265

Prado

Road,

Suite

1

|

San

Luis

Obispo,

CA

93

401

|

805.541

.0100

|

xpress

fill.com

|

[email protected]10 | XpressFill Systems LLC

4

Operating Procedures

Step By Step

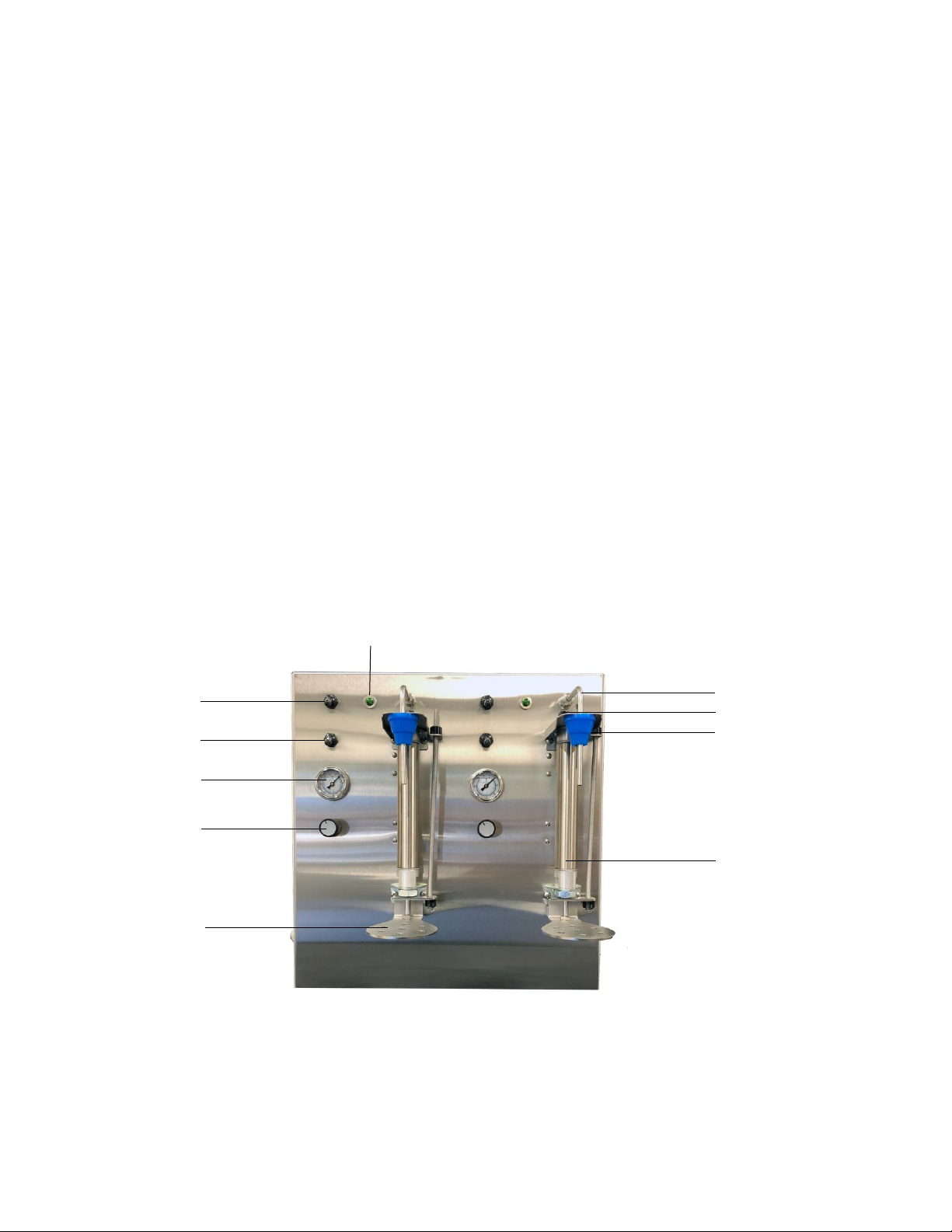

1. You will first want to unpack your filler from the

shipping box and spread the components out on a

large flat surface. Make sure that you also have the

following:

a. Pressurized CO2 tank with regulator and

connecting hosing (we recommend a wye as well,

see setup diagram for details).

b. Air compressor and 1/4" hosing

c. A small (.5 liter or so) catch container for

collecting vented liquid.

2. Place your filler on a flat surface where you plan to

bottle, ensuring that you have access to a standard

wall outlet or extension cord. Some type of surge

protection / power conditioner is recommended.

Place the liquid and CO2 tanks, as well as the air

compressor, nearby. Attach the support legs by

sliding the legs between the enclosure and the rubber

feet. The support legs should extend forward,

however if you extend them out the back you need to

clamp them to the flat surface.

3. Begin by plugging the provided power cord into your

machine, and then plug it into the wall. Now is a

good time to make sure that when you turn the

machine on, the green power switch lights up

4. Once you are sure that you have power to the

machine, flip all switches to their down or off

position. This includes all Fill Switches and all

Pressure Release Switches.

5. Plug the hose from your liquid container into the

port marked “Inlet” on the left side of the machine

using one of the provided 3/8” barbed fittings. See

“Adjusting Pressures” on page 11.

6. Plug one end of the provided 4’ x 1/4” hose into

the port marked “Vent” on the left side of the

machine, and place the other end into your catch

container.

7. Plug your air compressor into the port marked

“Air” on the left side of the machine using one of

the provided 1/4” barbed fittings. See “Adjusting

Pressures” on page 11.

8. Plug your CO2 tank into the port marked “CO2”

on the left side of the machine using one of the

provided 1/4” barbed fittings.

9. Once you are sure that all components are plugged

in correctly, you can open the valves on your tanks

and turn the air compressor on.

10. Turn on your machine by flipping the power

switch on the right side of your machine so that it

is lit up.

11. You are now ready to place a bottle on your

machine. While pressing down on the Bottle Foot

Rest, place a bottle on the Bottle Foot Rest and

allow the Bottle Foot Rest to lift the bottle towards

the stopper. The bottle does not seal yet, let it rest

in place near the stopper.

It is highly recommended that water be used during the initial set up procedure. Water allows you to familiarize

yourself with the filler by removing most variables related to your product, for ease of operation, and the

reduction of waste of your product.