— 4 —

Introduction

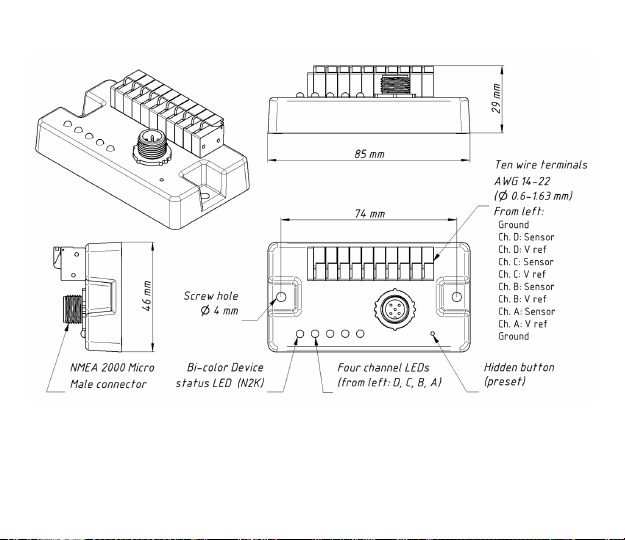

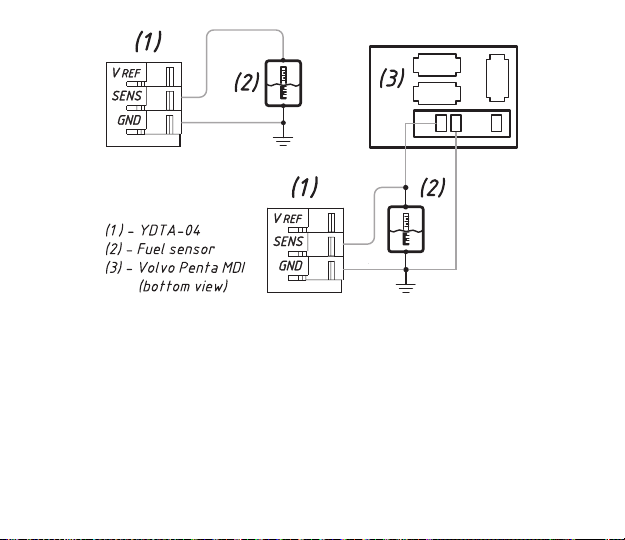

The NMEA 2000 Tank Adapter YDTA-04 (hereinafter Adapter or Device) allows you to connect an existing

resistive or voltage-output type uid level sensor installed on a tank and display the uid level on NMEA

2000 devices, including chart plotters and instrumental displays.

The Adapter can be congured to report one of the 15 uid types dened in the NMEA 2000 standard,

including Diesel Fuel, Gasoline Fuel, Oil, Fresh Water, Waste Water, Black Water (Sewage), or Live Well.

The Device can be used with European (10 to 180 Ohm range), American (240 to 33 Ohm range) or Japanese

(0 to 310 Ohm range) standard uid level sensors as well as with any nonstandard sensors with maximum

resistance less than 400 Ohm. The Device can also be used with uid level sensors, which output an analog

voltage signal in the range of 0 to 16 Volts.

The Adapter can be installed as a standalone measuring device, in parallel with an existing analog gauge

(2-coils and 1-coils gauges are supported), or in parallel with a Volvo Penta engine’s MDI (Mechanical Diesel

Interface) box. The four measuring channels of the Device may have individual settings. Fluid tank level

sensor readings can be calibrated with 12 calibration points to get accurate readings on tanks of any shape.

The Adaptor can switch the load channels of NMEA 2000 digital switching equipment on or o. Up to eight

dierent conditions for each measuring channel can be used.

Firmware updates are available only with Yacht Devices gateways (Wi-Fi, USB or Ethernet), see Section

VIII for details.

The Device is powered from the NMEA 2000 network and provides high voltage galvanic isolation between

NMEA 2000 and sensor inputs.

We thank you for purchasing our Devices and wish you happy voyages!

The Device is equipped with a hidden button that allows switching among 15 conguration

presets (see Section V). However, for advanced conguration (calibration curves, digital

switching functions, connection in parallel with analog gauges, using voltage sensors)

the NMEA 2000 PC gateway (from any manufacturer) or MFD which allows editing of

installation description strings (see Section VI) is required.