3Install-Std-120906

Standard Track

Thread the track onto wheels; lineup the wheels properly in the track grooves. Be careful

not to insert the wheels sideways. You won’t like the result.

Conrm the proper orientation of the door. See the illustrations of Left or Right Stack

doors or Double Ended doors at the top of Page 2. Position the track to ensure: a) it can

be securely attached to the header and b) the Mounting Panel can be securely attached

to the wall or doorjamb.

Stack the door to one end of the track (either side of the opening is OK) and

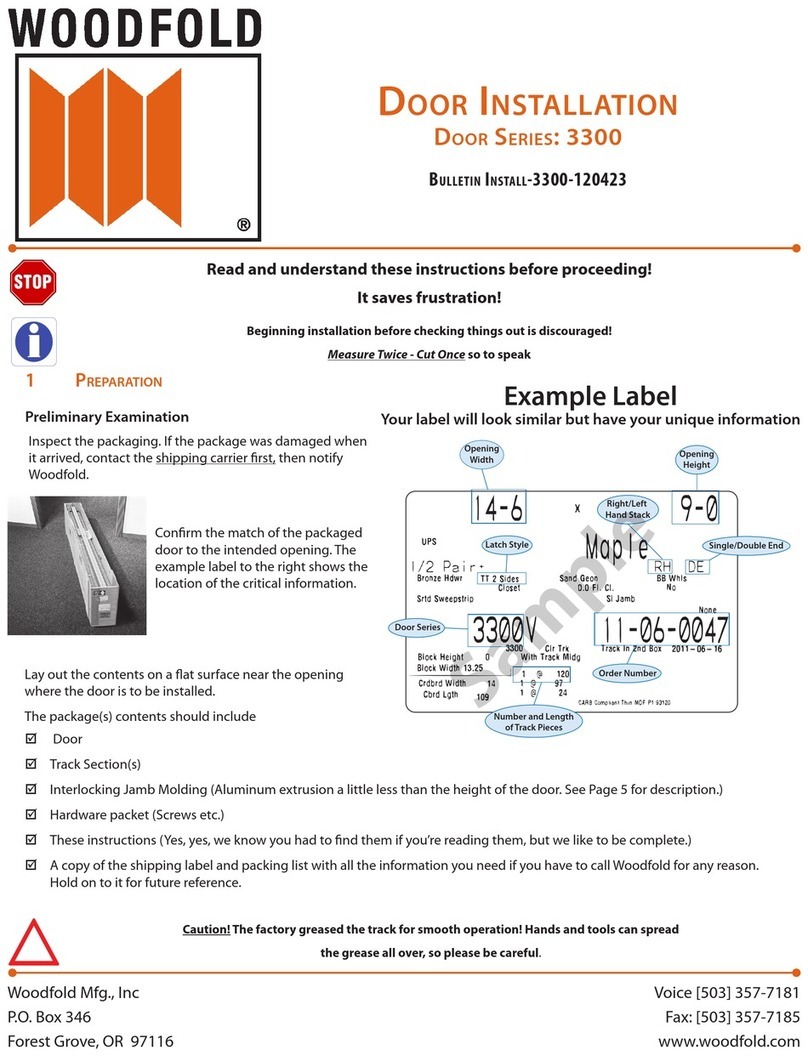

attach the other end of the track to the header. Use #8 x 1½” pan or truss head

screws through the rst 2 holes at the end of the track. Seat the head of the

screw rmly against the track.

If the screws didn’t go into a solid part of the header (soft stu like sheetrock

or acoustical tile doesn’t count) at least ¾”, now would be a good time to go to

the hardware store and get longer #8 Pan Head or Truss Head screws.

Transfer the door to the attached end of the track. Finish attaching the track

with #8 x 1½” pan or truss head screws.

Pin Track (track is in two or more pieces)

Some Pairs are shipped with two track section without alignment pins. If the track sections do not have alignment pin slots go

back to the Standard Track section and butt the track ends together in the middle.

