GENERAL SAFETY RULES

WARNING. Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future

reference.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c.Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk

of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result

in serious personal injury.

b. Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will

reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on

the switch or energising power tools that have the

switch on invites accidents.

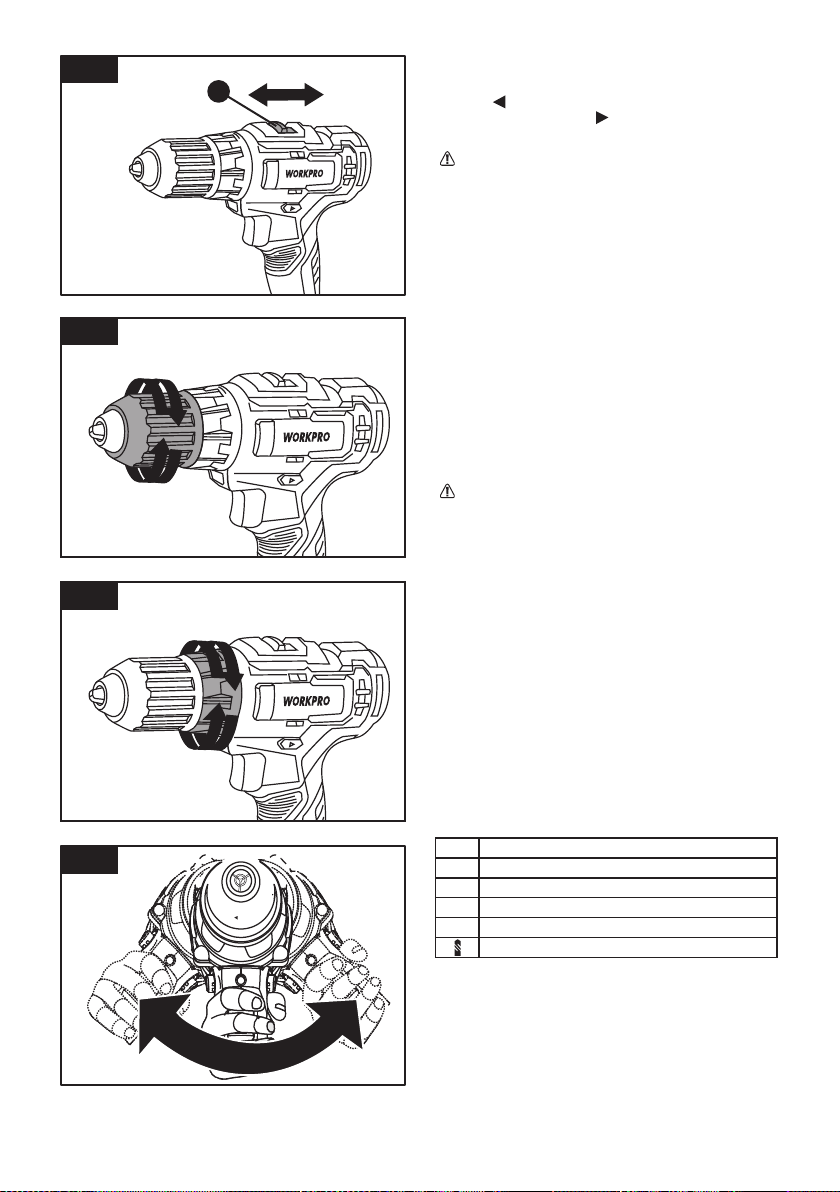

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in

personal injury.

e. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust

collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of

tools allow you to become complacent and ignore

tool safety principles. A careless action can cause

severe injury within a fraction of a second.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it

was designed.

b. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

c. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures

reduce the risk of starting the power tool acciden-

tally.

d. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

battery pack.

Do not use the charger if it has been subjected to a

heavy knock, dropped or otherwise damaged in

anyway. Take the charger to an authorised service

centre for a check or repair.

Do not disassemble the charger. Opening or

removing covers may expose you to dangerous

voltages or other risks. Incorrect reassembly can

cause electric shock when you use the tool or

charger again. Take the charger to a power tool

repair centre when service or repair is required.

