https://www.XPOtool.com Item 62994 Page 3

The Tool Experts

01 2022-1

Introduction

Thank you for purchasing this quality product. To minimise the risk of injury we urge that our clients

take some basic safety precautions when using this device. Please read the operation instruc-

tions carefully and make sure you have understood its content.

Keep these operation instructions safe.

Product properties

•Being a handy and at the same time powerful ultra-light, this welding machine can easily be

carried on the shoulder strap. The device is suitable for a wide range of different applications

and can easily be used in different places using a long extension cable. On construction sites it

can be operated with an electricity generator, too.

•The welding voltage and wire speed are adjusted with a single control depending on the thick-

ness of the welding plate. This makes it particularly easy to set the correct values.

•The welding arc length, determining the welding temperature, is set with a second control; once

you have found the right values, it is usually not necessary to change them again, even if you

continue with thicker or thinner sheets.

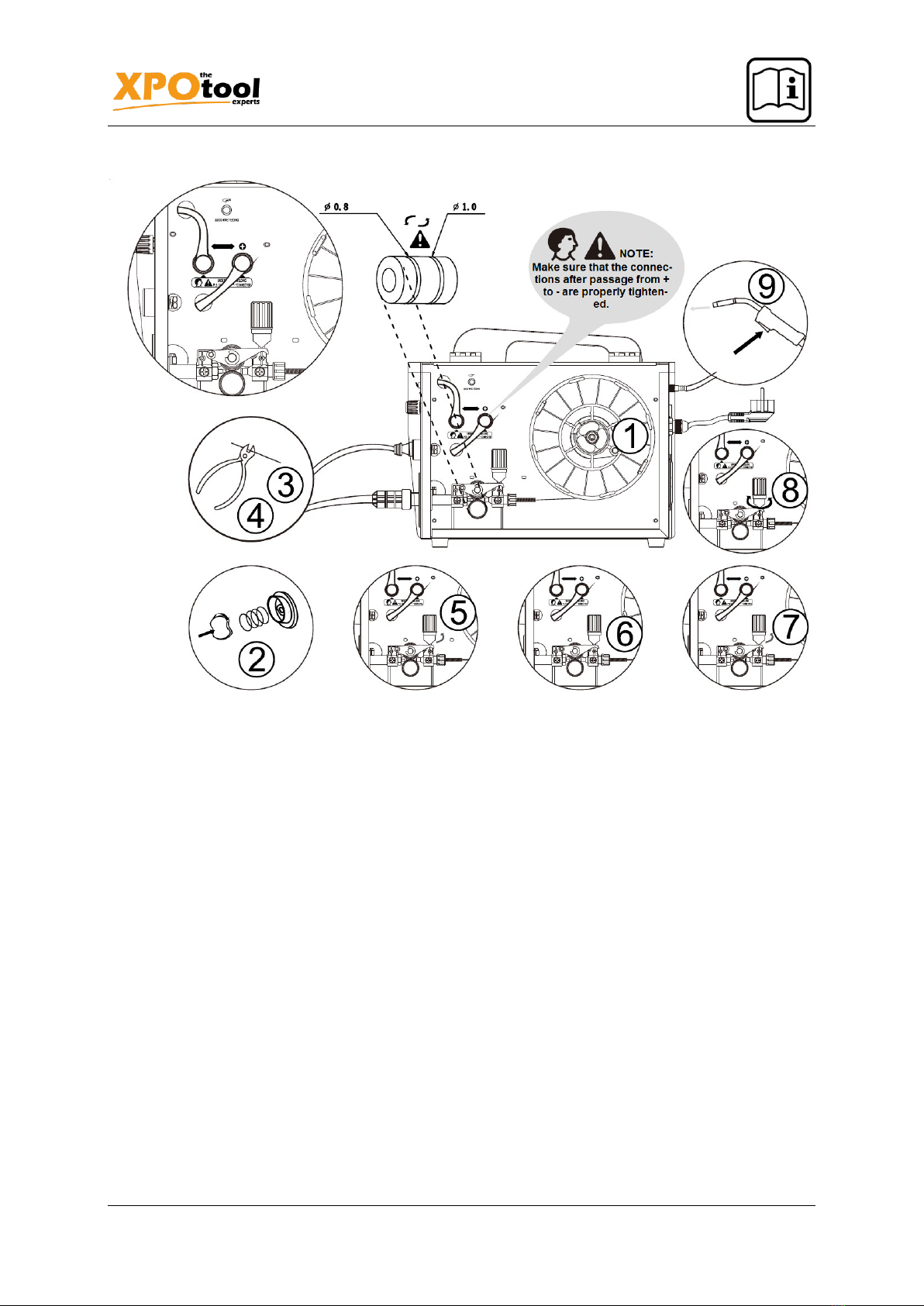

•The device welds best when the welding wire has a diameter of 0.8 mm. In addition, solid or

filler wire with a diameter of 0.6 mm, 0.9 mm, or 1.0 mm can be used as welding wire. However,

it should be noted that the device is only suitable for steel wire welding.

Welding

•The welding result does not only depend on the respective welding machine, but also on the

workpiece and the working environment. Therefore, the user must strictly follow the instructions

in this manual.

•During welding, electrical current is passed through the welding nozzle to the welding wire and

from there to the workpiece. An earth cable attached to the workpiece returns power to the

device, thereby completing the circuit. The current can flow unhindered if the earth clamp is

properly attached to the workpiece and the point at which the clamp rests on the workpiece is

clean, colourless, and rust-free.

•Shielding gas must be used for welding so that no air mixes with the weld. Carbon dioxide or a

mixture of carbon dioxide and argon is suitable as shielding gas. Some welding wires generate

shielding gas themselves, which is produced when the wire filling melts, which means that there

is no need to use an additional shielding gas.

Safety instructions

The device is safe to use as the plastic cover does not conduct electricity. The welding gun is equipped

with an overheating protection that prevents the device from becoming excessively hot. It also has a

protection from too low or too high input voltage. Nevertheless, numerous dangers can arise from weld-

ing work, and it is imperative that you read the safety instructions carefully and follow them.

Protective equipment

•Do not look into the arc with unprotected eyes, only use a welding protection shield with protec-

tive glass in accordance with DIN. The welding shield must always be used during welding. It

protects your eyes from harmful UV rays and heat from the electric arc.

•The arc and weld spatter cause burns to the skin. Therefore, always wear protective gloves and

clothing when welding.

•When working with a higher setting, also wear a leather apron to protect yourself from welding

spatter.