Winterhalter Gastronom GmbH Pf. 1152 D-88070 Meckenbeuren OI GSR36/GSR36E 89003475 09/00 sch P.2

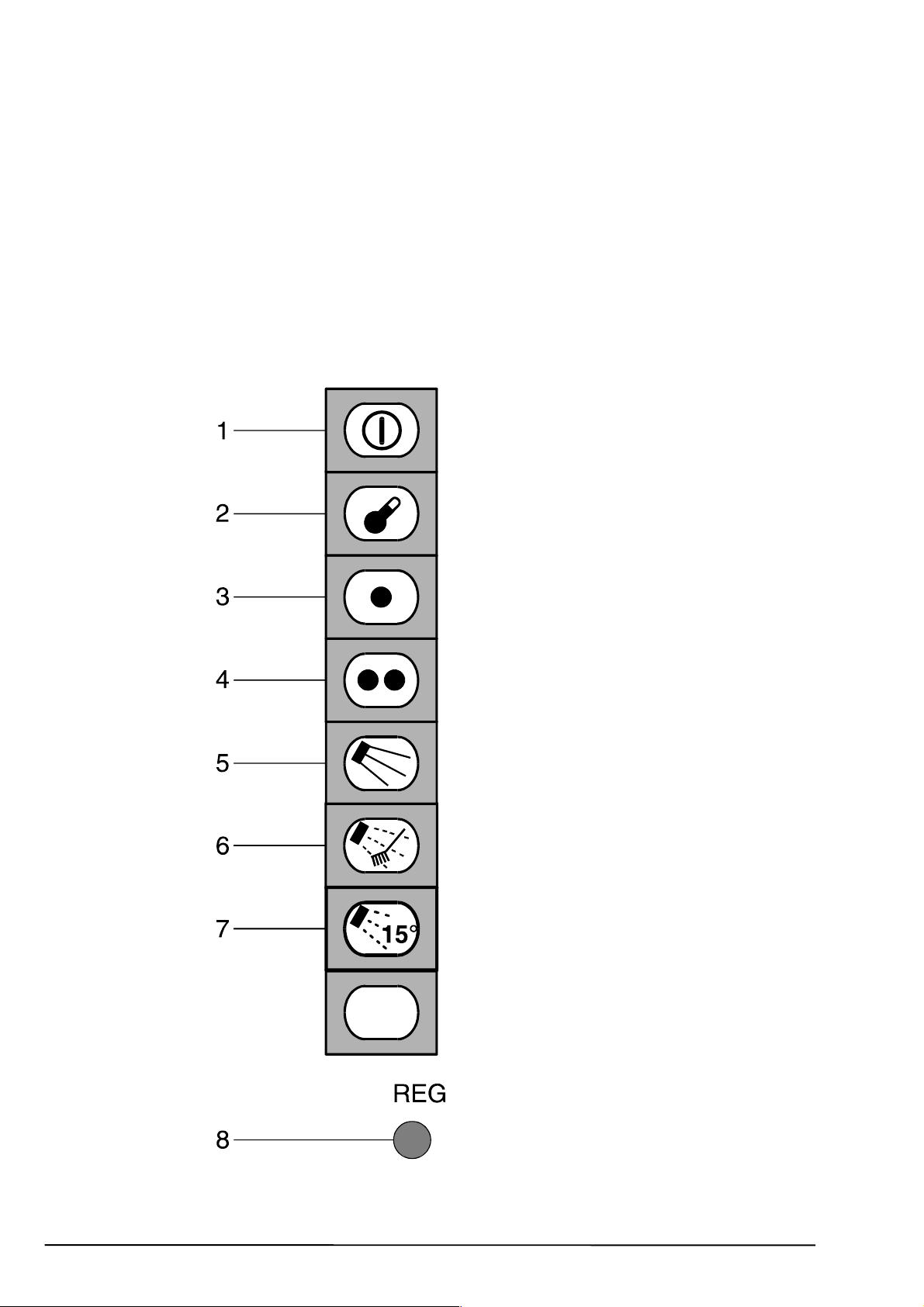

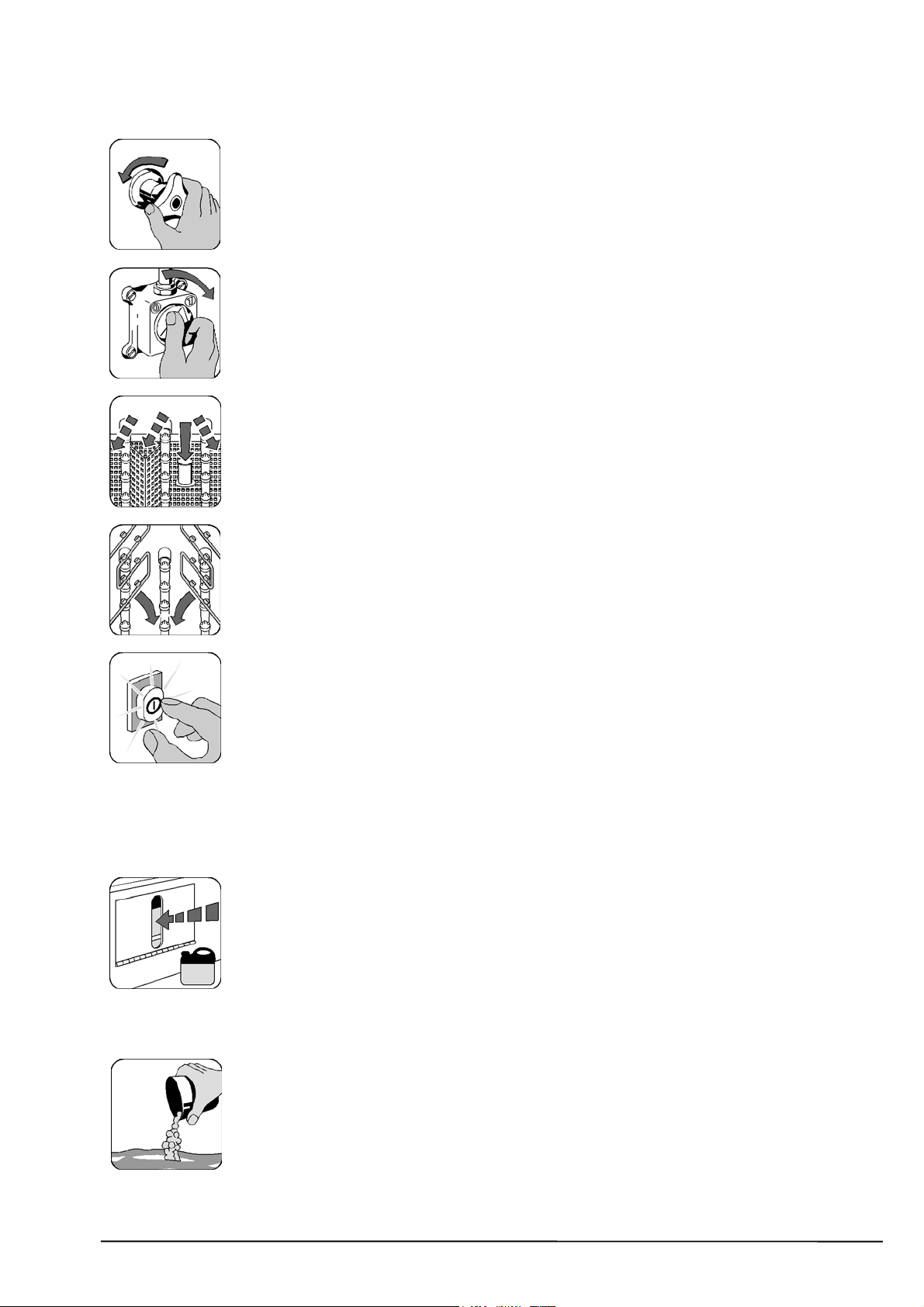