Incorrect re-assembly may result in the risk of fire,

electric shock or electrocution. To reduce the risk of

electric shock, do not disassemble any part of the

product.

DANGER. If the battery pack is cracked or damaged

in any other way, do not insert it in the charger

Do not plug anything other than your Workpro tool

into the charger, as other objects may touch

dangerous voltage points or short out parts, which

could result in fire or electric shock.

Do not place the tool or charger on an uneven

surface, as a fall may cause serious damage.

Never place the tool or charger near or over a heat

source such as a radiator or heater.

Do not operate the charger in a cabinet or other

enclosure unless proper ventilation is provided.

Use the battery charger indoors only.

WARNING. Do not allow any liquid to come into

contact with the charger. There is a danger of

electric shock. Do not position the tool or battery

charger near water; for example, near a sink, wash

bowl or toilet. Do not spill liquid of any kind on the

tool or charger. Doing so may short out parts,

Causing damage to the product and creating the

risk of fire or electric shock.

To reduce the risk of an electric shock, unplug the

charger from the power supply before attempting to

clean it. To clean tool or charger, wipe with a damp

cloth. Use of any other cleaners is not recommended.

Do not place any object on to, or allow anything to

rest on the charger.

Make sure that the charger cable is positioned

where it will not be stepped on, tripped over or

otherwise subjected to damage or stress. Keep the

lead away from operating machinery.

Do not pull on the lead of the charger to disconnect

it from the mains power socket.

Do not use an extension cord unless it is absolutely

necessary. The use of an improper extension cord

could cause the risk of fire, electric shock or

electrocution.

Never attempt to connect two chargers together.

Do not charge batteries or use the tool and battery

pack in locations where the temperature may be

below 40°F or exceed 104°F such as alongside

sheds or metal structures.

The battery can be charged or operated at

temperatures between 40° F and 104° F.

Never charge your lithium ion battery below or

above temperatures recommended otherwise fire

or serious damage to the battery pack may occur.

The most suitable temperatures to charge the battery

pack are between 68° F -77° F.

If you wish to charge a second battery pack, unplug

the charger from the mains supply and leave it for at

least 15 minutes. After this time you can charge a

second battery pack.

ADDITIONAL SAFETY INSTRUCTIONS

RELATED TO THE BATTERY PACK AND

BATTERY SAFETY

Use only the WORKPRO batteries supplied with the

WORKPRO Tool or WORKPRO-approved

replacements.

Do not use the battery to power any device other

than the WORKPRO tool it was sold with.

Charge the battery only with the WORKPRO charger

supplied with the tool or WORKPRO-approved

replacements and according to the instructions in

the WORKPRO Instruction Manual.

Do not charge the battery in a place where static

electricity is generated nor let the battery touch

something that is statically charged.

The battery can be stored at temperatures between

40° F and 104° F.

Never store or leave your lithium ion battery in

temperatures over that recommended otherwise

fire may occur.

Do NOT store the Lithium Ion battery anywhere that the

temperature can easily reach higher temperatures than

recommended -this includes garden type sheds, and

Vehicles where the inside temperature can climb to

dangerous levels in the direct sunlight and on high

temperature days. THINK BEFORE LEAVING YOUR

LITHIUM ION BATTERY PACK IN STORAGE.

The battery can be charged or operated at

temperatures between 40° F and 104° F.

NEVER CHARGE YOUR LITHIUM ION BATTERY

BELOW OR ABOVE TEMPERATURES RECOM-

MENDED OTHERWISE FIRE OR SERIOUS

DAMAGE TO THE BATTERY PACK MAY OCCUR.

The most suitable temperatures to charge the

battery pack are between 68 -77° F.

Always allow the battery pack to cool down after

charging, do not place it in a hot environment such

as a metal shed or open trailer left in the sun.

Take care where the tool is stored. Do not store in

areas of corrosive fumes, or salt air or similar

conditions. Try and store the tool in the packaging

supplied with the tool.

Do not dispose of the battery in a fire or put the

battery into a microwave oven, conventional oven,

dryer, or high-pressure container. Under these

conditions, the battery may explode.

Never attempt to open the battery pack, puncture

the battery or subject the battery to strong physical

shock.

If the plastic housing of the battery pack breaks

5