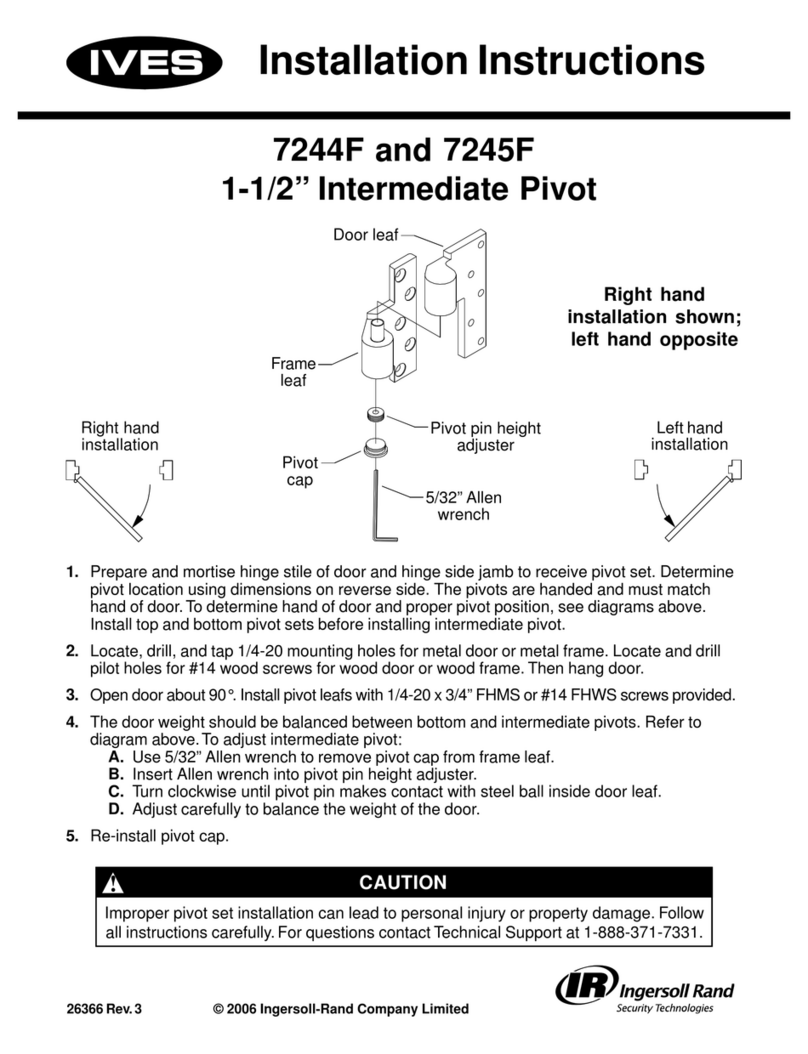

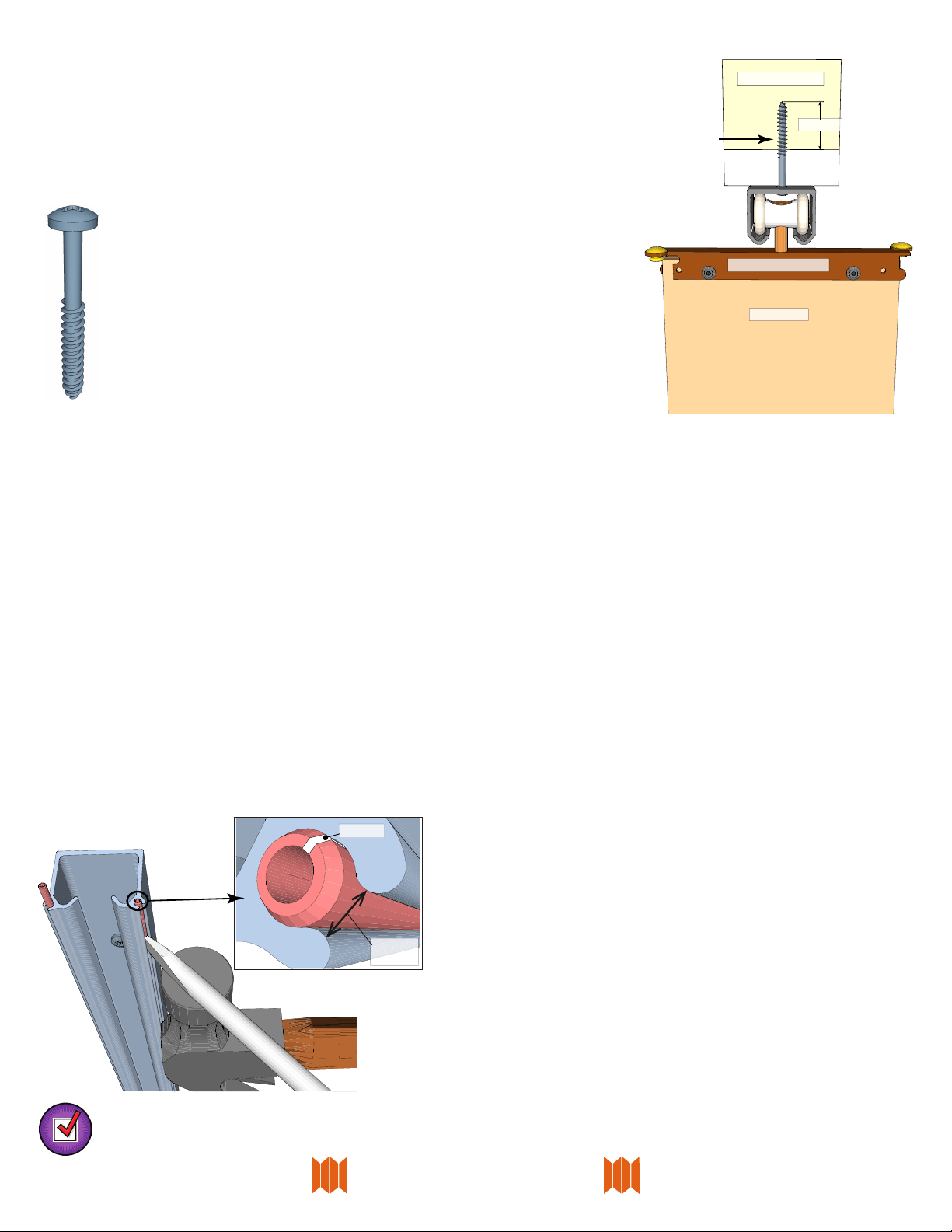

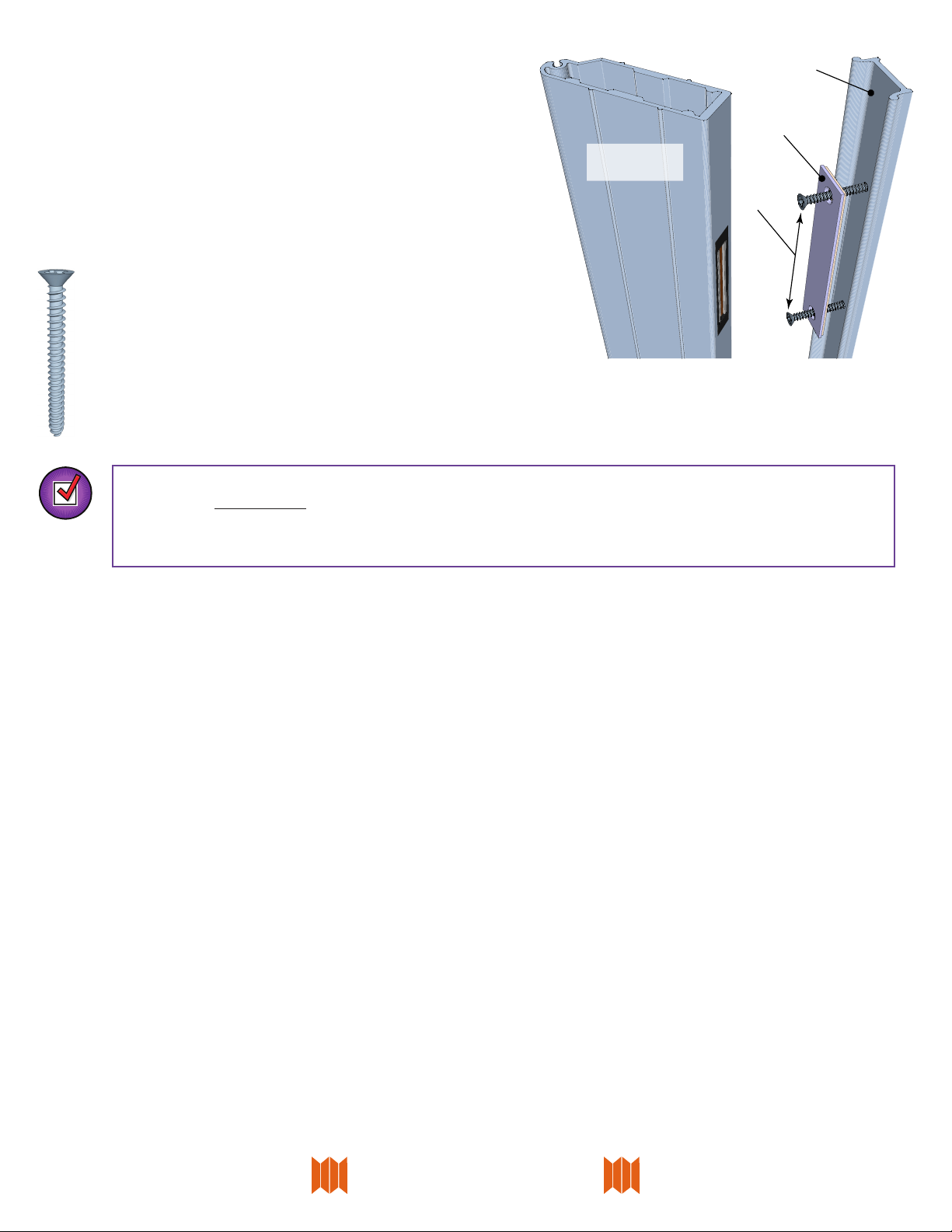

Find the longest piece of track. If they are all the same size, just pick one, any one. Insert the alignment pins into the groove of the

track at the end that will mate to the next section. The split in the pin MUST BE AWAY (perpendicular, see inset illustration below)

from the slot in the track. Drive the spring pins completely into one track using a hammer.

Thread the track onto wheels; lineup the wheels properly in the track grooves. Be careful not to insert the wheels sideways. You

won’t like the result.

Stack the door to one end of the track section and attach the other end of the track to the header. Use #8 x 1½” pan or truss head

screws to attach the track to the header. Start at the jamb side where the door will stack and put in enough screws to accommo-

date the stacked door. Seat the head of the screws rmly against the track.

If the screws didn’t go into a solid part of the header (soft stu like sheetrock or acoustical tile doesn’t count) at least ¾”, now

would be a good time to go to the hardware store and get longer #8 pan or truss head screws.

Transfer the door to the attached end of the track. Finish attaching the track with #8 x 1½”pan or truss head screws.

The doors may be heavy! Don’t be a hero! Let the track do the lifting for you!

Repeat the process of inserting the alignment pins and attaching to the header for each remaining track section.

Check it out! Move the door back and forth along the track looking for smooth operation. Most frequent problems include screw

heads sticking out, wheels sideways or debris in the track.

