Contents

1.

Installation

Regulations

..........

:

.....................................

Page

2

2.

General

Information

......................................................

Page

2

3.

Data

Technical

................................................................

Page

4

4.

Siting

the

Appliance

......................................................

Page

5

5.

Siting

the

Flue

Terminal

................................................

Page

6

6.

Air

Supply

.......................................................................

Page

7

7.

Sealed

System

................................................................

Page

7

8.

Open

Vent

Primary

Water

System

...............................

Page

8

9.

Domestic

Hot

Water

......................................................

Page

9

·1

. Installation

R1egulations

1.1

Gas

Safety

(Installation

and

Use)

~egulations

1984

All

gas

appliances

must

be

installed:

by

a competent

person

in

accordance

with

the

above

regulations.

Failure

to

install

appli·

ances

correctly

could

lead

to

prosecution.

1.2

The

manufacturers

notes

must not

be

taken,in

any

way,as

overriding

statutory

obligations.

1.3

The

compliance

with

a

Briti<>h

Stnnrl;ml

rlnAs

nnt,

nf

itsAlf,

r.nn·

fer

immunity

from

legal

obligations.

In

particular

the

installation

of

this

appliance

must

be

in

accordance

with

the

relevant

require·

ments

of

the

Gas

Safety

(Installation

and

Use)

Regulations

1

984

as

amended,

current

lEE

Wiring

Regulations,

local

Building

Regula·

tions,

Building

Standards

(Scotland)(Consolidation)

and

byelaws

of

the

local

Water

Company.

Health

and

Safety

Document

No.

635

(Electricity

at

Work

Regulations).

It

should

be

in

accordance

with

the

relevant

recommendations

of

the

following

British

Standards.

BS

6798:1987

Specification

for

installation

of

gas

fired

hot

water

boilers

of

rated

input

not

exceeding

60

kW.

BS

5449:1990

Central

Heating

for

Domestic

Premises.

BS

5546:1990

Installation

of

gas

hot water

supplies

for

domes·

tic

purposes.

BS

5440:1:1990

Flues

and

Ventilation

for

gas

appliances

of

rated

input not

exceeding

60

kW:

Flues.

BS

5440:2:1989

Flues

and

Ventilation

for

gas

appliances

of

rated

input not

exceeding

60kW:

Air

Supply.

BS

6891

:1988

Installation

of

low

pressure gas

pipework

installa·

tions

up

to

28

mm

(R

1

).

1.4

To

ensure that the installation

will

perform

to

the highest

standards, the

system

and

components should

conform

to

any

other

relevant

British

Standards

in

addition

tci

those mentioned

in

the instructions.

2.

General

Information

2.1

This

appliance

is

not

suitable

for

external installation.

2.2

The

appliance controls are set to provide a maximum

output

of

24

kW

for

the domestic hot water and a central

heating

load

of

up

to

16.1

kW.

2.3

The

appliance

has

a permanent

pilot.

