TO CO2 Gas Sensing Evaluation Kit (Analog) USEQGCK5000000

The above information is believed to be correct but does not purport to be all inclusive and must be used only as a guide.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com 2

TABLE OF CONTENTS

1 INTRODUCTION ........................................................................................................... 3

2 GETTING STARTED ..................................................................................................... 3

2.1 Kit Contents............................................................................................................3

2.2 Minimum System Requirements .............................................................................3

3 INSTALLATION ............................................................................................................. 4

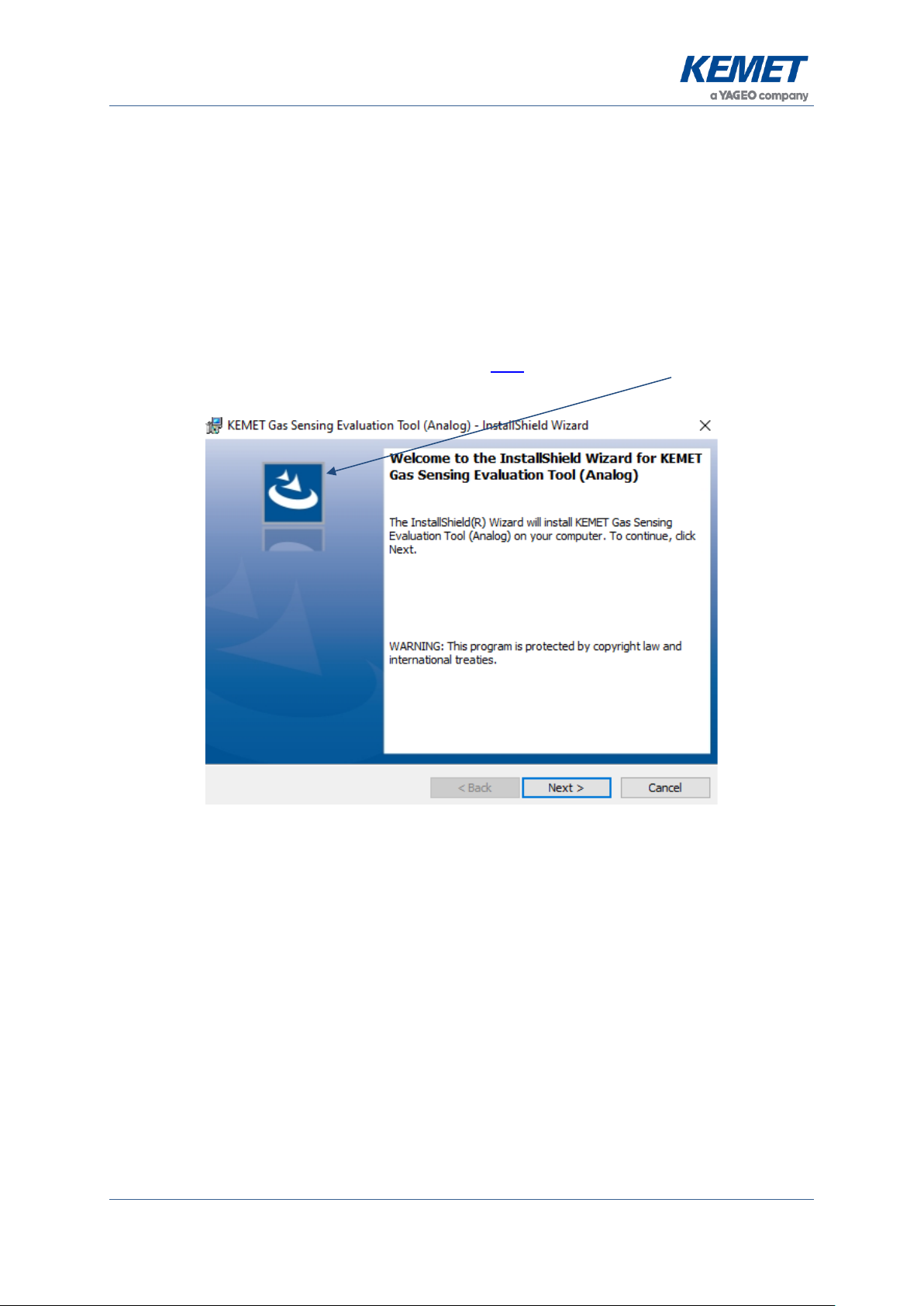

3.1 Installing the KEMET Gas Sensing Evaluation Tool Software.................................4

3.2 Connecting the TO Gas Sensing Evaluation Kit......................................................4

4 SOFTWARE USER GUIDE............................................................................................ 5

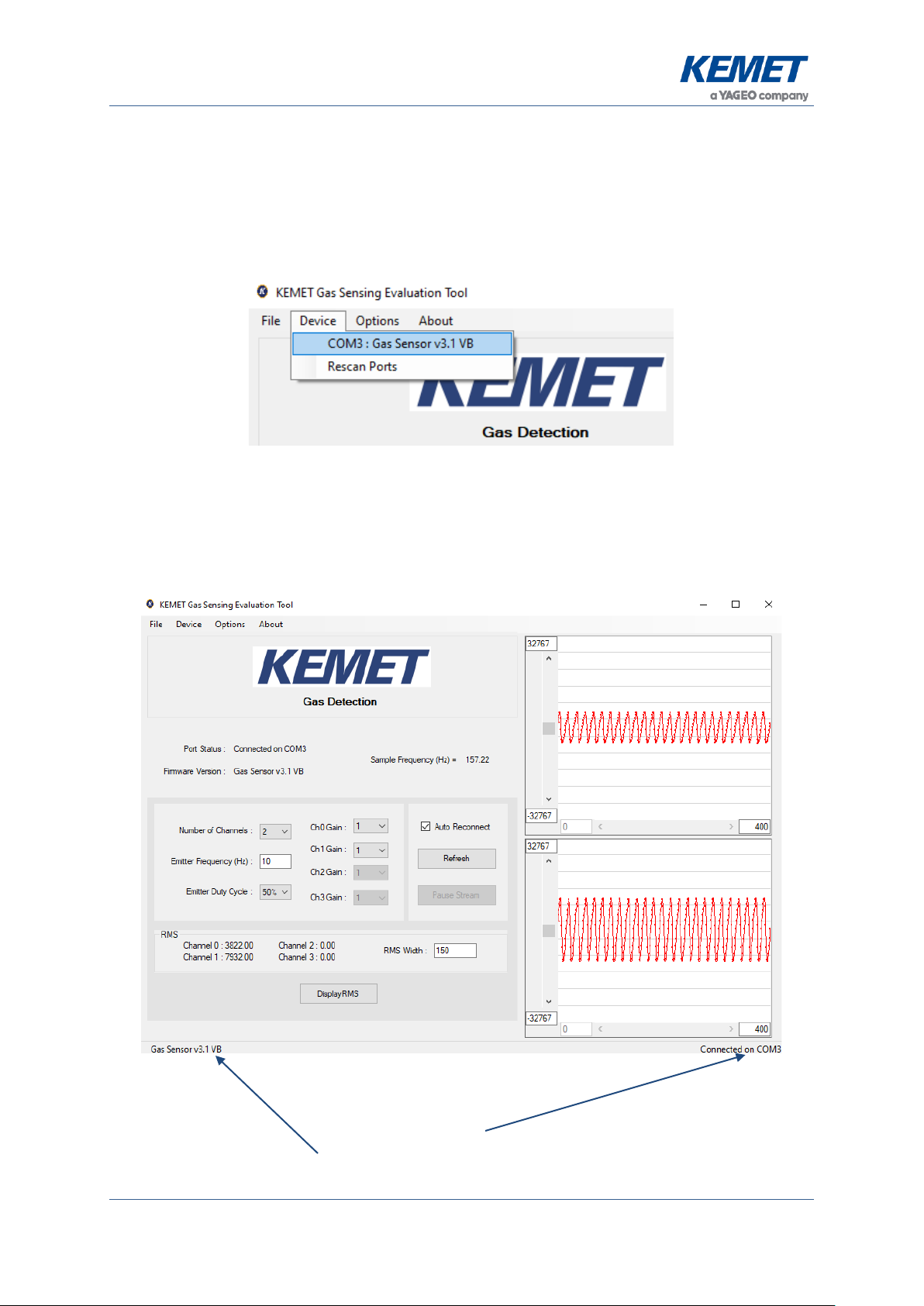

4.1 Starting the Software ..............................................................................................5

