IMPORTANT SAFETY INFORMATION

2

People with pacemakers should consult their physician(s) before use. Electromagnetic elds in close

proximity to a heart pacemaker could cause pacemaker interference or pacemaker failure. Caution is

necessary when near the generator’s magneto or recoil starter.

Use only accessories that are recommended by XtremePowerUS for your model. Accessories that may

be suitable for one piece of equipment may become hazardous when used on another piece of equipment.

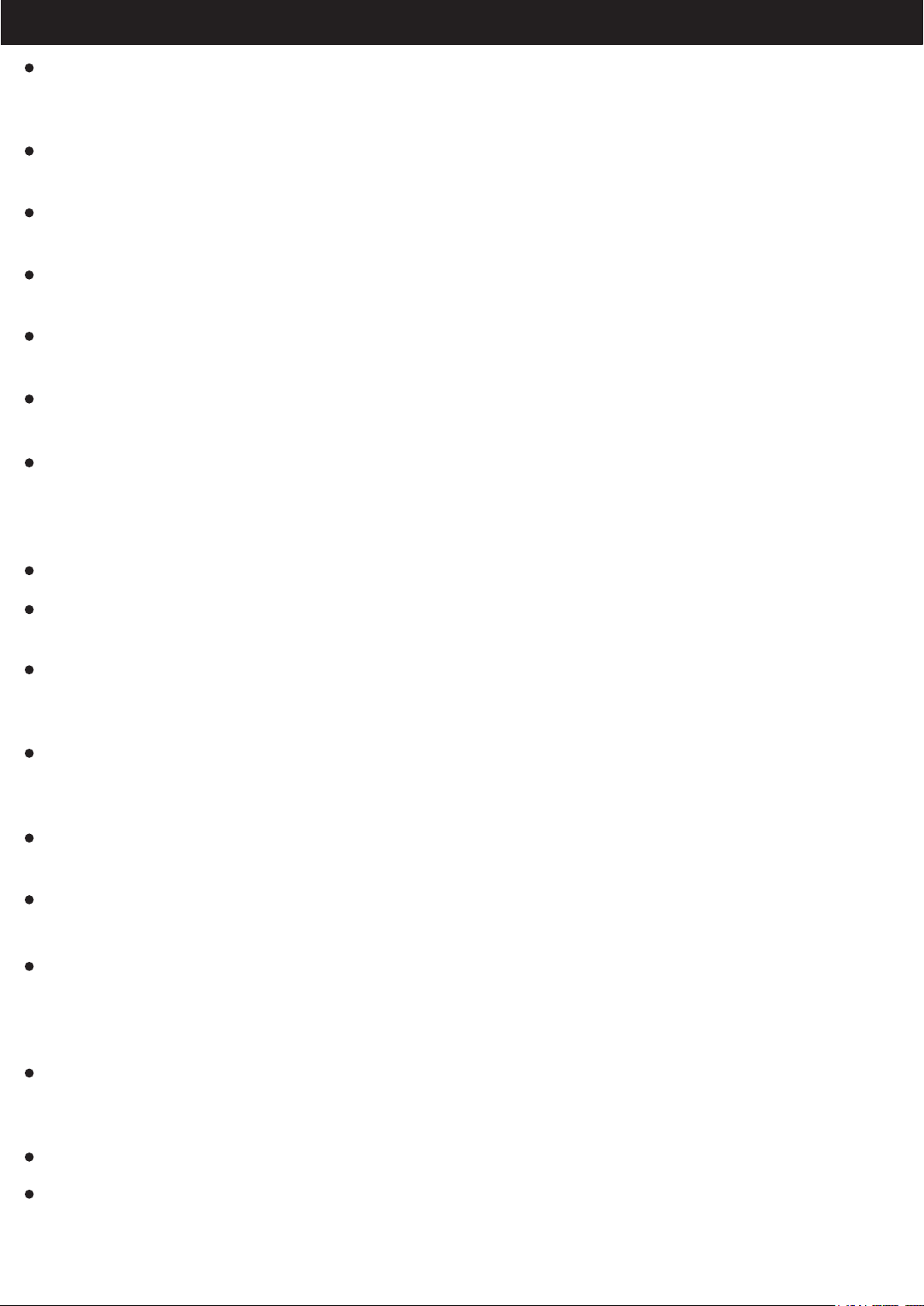

DO NOT operate in explosive atmospheres, such as in the presence of ammable liquids, gases, or dust.

Gasoline-powered generators may ignite the dust or fumes.

Stay alert, watch what you are doing and use common sense when operating this piece of equipment.

DO NOT use this piece of equipment while tired or under the inuence of drugs, alcohol or medication.

DO NOT overreach. Keep proper footing and balance at all times. This enables better control of the

equipment in unexpected situations.

Dress properly. DO NOT wear loose clothing or jewellery. Keep hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

Use the equipment, accessories, etc., in accordance with these instructions and in the manner intended

for the particular type of equipment, taking into account the working conditions and the work to be

performed. Use of the equipment for operations different from those intended could result in a hazardous

situation.

DO NOT operate the equipment with known leaks in the Generator’s fuel system.

This product contains or, when used, produces a chemical known to the State of California to cause

cancer and birth defects or other reproductive harm. (California Health & Safety Code § 25249.5, et seq.)

When spills of fuel or oil occur, they must be cleaned up immediately. Dispose of uids and cleaning

materials as per any local, state, or federal codes and regulations. Store oil rags in a bottom ventilated,

covered, metal container.

Before use, check for misalignment or binding of moving parts, breakage of parts, and any other condition

that may affect the equipment’s operation. If damaged, have the equipment serviced before using. Many

accidents are caused by poorly maintained equipment.

Use the correct equipment for the application. DO NOT modify the equipment and do not use the

equipment for a purpose for which it is not intended.

FIRE HAZARD! DO NOT ll fuel tank while generator is running. DO NOT operate if gasoline has been

spilled. Clean spilled gasoline before starting generator. DO NOT operate near pilot light or open ame.

This unit is to be installed so that access is restricted to only qualied service personnel who have been

instructed of the reasons for the restrictions applied to the location and about any precautions that must

be taken. Access shall be through the use of a special tool, or lock and key, or other means of security

and shall be controlled by the authority responsible for the location.

Operation of this equipment may create sparks that can start res around dry vegetation. A spark arrestor

may be required. The operator should contact local re agencies for laws or regulations relating to re

prevention requirements.

Use only lubricants and fuel recommended in the Specications chart of this manual.

WARNING: This product contains or, when used, produces a chemical known to the State of California to

cause cancer and birth defects or other reproductive harm. (California Health & Safety Code § 25249.5,

et seq.)