2.4

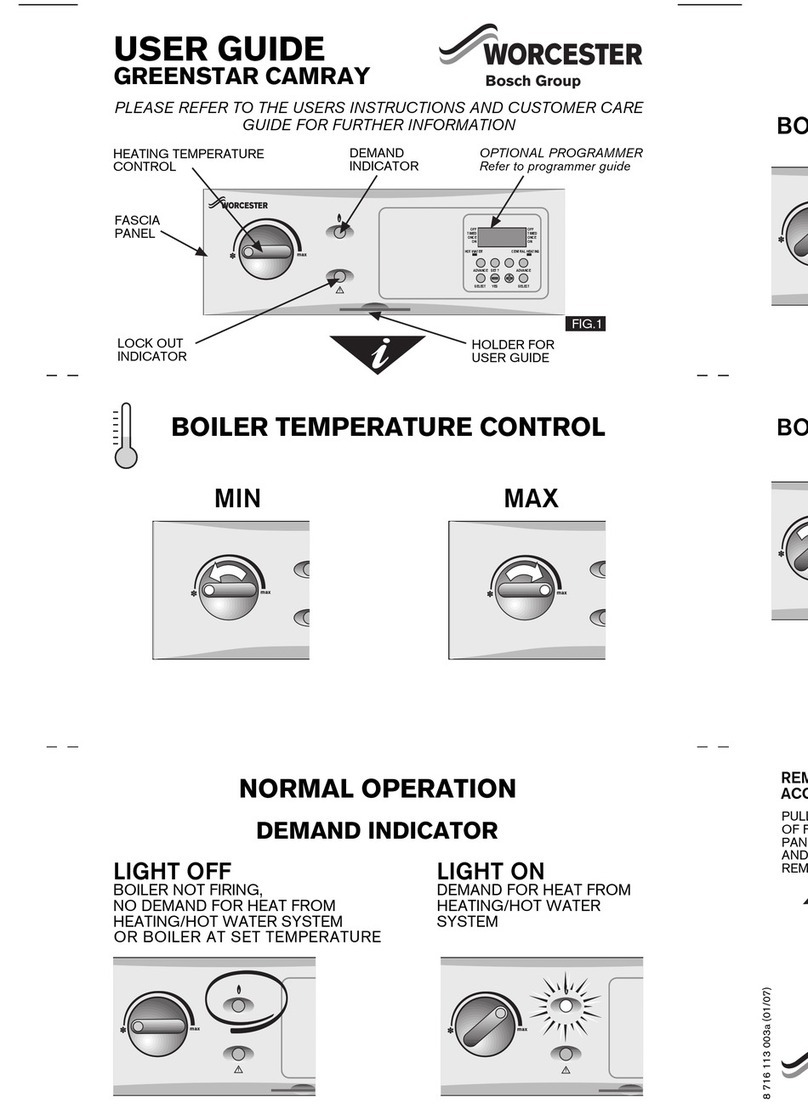

PRINCIPLE

APPLIANCE

COMPONENTS

See

Fig.

1.

A

low

thermal capacity

Gas

to

Water

heat

exchanger.

A

Water

to

Water

heat

exchanger

to

provide

domestic

hot

water.

Ft,dly

modulating

controls

in

the central heating and domestic

hot water

modes

of

operation.

An

expansion

vessel,

pressure

gauge

and pressure

relief

valve.

Aby-pass

for

the

central

heating system.

Temperature

safety

cut·out

controls.

2

10.

Electrical

......

,

..................................................................

Page

10

11.

Installation

.....................................................................

Page

14

12.

Commissioning

..............................................................

Page

17

13.

Instructions

to

the

User

................................................

Page

18

14.

Inspection

and

Servicing

..............................................

Page

19

15.

Replacement

of

Parts

....................................................

Pc;~ge

21

16.

Short

Parts

List

..............................................................

Page

28

17.

Operational

Flow

Diagram

............................................

Page

29

18.

Fault

Finding

...................................................................

Page

31

Awater

flow

regulator.

Astandard horizontal

flue

assembly

giving

flue

lengths

from

229

mm

to

420

mm.

An

optional

extra extension

flue

kit

to

provide

for

flue

lengths

up

to

559

mm

long.

An

optional

facia

mounted

programmer

instead

of

the

standard

Operating

Switch.

2.5

ELECTRICAL

SUPPLY

Main5

5upply:

2-1

OV

··,

50

I

Iz,

150 wiltts. External

fuse

3A.

Internal

fuses:

T2A

(F1)

and

T315mA

(F2).

2.6

GAS

SUPPLY

The

boiler

requires

2.81

m'

/h

(99.3

ft'/hr)

of

gas.

The

gas

meter

and

supply

pipes

must

be

capable

of

supplying

this

quantity

of

gas

in

addition

to

the demand

from

any

other

appliances

being

served.

The

table

below

gives

an

indication

of

limiting

gas

pipe

lengths and the allowance

to

be made

for

fittings.

Refer

to

BS6891

for

further

information.

The

meter governor should

deliver

a dynamic pressure

of

20

mbar

(Sin

wg.)

at the

appliance.

The

complete

installation,

including

the

gas

meter,

must

be

test-

ed

for

soundness and

purged.

Refer

to

BS

6891

.

TOTAL

LENGTH

OF

GAS

SUPPLY

PIPE

(metres)

Pipe

Diameter

3 6 9

(mm)

Gas

Discharge

Rate

(m3/h)

2.9

--

15

8.7

5.8

4.6

22

18.0 12.0

9.4

28

Note:

Each

fitting

used

in

the

gas

line

from

the

meter

is

equivalent

to

a

length

of

straight

pipe

which

must

be

added

to

the

straight

pipe

length

to

give

the

total

length.

ie:

Elbow

=

0.5

metres,

Tee

=

0.5

metres,

90°

Bend

=

0.3

metres.

2.7

PACKING

The

appliance and

flue

components

are

packed

in

separate

car-

tons.

2.8

GENERAL

INSTALLATION

The

appliance

is

supplied

for

connection

to

a sealed system but

is

suitable

for

use

with

an

open

vent

system.

The

connections

are

supplied

as an optional

kit.

The

specified

ventilation

openings

made

into

a

wall

or

compart-

ment

door

must not

be

obstructed.

If

the

appliance

is

to

be

fitted

into

a compartment then the

com-

partment must

conform

to

the

requirements

of

BS

6798:

1987:

Section

6.

Do

not

place

anything

on

top

of

the

appliance.

The

clearances

specified

for

servicing

must

be

maintained.