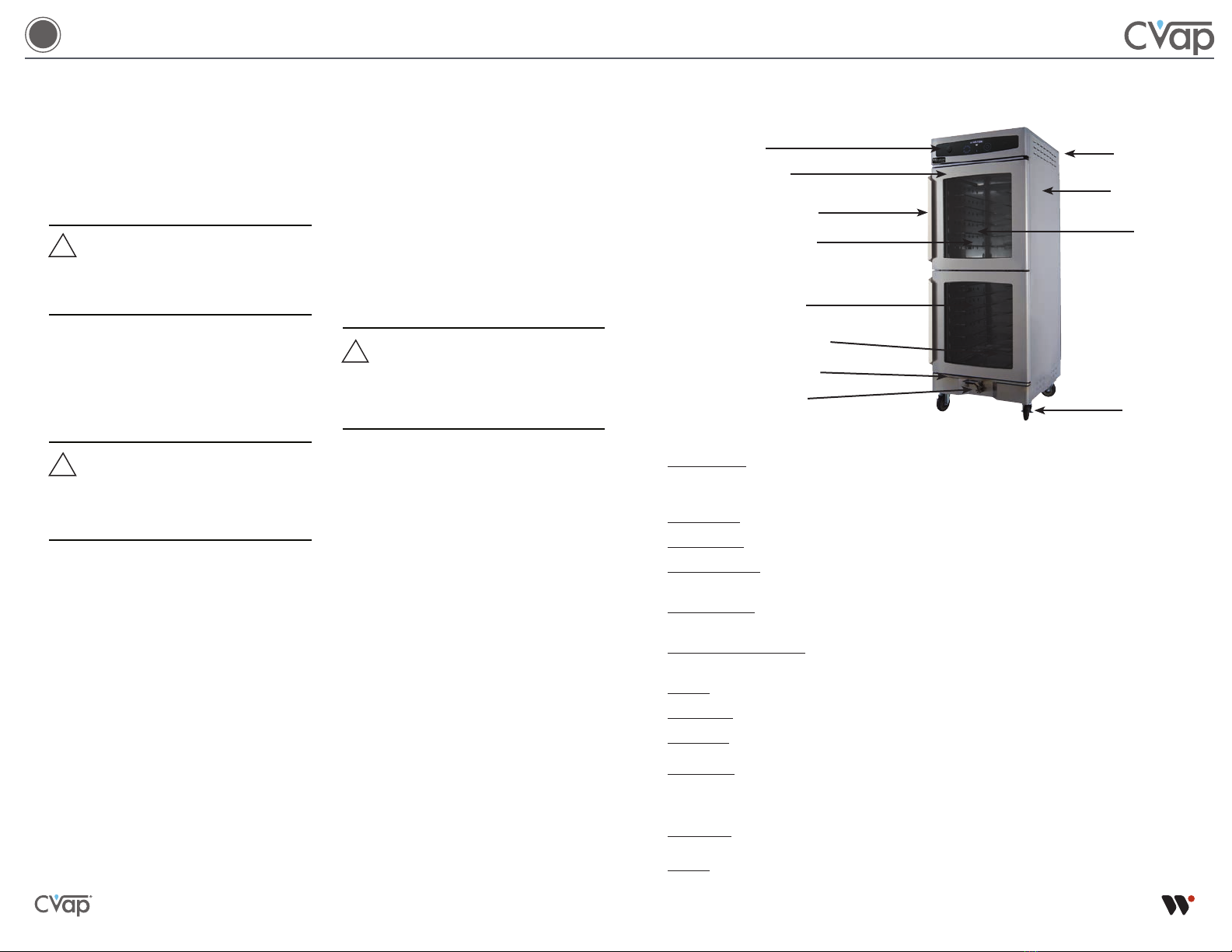

cook & hold - class series 3

2

Warnings

MISUSE AND OTHER

!WARNING:WARNING:

Contamination Hazard

Can cause serious illness or damage to

equipment >> Clean equipment daily to

avoid potential contamination hazard.

Ensure safe operation by cleaning

equipment daily. Failure to do so can allow

harmful deposits to develop, increasing

the potential for food contamination and

endangering your customers.

!DANGER:DANGER: Electrical Hazard

and Burn Hazard

Can cause serious injury or death >>

Do not attempt to service this equipment

unless you are a licensed electrician or

trained servicer.

This equipment uses high voltage electrical

systems, high temperature heating systems,

and hot water vapor. If used improperly, any

of these hazards are capable of causing

serious injury or death. To avoid the

potential for an accident, please have

equipment serviced only by trained

servicers. Please make this page available to

the servicer.

!CAUTION:CAUTION: High Temperature

and Grease Hazard

Can cause damage to equipment >>

Avoid placing equipment near high heat or

in grease-laden atmosphere.

Warranty & Terms and

Conditions of Sale

Limited one-year warranty (excluding

gaskets, lamps, hoses, power cords, glass

panels, fryer baskets, batteries, and

evaporators). Warranty disclaimer for failure

to clean.

WINSTON EXPRESSLY DISCLAIMS ALL OTHER

WARRANTIES, EITHER EXPRESS OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE AND

ANY IMPLIED WARRANTY OF

MERCHANTABILITY.

For complete details on warranty

and terms & conditions of sale,

go to: https:// bit.ly/2Qzwi6G

Both the Warranty and Terms

and Conditions of Sale are integral

to this document.

!WARNING:WARNING: Safety Hazard,

Intended Use

Can cause serious illness or damage to equipment

>> Supervise untrained, young, or handicapped

persons.

1. This equipment is not intended for use by

persons (including children) with reduced physical,

sensory, or mental capabilities, or lack of

experience and knowledge, unless they have been

given supervision or instruction concerning use of

the equipment by a person responsible for their

safety.

2. Children should be supervised to ensure that

they do not play with the equipment.

3. This equipment is intended to be used for

commercial applications, for example in kitchens of

restaurants, canteens, hospitals and in commercial

enterprises such as bakeries, butcheries, etc., but

not for continuous mass production of food.

!CAUTION:CAUTION: High Temperature

Hazard

Can cause damage to equipment >>

Fill evaporator with water prior to turning power

on, and do not allow evaporator to

run dry.

MAKE CERTAIN EVAPORATOR HAS AN

ADEQUATE SUPPLY OF WATER PRIOR TO

TURNING ON POWER SWITCH. WATER LEVEL

SHOULD BE APPROXIMATELY AT FILL LINE.

KEEP DOOR(S) CLOSED WHEN NOT IN USE. If food

temperature becomes too low during serving

period, increase VAPOR TEMP setting by 10-20°F

(11-17°C) to maintain desired food temperature.

!WARNING:WARNING: Burn Hazard

To avoid scalding, do not use loaded

containers with liquids or cooking goods

which becomes uid by heating in higher

levels than those which can be easily

observed.

!WARNING:WARNING: Burn Hazard

When opening the door of the cooking

compartment hot steam can come out.

!DANGER:DANGER: Electrical Hazard

If supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualified persons in order

to avoid a hazard.