Greenlee Textron / Subsidiary of Textron Inc. 94455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

HG3505A / 42303 Portable Power Unit

Operation (cont’d)

IMPORTANT

Position the power unit on firm level ground.

Pre-Start

1. Check the engine oil level. Refer to the engine

Operating and Maintenance Instructions for the

correct oil type and checking instructions.

2. Check the fuel level. Operating and Maintenance

Instructions for the fuel recommendation.

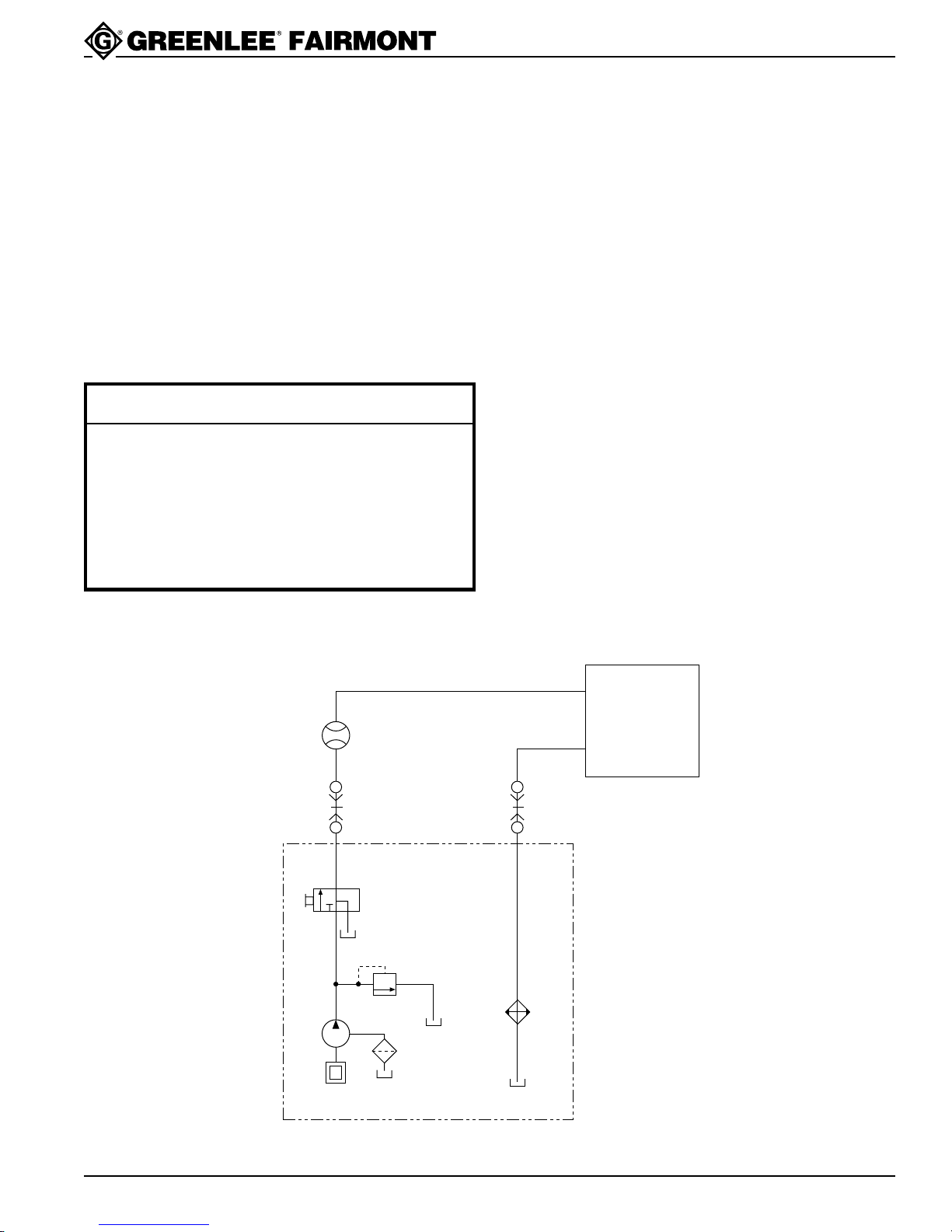

3. Check the hydraulic reservoir oil level. The hydraulic

oil should appear in the lower 1/4 of the sight

gauge.

4. Verify that all current maintenance has been per-

formed on the power unit. See Maintenance.

Connect the tool hoses and tool to the power unit.

See Hose Connections.

Starting the Power Unit

1. Pull the red bypass valve on the reservoir UP.

2. Set ignition switch to the ON position, and throttle

lever to the START position.

3. Before pulling starter cable, set choke lever to the

CLOSED position if engine is cold, or to HALF

OPEN position if engine is warm.

4. Pull starter cable slowly until some resistance is felt.

Return to starting position, then pull starter cable

out quickly.

Note: If the engine does not start after three attempts,

set choke lever to the OPEN position, to avoid

flooding the engine. Be sure the ignition switch is

in the ON position, and throttle lever is in START

position.

5. After the engine has started, return the choke lever

to the OPEN position, and allow the engine to warm

up for 3-5 minutes without moving the throttle lever.

The efficiency of any hydraulic unit will be reduced

in cold weather if the unit is operated with cold oil.

It is recommended that the power unit be allowed to

warm up before operating any tool.

6. After the engine is warmed up, engine speed can be

controlled by the throttle lever. Move the throttle

lever up, running the engine at full speed.

7. To direct oil to the tool, push the red bypass valve

on the reservoir DOWN.

Stopping Procedure

1. Pull red bypass valve on the reservoir UP to stop

the flow of oil to the tool.

2. Move the throttle lever DOWN to idling speed. Allow

the engine to idle for a moment. Turn ignition switch

to the OFF position.

Note: Do not store unit with fuel in the tank for long

periods of time. Refer to storage procedure in

Kawasaki Engine Service Manual.

Emergency Stopping

In case of an emergency, such as a fire, stop the engine

immediately by turning the ignition switch to the OFF

position.

Lifting the Power Unit

Use appropriate lifting equipment. Make sure all

components used to lift this power unit are rated for

100 lbs (46 kg) and are securely attached between

the power unit and lifting equipment. Inadequate

components may fail and cause the power unit to

fall, resulting in injury or property damage.

Stop the power unit engine before lifting. Take care

when attaching the lifting device (chain, strap, etc.) to

the lifting eye so as not to damage the power unit.