Rev 3.1/5-17 6 PAD OPTIONS: #35240

5) Whenever the original instruction manual for the vacuum equipment refers to Maximum Load

Capacities, be sure to use the

revised

Maximum Load Capacities, as calculated above.

TO CALCULATE THE REVISED PAD SPREAD

When the model of vacuum pad has been changed on vacuum equipment, this normally results

in different Pad Spread dimensions, due to differences in the Maximum Outside Diameter of

vacuum pads (regardless of the nominal pad diameter). Calculate the revised Pad Spread

dimensions as follows:

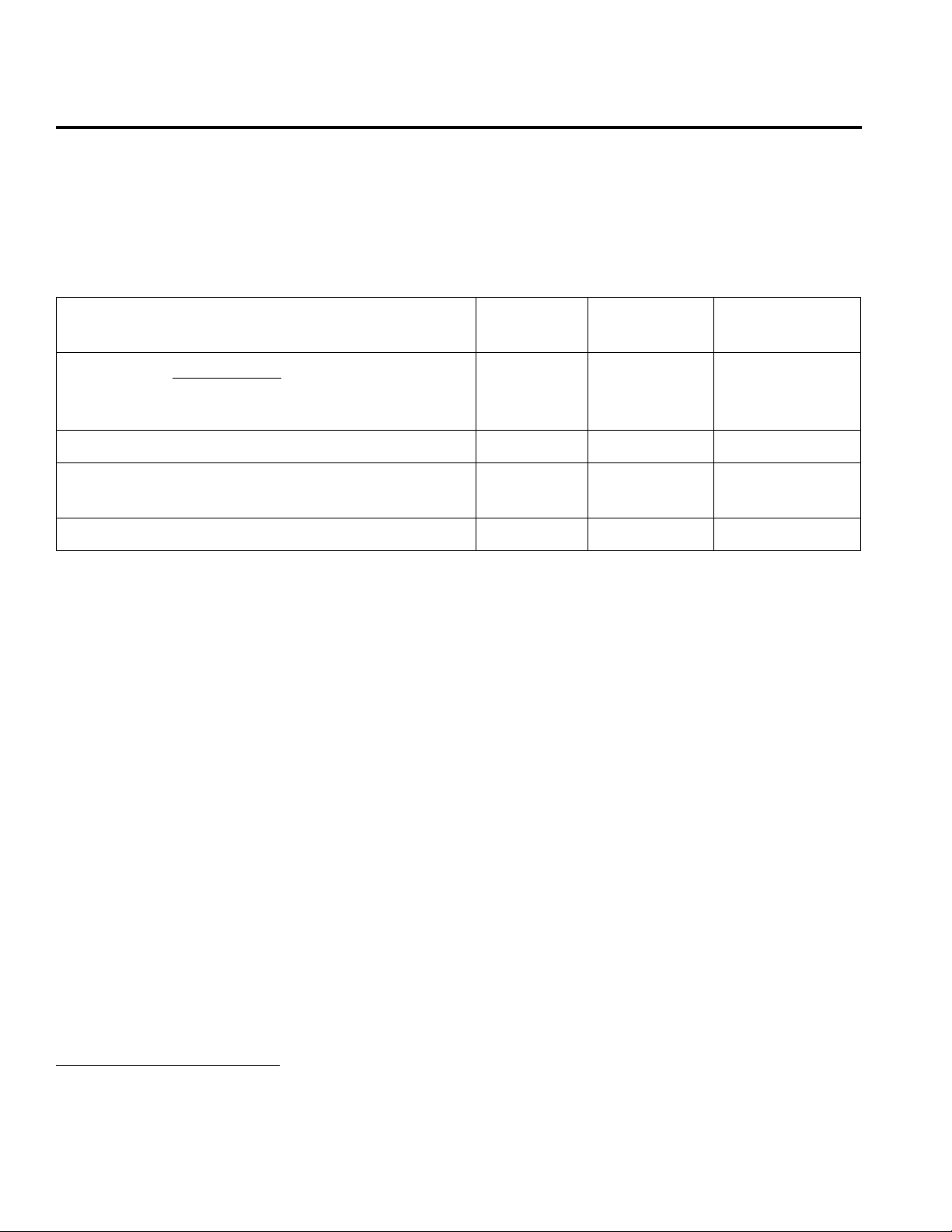

1) Find the previous and current models of vacuum pads (see SPECIFICATIONS: ALTERNATIVE

VACUUM PADS &RELATED SPECIFICATIONS). Then find the corresponding Maximum Outside

Diameter for each pad model.

For example, if the previous pad model was G3370 and the current model is VPFS9, the

Maximum Outside Diameters are 12-1/16" [306 mm] and 9-19/32" [244 mm],

respectively.

2) Subtract the smaller pad diameter from the larger one, to find the difference in diameters.

Using Pad Spread dimensions shown in the original instruction manual for the vacuum

equipment, either add or subtract this difference from the Pad Spread, in accordance with the

size of pads currently installed on the vacuum equipment (ie, larger or smaller diameter).

The results are the

revised

Pad Spread dimensions.

For example, the difference in diameters for pad models G3370 and VPFS9 is 12-1/16"

minus 9-19/32" equals 2-13/32" [306 mm –244 mm = 62 mm]. Since the change is to a

smaller pad diameter, simply subtract the difference from the relevant Pad Spread

dimensions.

3) Replace the Pad Spread dimensions shown in the original instruction manual with the

revised

Pad Spread dimensions.

4) Whenever the original instruction manual for the vacuum equipment refers to Pad Spread

dimensions, be sure to use the

revised

Pad Spread dimensions, as calculated above.

TO DETERMINE RESTRICTED USE OF RUBBER COMPOUNDS

The length of Outdoor Service is provided (see SPECIFICATIONS: ALTERNATIVE RUBBER COMPOUNDS

&RELATED CHARACTERISTICS) in order to determine the minimum interval for vacuum pad

replacement (see MAINTENANCE: VACUUM PAD MAINTENANCE: Pad to Load Friction Coefficient).

The Maximum Load Surface Temperature is provided (see SPECIFICATIONS: ALTERNATIVE RUBBER

COMPOUNDS &RELATED CHARACTERISTICS) in order to avoid loads with surface temperatures which

could damage the vacuum pads. Attempting to lift loads with greater than recommended

surface temperatures could result in a load release and potential injury to the equipment

operator or others nearby.