489007105

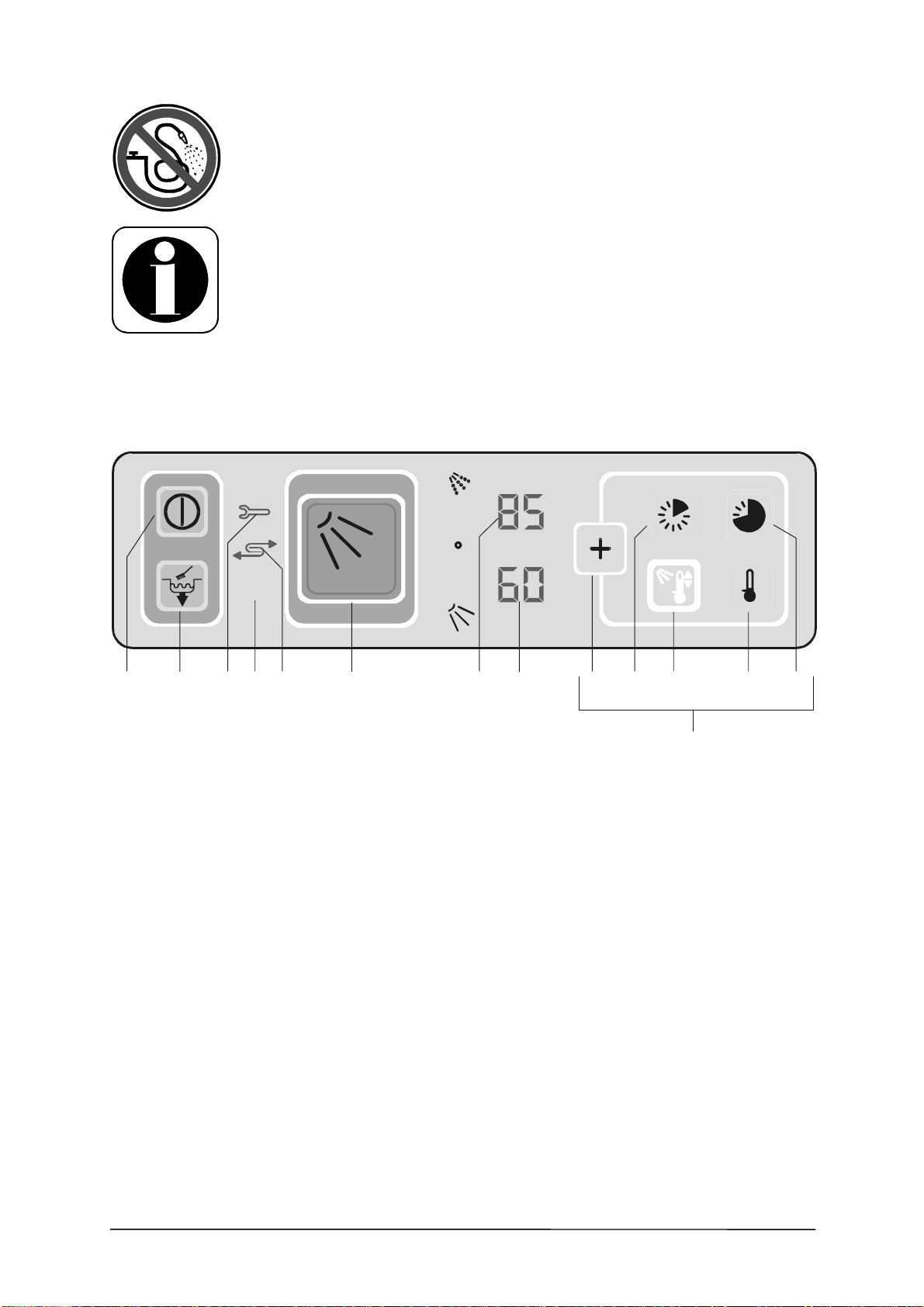

)XQFWLRQVRIWKHXWHQVLOZDVKHU

After the machine is switched on, the boiler and tank are filled and heated up to operating temperature.

The programme button (6) is lit red during the heating up phase.

As soon as the pre-set target temperatures (tank: approx. 60°C, boiler : approx. 85°C) have been

reached, the machine is ready for operation. The programme button (6) is now lit green.

The machine is operated with fully automatic programmes consisting of the program steps

washing, dripping off and rinsing.

The rinse additive is dosed by a built-in dosing device. With GS 660, the container for the rinse additive

can be stored inside of the machine. With the other machines it is stored separately.

Detergent must be added by hand (in the form of powder) or by means of a built-in or external dosing

pump (in the case of liquid detergent), depending on the equipment of the machine. With GS 660 the

container for the detergent can be stored inside of the machine. With the other machines, it is stored

separately.

:DVKLQJThe circulating pump conveys the wash water out of the tank via the wash arms and nozzles

onto the wash items. The wash arms move thereby side to side, thus guaranteeing powerful and efficient

cleaning of the wash items. During circulation the wash water is continuously circulated through a filtering

system and the patented Mediamat Cyclo (floating particle separator).

'ULSSLQJRII There is a short pause after washing to allow the wash water to drip off the washing items.

5LQVLQJ During the last programme step, the cleaned items are rinsed with fresh, hot water to remove

residual water and to warm up the wash items for optimum drying outside of the machine. In addition, the

rinse water refreshes the wash water.

:DVKSURJUDPPHV

The utensil washer can be operated with various wash programmes. The respective wash programme is

selected by means of the control panel.

3URJUDPPH 'HVFULSWLRQ

1RUPDOSURJUDPPH Normally soiled items

Medium drying time

6KRUWSURJUDPPH Lightly soiled items

Short/no drying time

,QWHQVLYHSURJUDPPH Heavily soiled items

Long drying time

1RUPDOSURJUDPPHZLWKFROGZDWHU

SUHULQVHRSWLRQDO Items with protein-containing soiling

Coagulation is prevented by rinsing with cold water.

7DQNGUDLQDJHVHOIFOHDQLQJ

Automatic cleaning of the machine:

The wash pump is activated for 30 sec. to clean the wash

tank.

The soiled wash water is pumped off and then the interior

of the machine is rinsed with fresh water.

When the cleaning programme is finished, the utensil

washer switches off automatically.