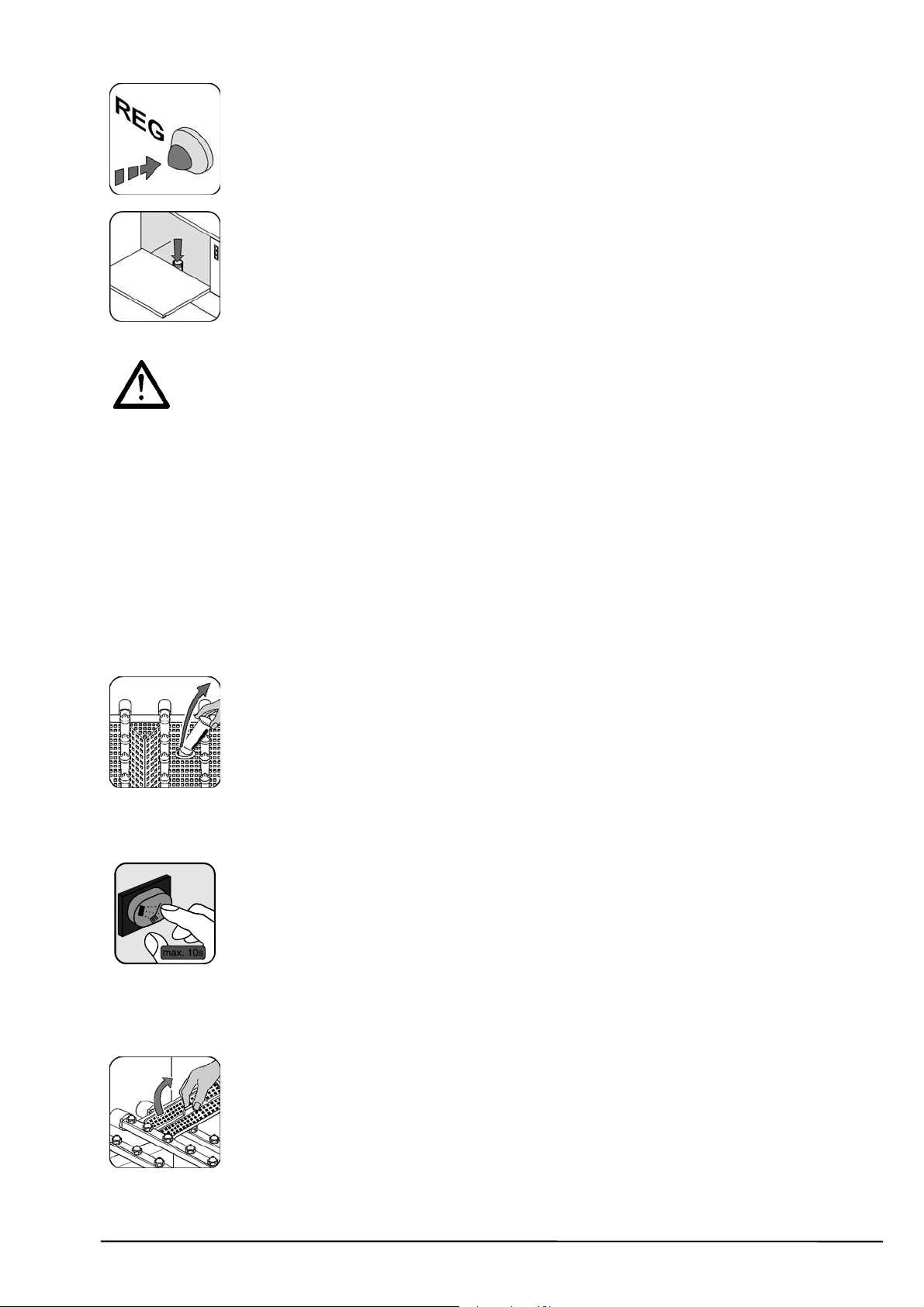

3. Installation and commissioning

The installation of the machine and the service connections to the water supply and drain

pipes must be effected in accordance with „Installation Instructions for Winterhalter Gastro-

nom Dish and Utensils Washing Machines“.