4.2 Connecting Software to the Data Capture Board ....................................................6

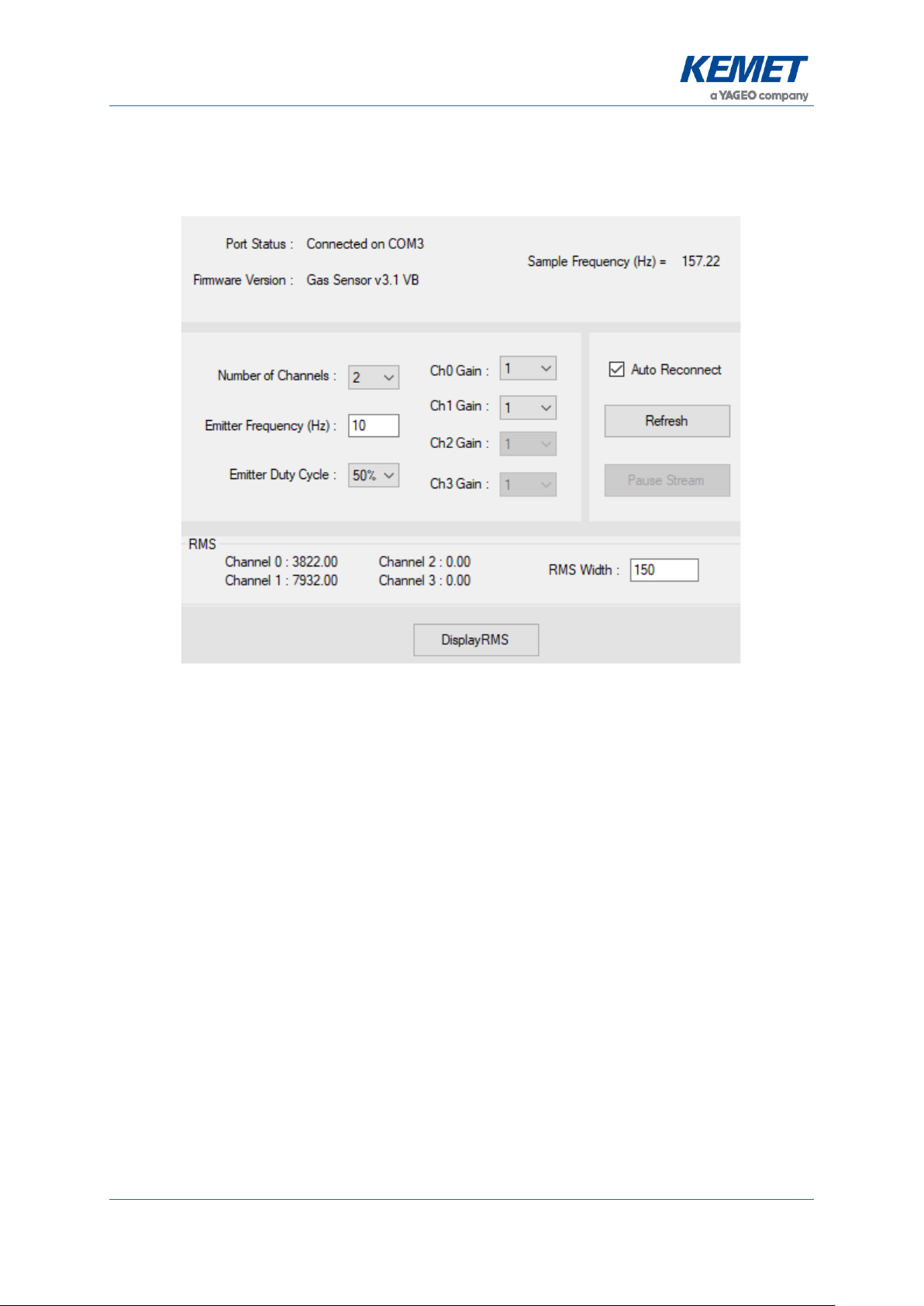

4.3 Data Capture Board Control....................................................................................7

4.3.1 Data Capture Settings ................................................................................7

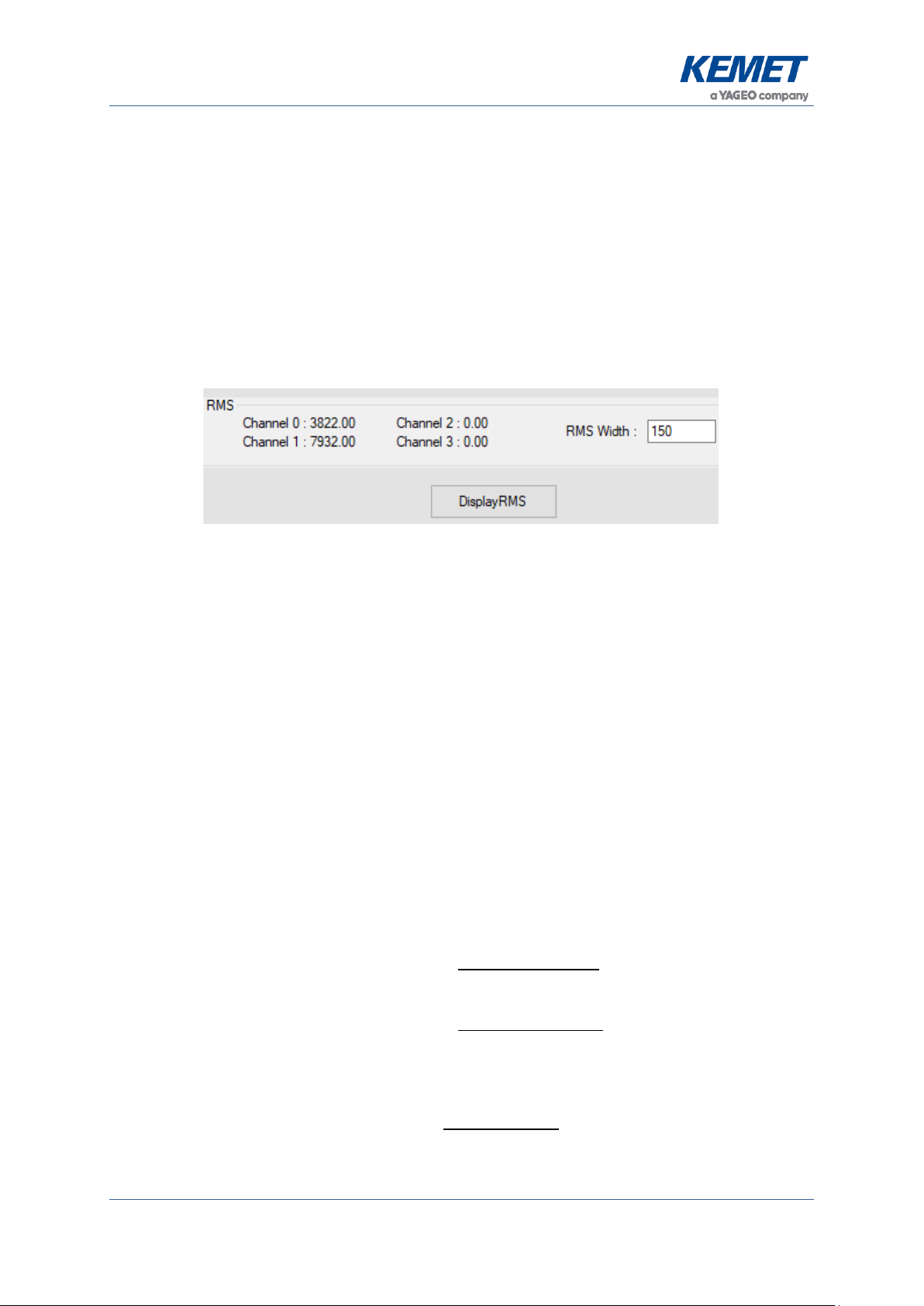

4.3.2 RMS Values................................................................................................8

4.3.3 RMS Width Value .......................................................................................8

