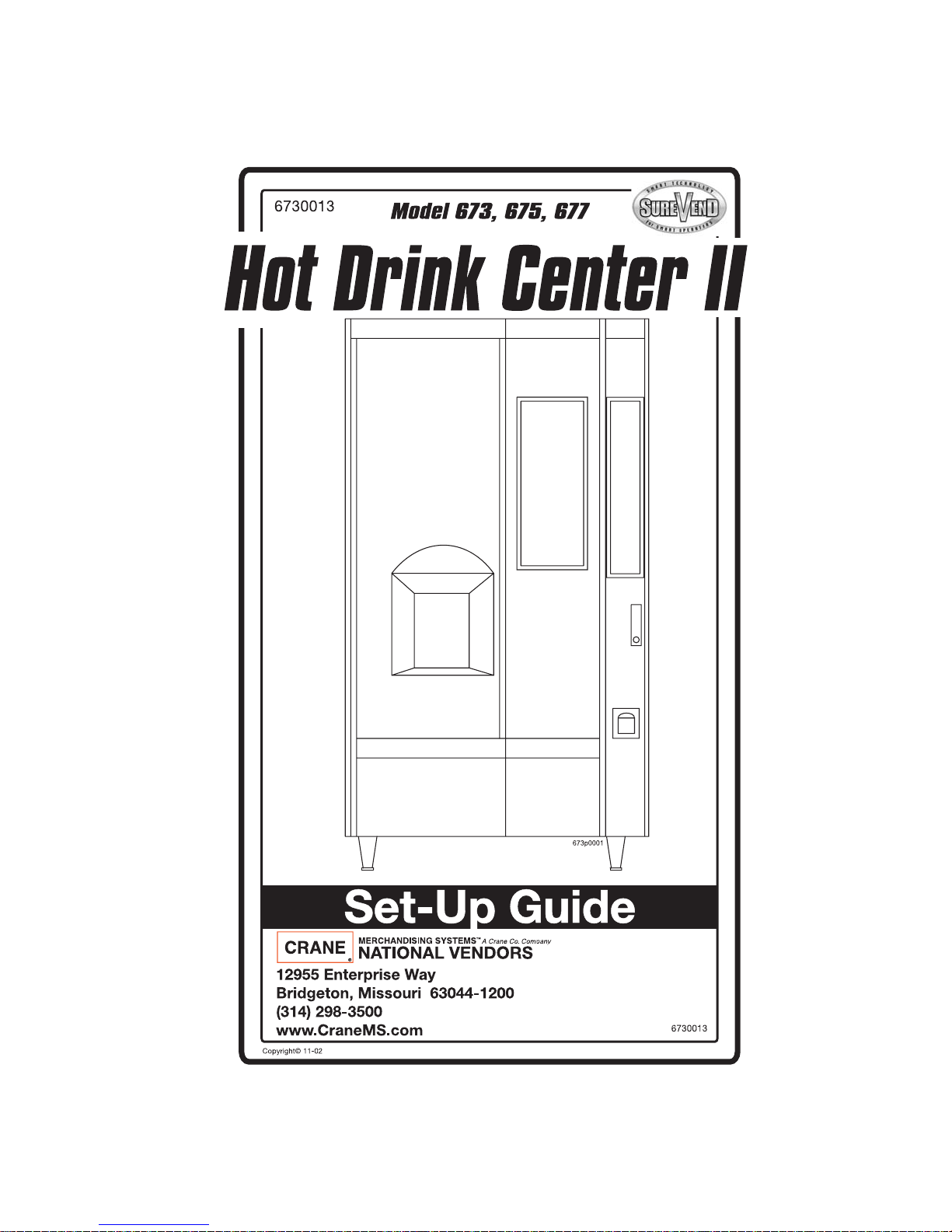

Hot Drink Center II Set-Up Manual

6730013 i

February, 2003

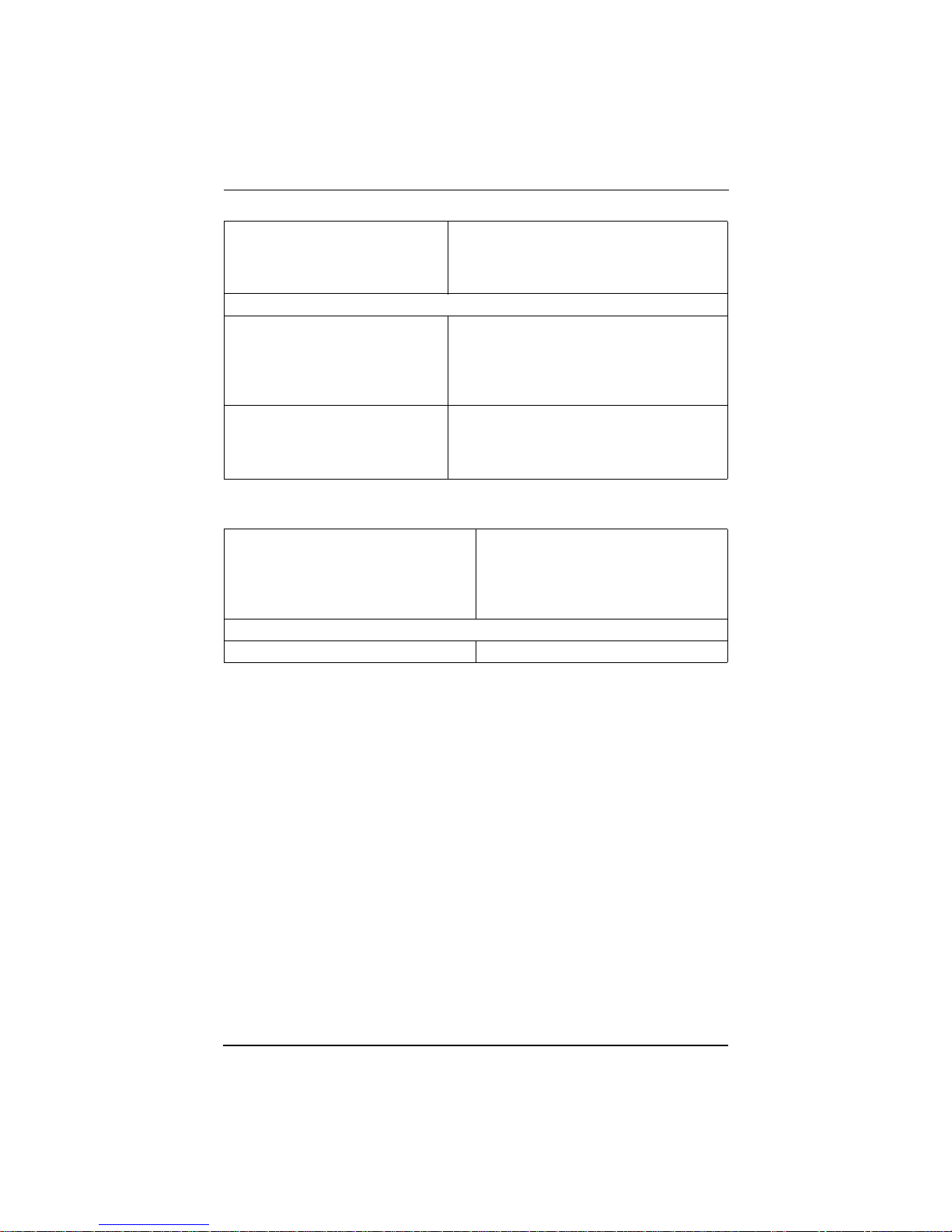

Table of Contents

Title Page

SPECIFICATIONS............................................................................................ 1

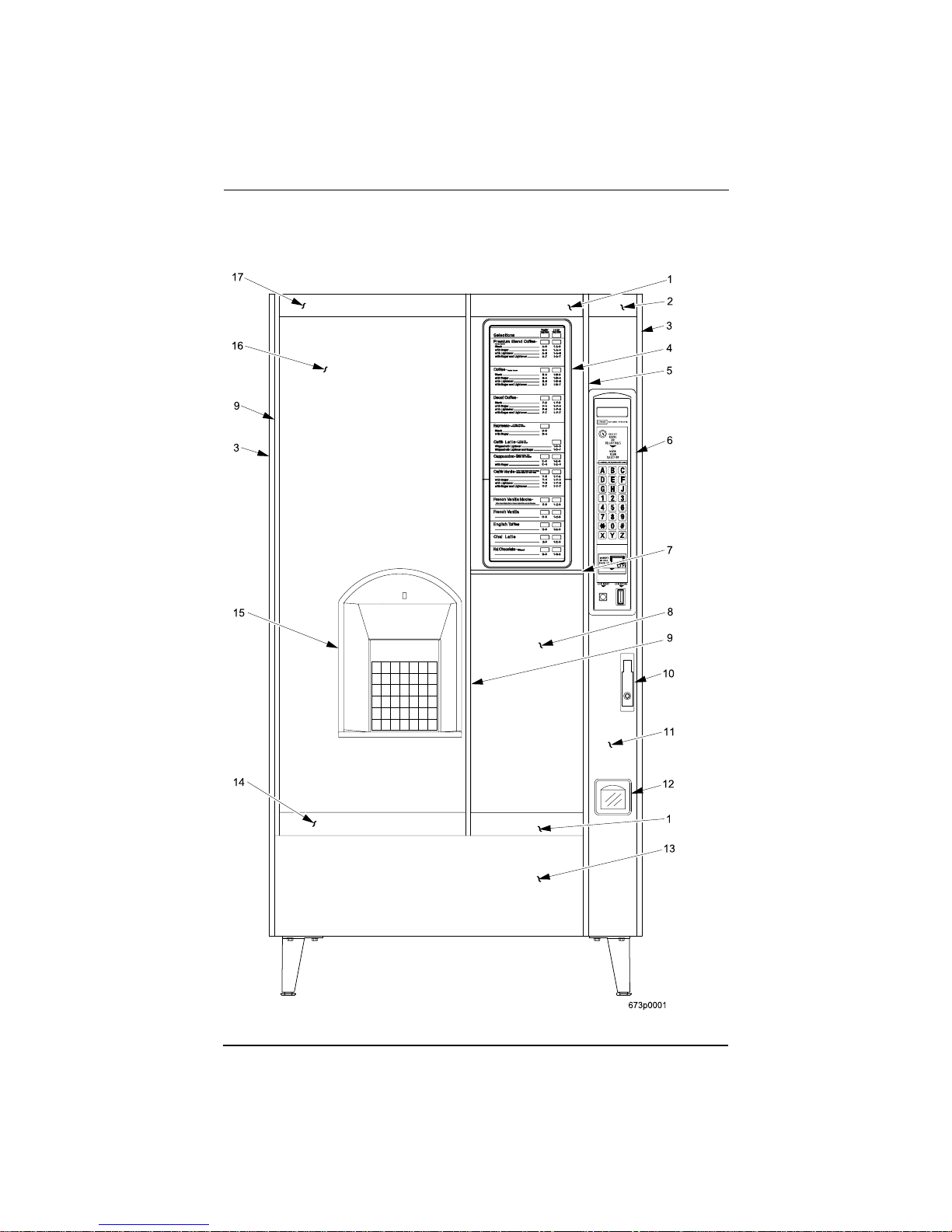

MAJOR PARTS ................................................................................................. 4

CONTROLS AND INDICATORS ................................................................... 8

INITIAL SET-UP ............................................................................................. 14

Location Preparation ................................................................................... 14

Water Requirements ................................................................................ 15

Positioning the Merchandiser...................................................................... 16

Connecting Everything................................................................................ 16

Connect the Merchandiser to the Water Supply: ................................. 16

Connect the Merchandiser to the Electrical Power Supply: ................ 16

Final Mechanical Preparation...................................................................... 16

Level the Merchandiser:....................................................................... 16