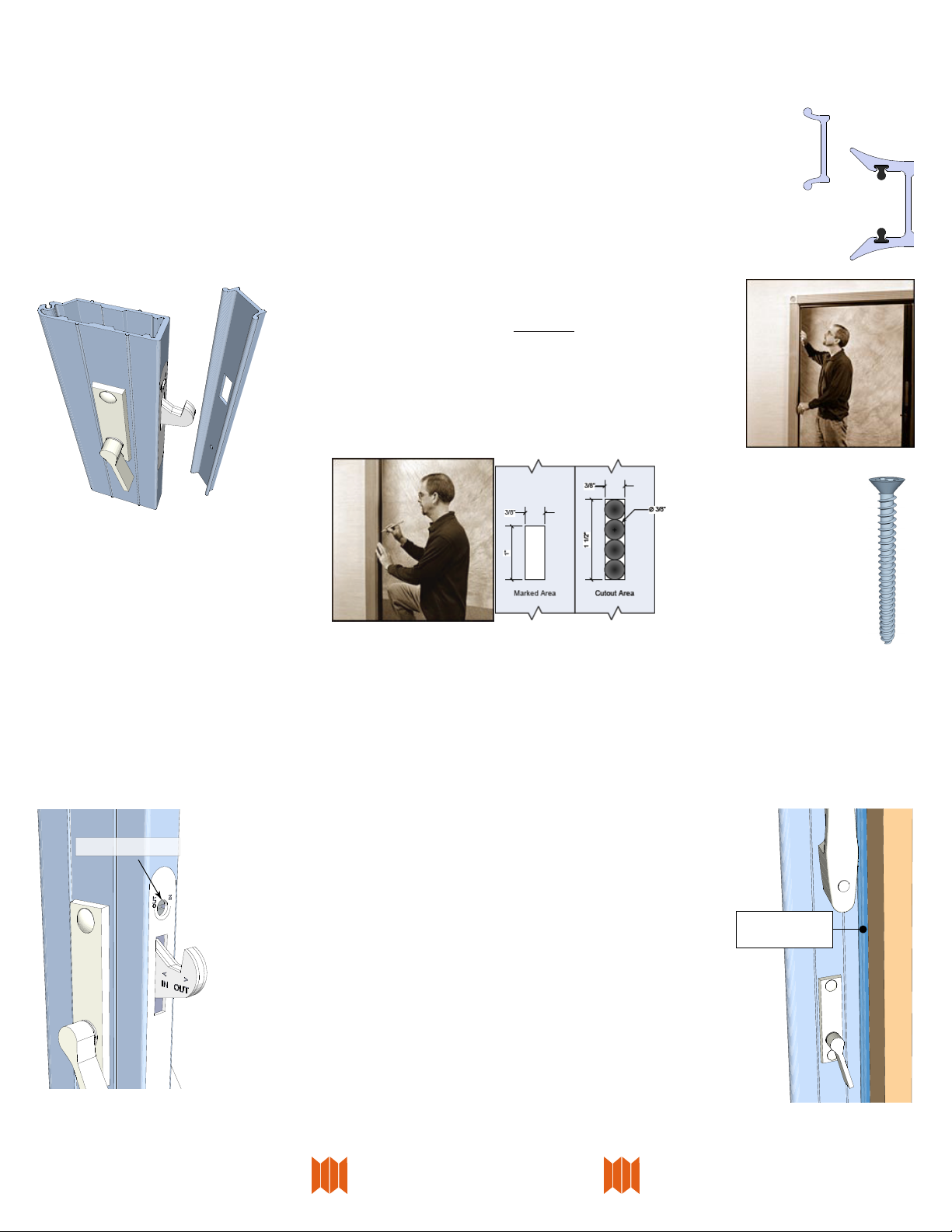

After the track has been secured, drive the alignment pins back halfway into the

second piece of track with a hammer and the edge of a screwdriver.

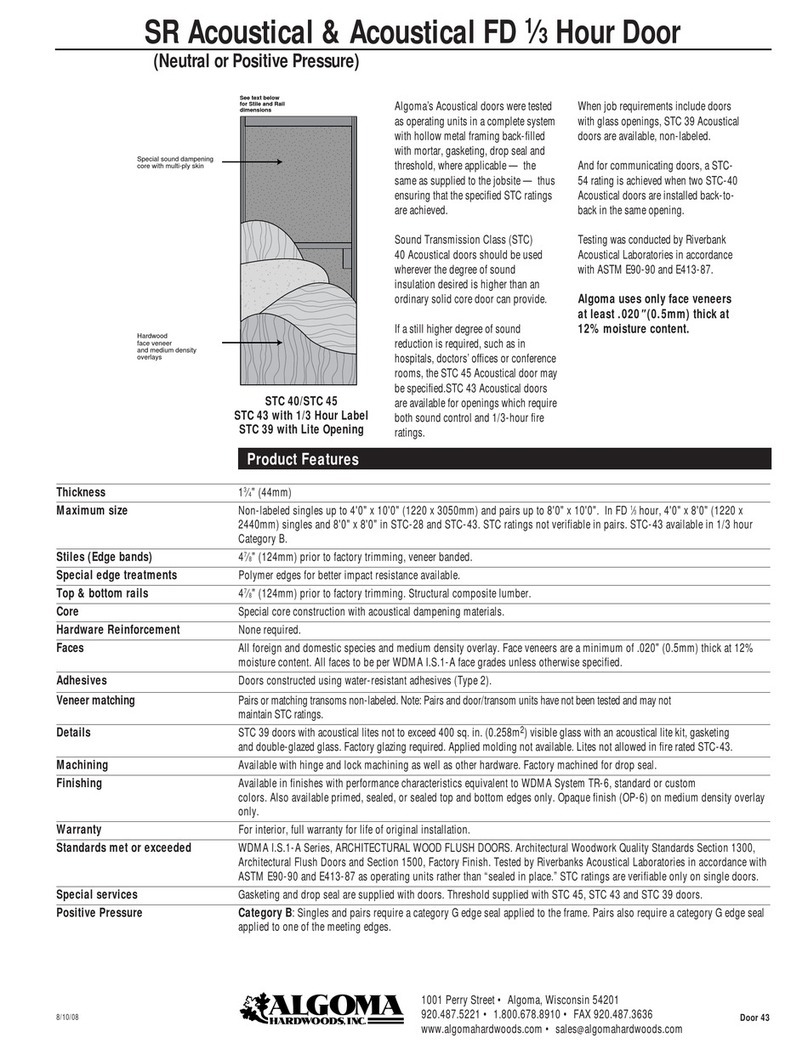

#8 x 1½ Pan or

Truss Head Screw

Pin Hinge Hardware

Body Panel

Structural Material

At least ¾”

Non-structural

Material

#8- 1½” Pan Head

Pin Split

Slot

Opening