The factory representation of Messrs. Winterhalter Gastronom which is competent for the

site of the machine, has to perform the first commissioning and the instruction of the personal

according to the „Commissioning Instructions for Winterhalter Gastronom Dish and Utensils

Washing Machines“. Therefore please contact this company when the machine has been

connected orderly to the supplay pipes on site.

·Only after finishing all connection works your dishwasher is ready for commissioning.

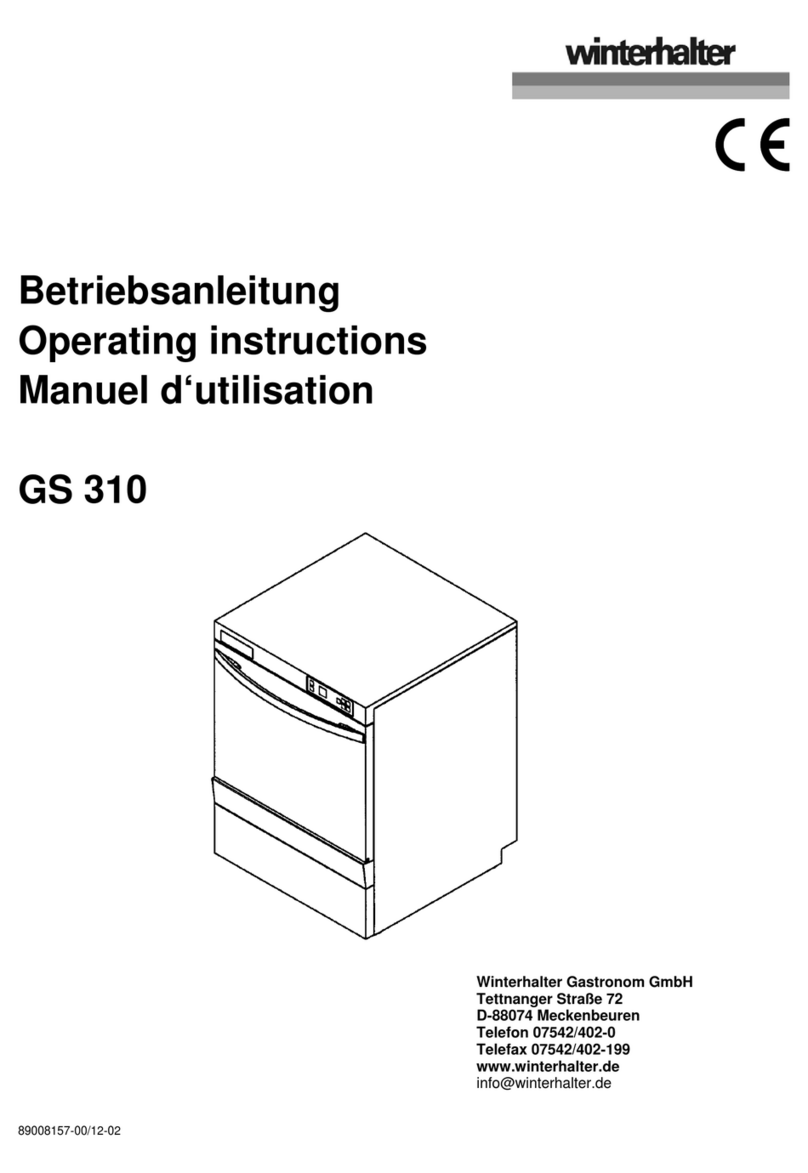

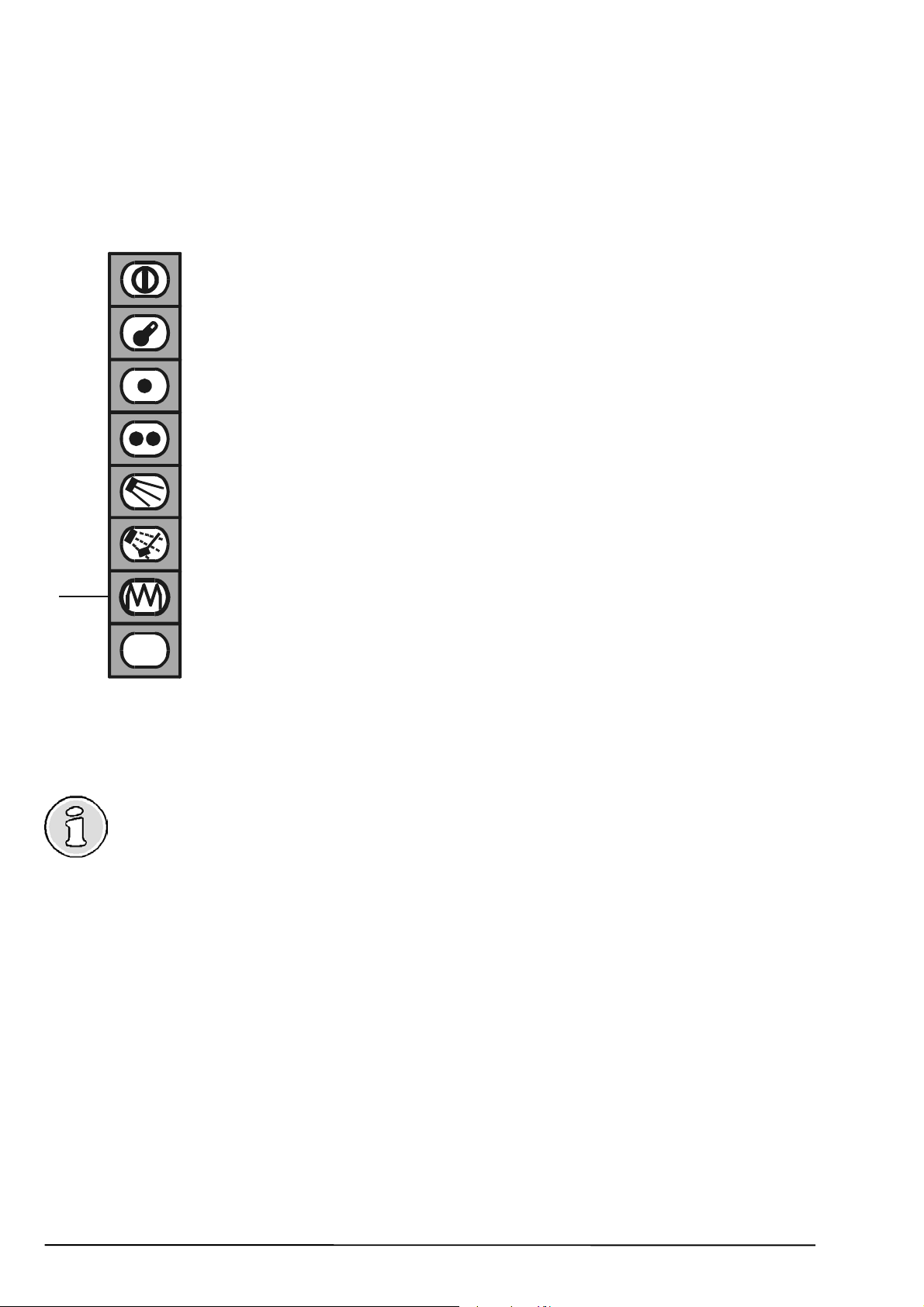

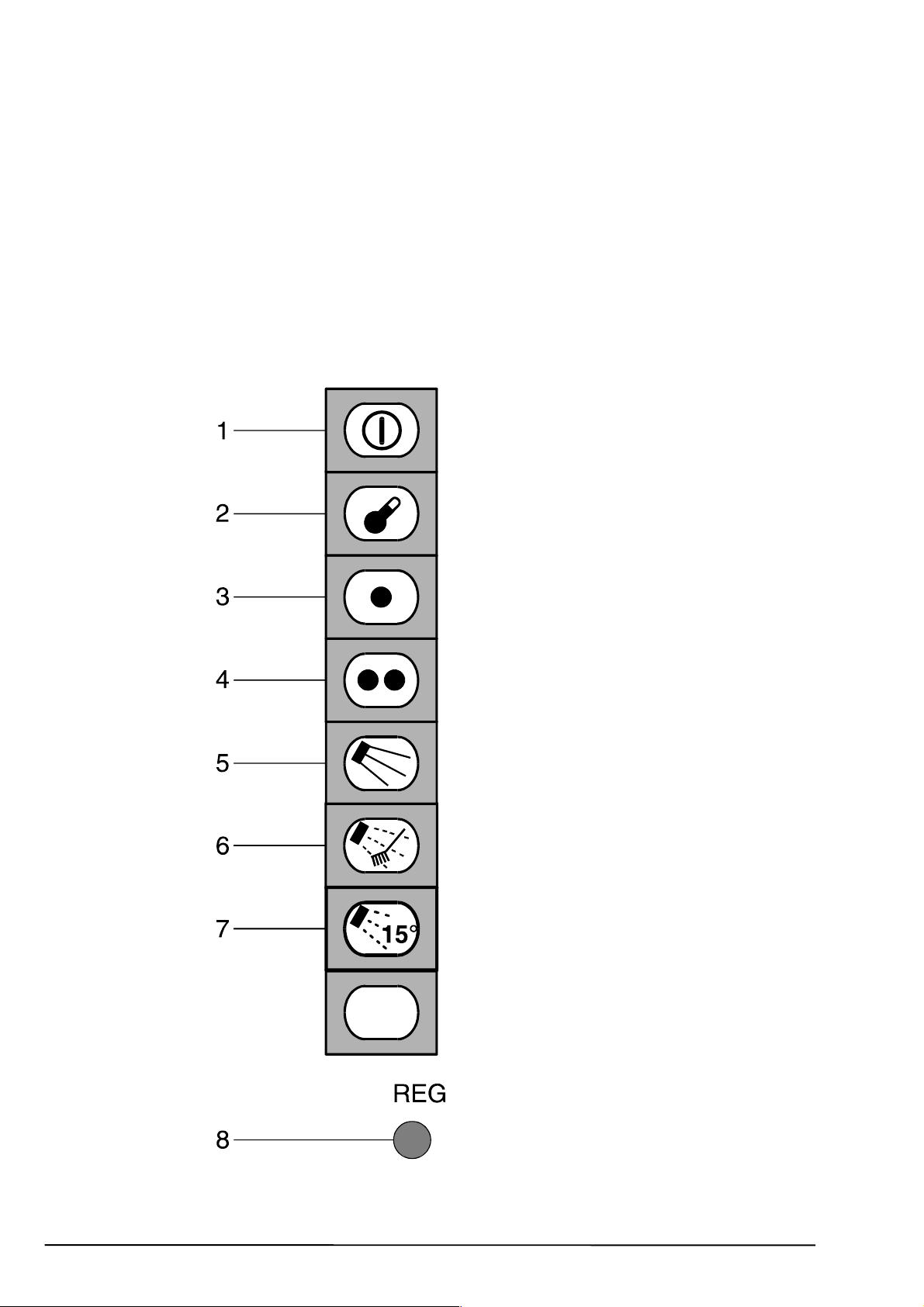

4. Operating and control instruments

1 Mains switch By pressing the machine is

switched on (lights up when

switched on)

By pressing again the machine

is switched off again (extinguis-

hes)

2 „Ready for operation“ This white lamp is lit during

the heating up phase of the tank

water. It extinguishes when the

temperature of the tank water

has reached the required value.

Now washing may be started.

3 Programme 1By pressing the cycle is re-

leased for slightly soiled dishes

(is lit during the cycle).

4 Programme 2By pressing the cycle is re-

leased for strongly soiled dishes

(is lit during the cycle).

5 Continuous washing

6 Tank cleaning

7 Manual cold As long as this button is

prerinsing pressed, the cold water prerin-

sing is in operation.Option.

8 Pilot light „REG“ When lit there is an failure in the

water softening appliance or

lack of salt with the GSR 36 E.

Option at the GSR 36.