Mount the Base Plate: .......................................................................... 17

Set Up the Menu Assembly ................................................................. 18

Install the Water Filter Cartridge: ........................................................ 19

Load the Optional Filter Paper:............................................................ 22

Install the Optional Coin Box Lock ..................................................... 24

Load the Coin Mechanism ................................................................... 24

Fill the Tank:........................................................................................ 24

Fill the Canisters: ................................................................................. 25

Load Cups: ........................................................................................... 26

Tell the Machine About the Cup Size(s):............................................. 27

Test the Machine:................................................................................. 28

ADJUSTMENTS AND MINOR MAINTENANCE...................................... 29

Water Valve Adjustment............................................................................. 29

Cup Mechanism Adjustment....................................................................... 30

Grinder Adjustment..................................................................................... 31

Disengaging the Grinder ............................................................................. 32

Canister Installation..................................................................................... 32

Removing POP to Service fluorescent lights, Starters and ballasts............ 33

SANITATION................................................................................................... 34

Basics .......................................................................................................... 34

Clean the Hot Water Tank........................................................................... 36

Sanitation Procedures.................................................................................. 36

Food-Contact Parts .................................................................................. 36

Non Food-Contact Parts .......................................................................... 37

Brewer Cleaning.......................................................................................... 38

Overall Cleaning ......................................................................................... 44

Preventive Maintenance Cleaning............................................................... 44