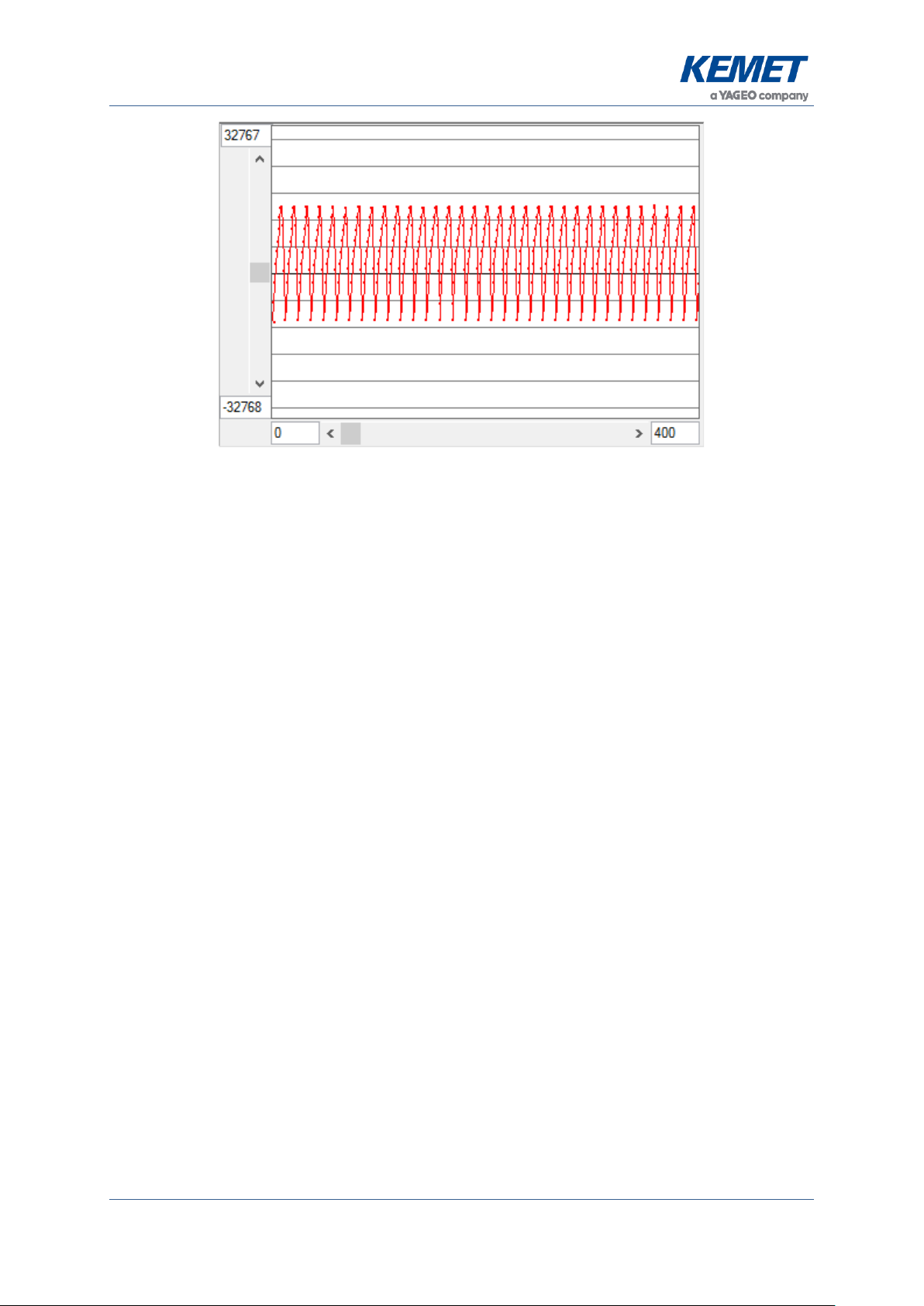

4.4 Viewing Live Data –Oscilloscope Window..............................................................9

4.5 Saving Data to CSV (Comma Separated Value) File..................................................11

5 CONCENTRATION VIEW............................................................................................ 12

5.1 Signal Processing.................................................................................................14

6 PC TO PCB COMMUNICATIONS................................................................................ 14

6.1 Commands Description.........................................................................................15

6.2 Sampling and Signal Processing for KEMET TO Sensors.....................................15

7 EMITTER VOLTAGE SETTING................................................................................... 17

7.1 Saturation of Signal...............................................................................................17

7.2 Method..................................................................................................................18