Manual

HE OEM 2 | 40-XX | 60-XX

Contents

Declaration of conformity ..........................................................................................................

Notes on safety ............................................................................................................................

General ..........................................................................................................................................................

Identification of symbols in the operating instructions.....................................................................

Personnel qualification ............................................................................................................................

Danger of not observing savety instructions ....................................................................................

Safety-conscious work .............................................................................................................................

Safety instructions for the operator .....................................................................................................

Safety instructions for installation and maintenance work ............................................................

Unauthorised conversion and production of spare parts ...............................................................

Unpermitted operation .............................................................................................................................

Transport and storage .................................................................................................................

Intended use .................................................................................................................................

Product information .....................................................................................................................

Technical data HE OEM -XX -XX ..........................................................................................

Delivery range ...........................................................................................................................................

Pump description ....................................................................................................................

Pump settings and capacity .....................................................................................................

Buttons ......................................................................................................................................................

Service mode setting the capacity range ..........................................................................................

Control panel and LED display .............................................................................................................

Selection of the operating mode and degree of work ..................................................................

Recommendations for selecting a degree of work ........................................................................

Automatic night reduction of power...................................................................................................

Filling and venting the installation ..........................................................................................

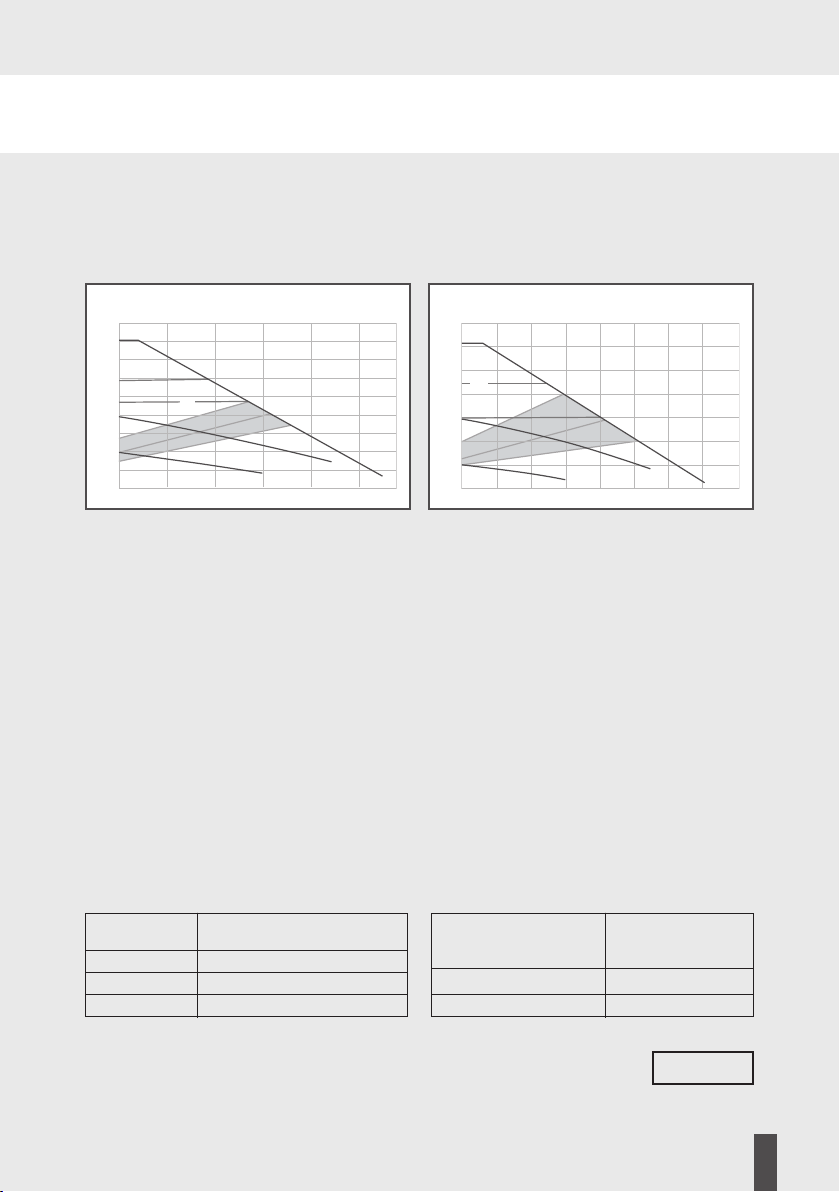

Relationship between pump setting and capacity ................................................................

Capacity characteristics.............................................................................................................

Installation ..................................................................................................................................

Electrical connection .................................................................................................................

Maintenanceservice .................................................................................................................

Malfunctions causes and elimination .....................................................................................

Disposal .......................................................................................................................................

2