8Woody Equipment

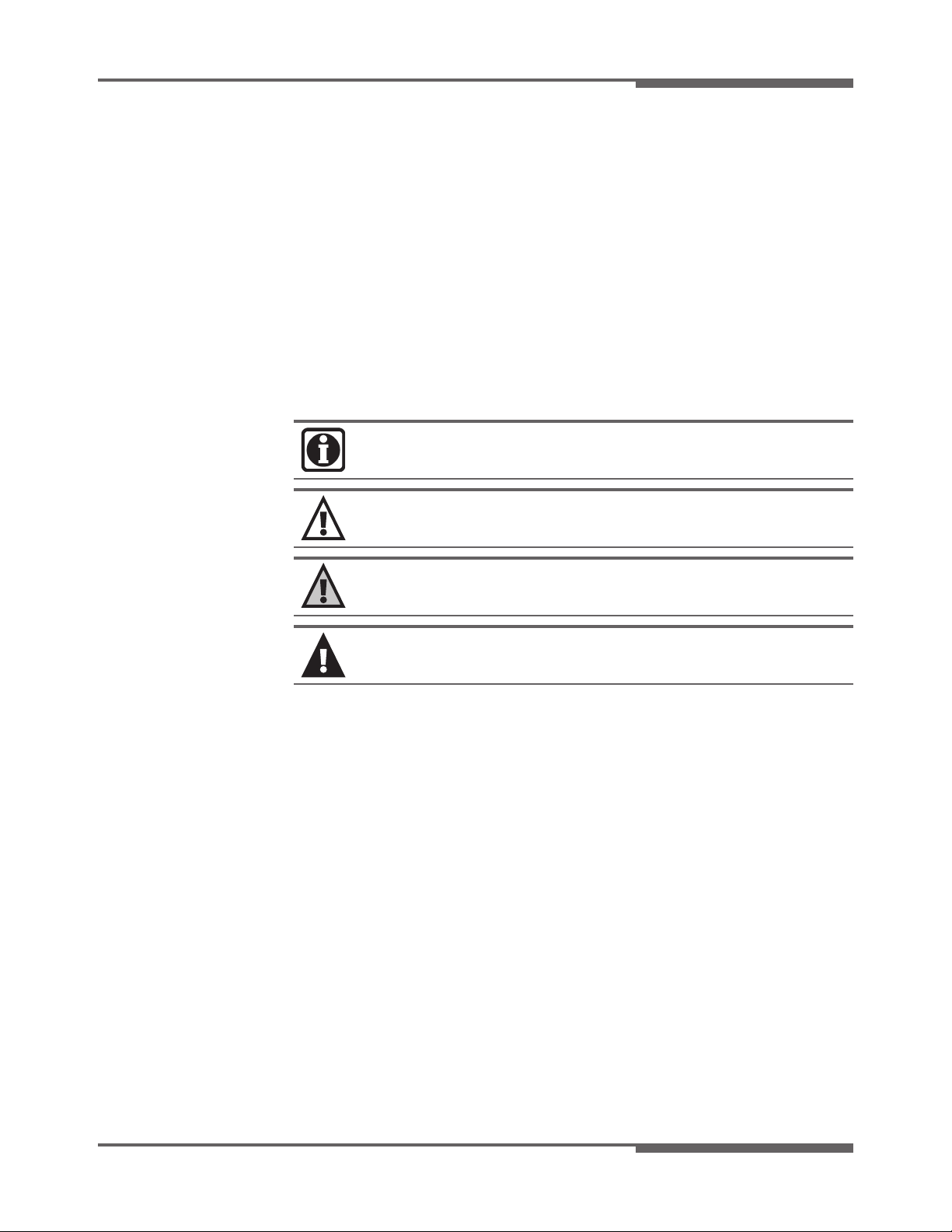

Woody Brushcutter Operator’s and Maintenance Manual

Safety Guidelines

WARNING. This section provides guidelines to help ensure the

safety of the people working with and around the Brushcutter and to

prevent damage to the Brushcutter. Woody assumes no liability or

responsibility for injury or damages that may arise if these guidelines

are not followed.

General guidelines

• Follow all federal and state or provincial safety regulations for hydraulic

mechanisms, lifting devices, grapples, spillage, and disposal of hydraulic oil.

• Ensure that the Brushcutter is safety-equipped according to federal and

state or provincial regulations.

Service and maintenance guidelines

• Installation and removal of the Brushcutter, as well as all service and repairs,

must be carried out by qualied hydraulic mechanics and/or an authorized

repair shop.

• Welding on the Brushcutter can cause structural damage. Before welding on

the Brushcutter:

• contact your Woody Equipment or your representative for authorization,

• disconnect the ECU power plug, both battery cables, radio, and all elec-

tric throttle and alternator connections, and

• make sure the ground wire does not make contact with a moving part of

the Brushcutter or carrier (grear box, bearings, cylinder, etc.).

• Loose or over-torqued bolts can cause parts to separate which can result in

property damage, severe injury, or death. Keep the bolts correctly torqued

by inspecting the nuts and bolts regularly according to the Maintenance

Schedule on page 16. Please refer to your parts manual for torque value

specications.

Power line guidelines

To prevent the Brushcutter or carrier from contacting a power line, do the

following:

• Before starting to work with the Brushcutter, inspect the work area for power

lines that you might have to work under or close by.

• Before work starts, contact the utility company responsible for electricity in

the work area and request that the power in that area be disconnected.

• Treat all power lines as live and dangerous. It may not be possible to discon-

nect the power in the work area.

• Keep a distance between power lines and all parts of the Brushcutter, and

the carrier according to this formula: twice the line insulator length plus 10

feet.