TABLE OF CONTENTS

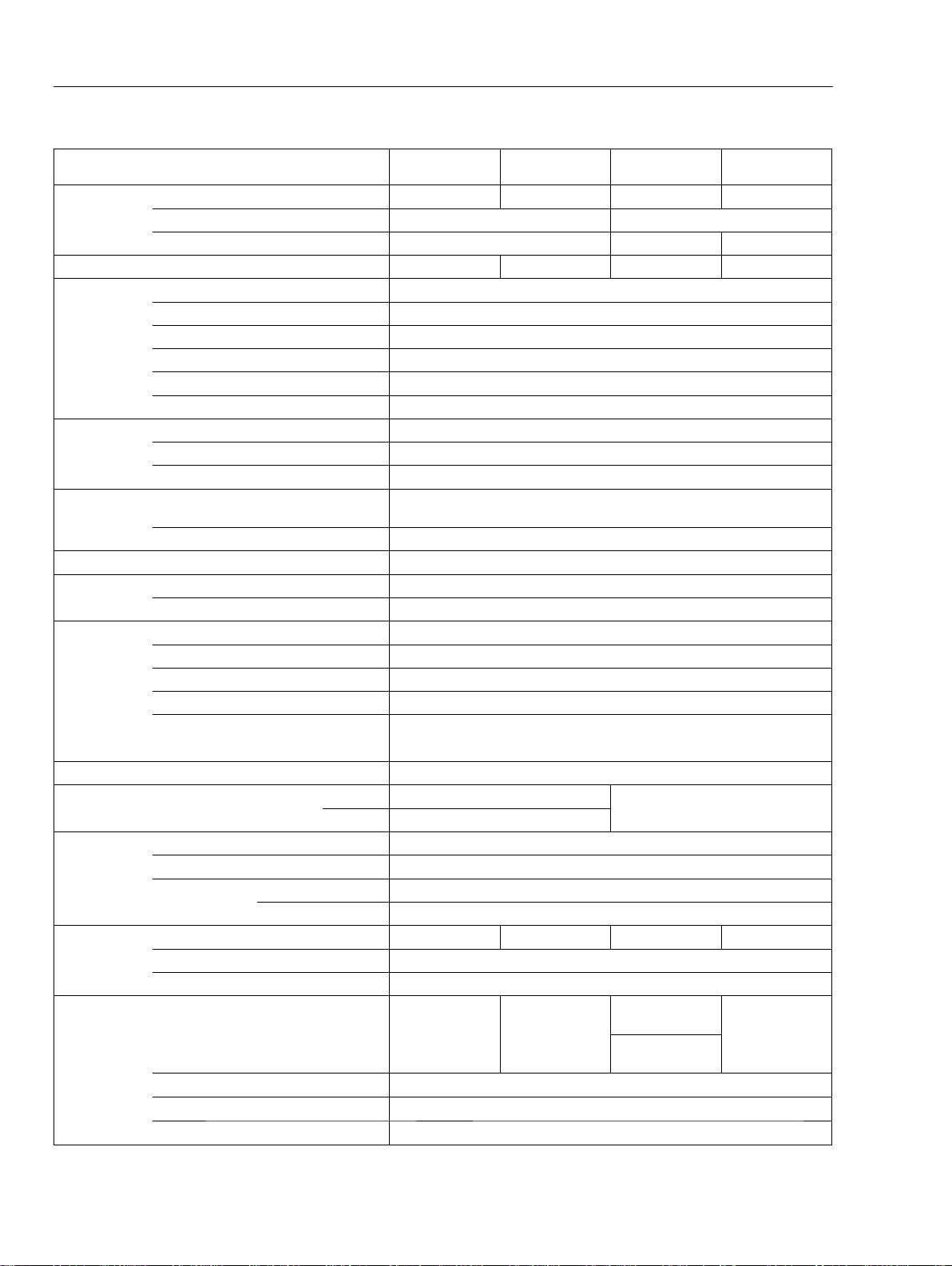

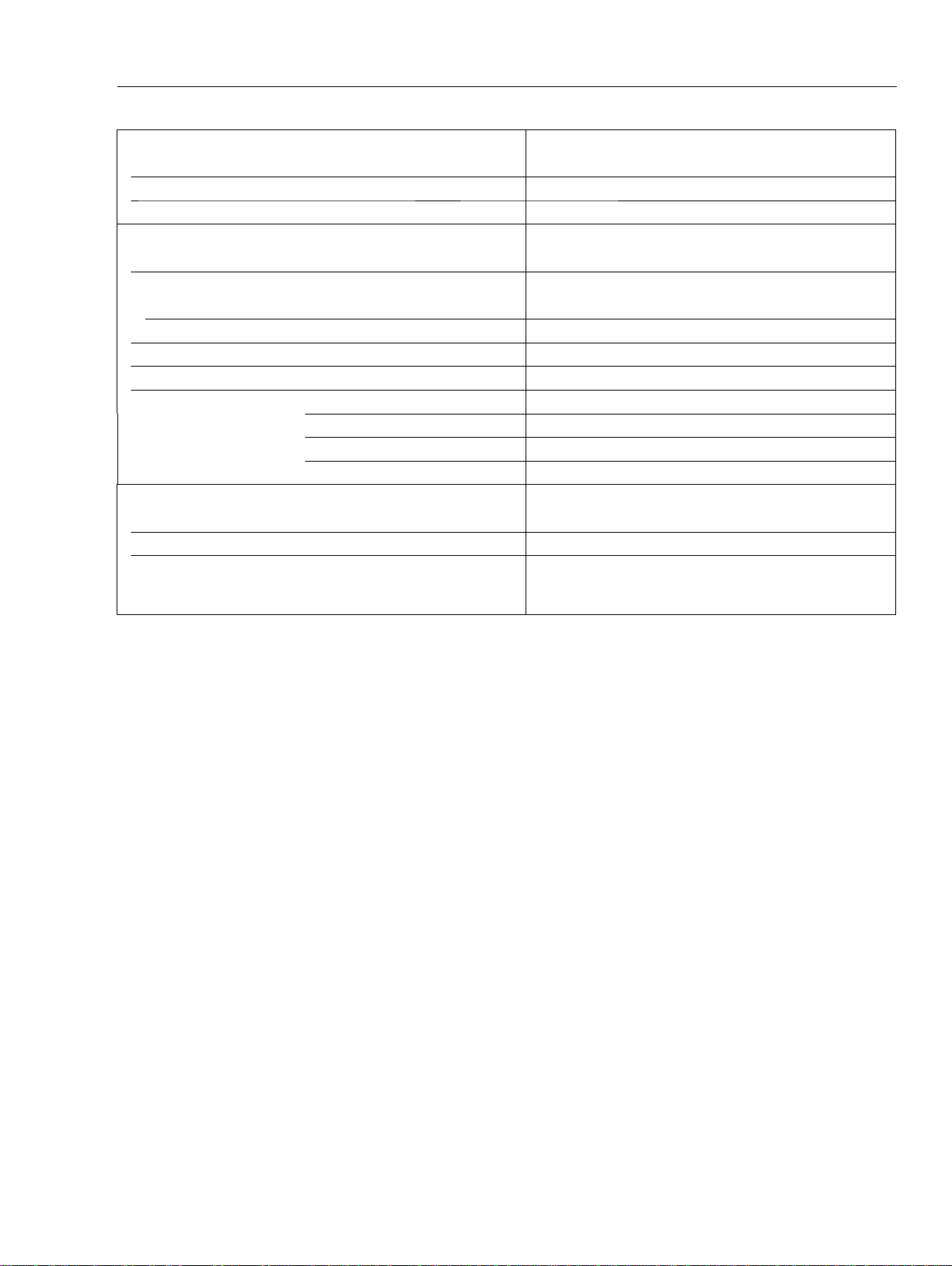

SRM-2620ES, SRM-2620TES

T262XS, C262S

T262TXS, C262TS 1

Page Page

1 SERVICE INFORMATION.....................................2

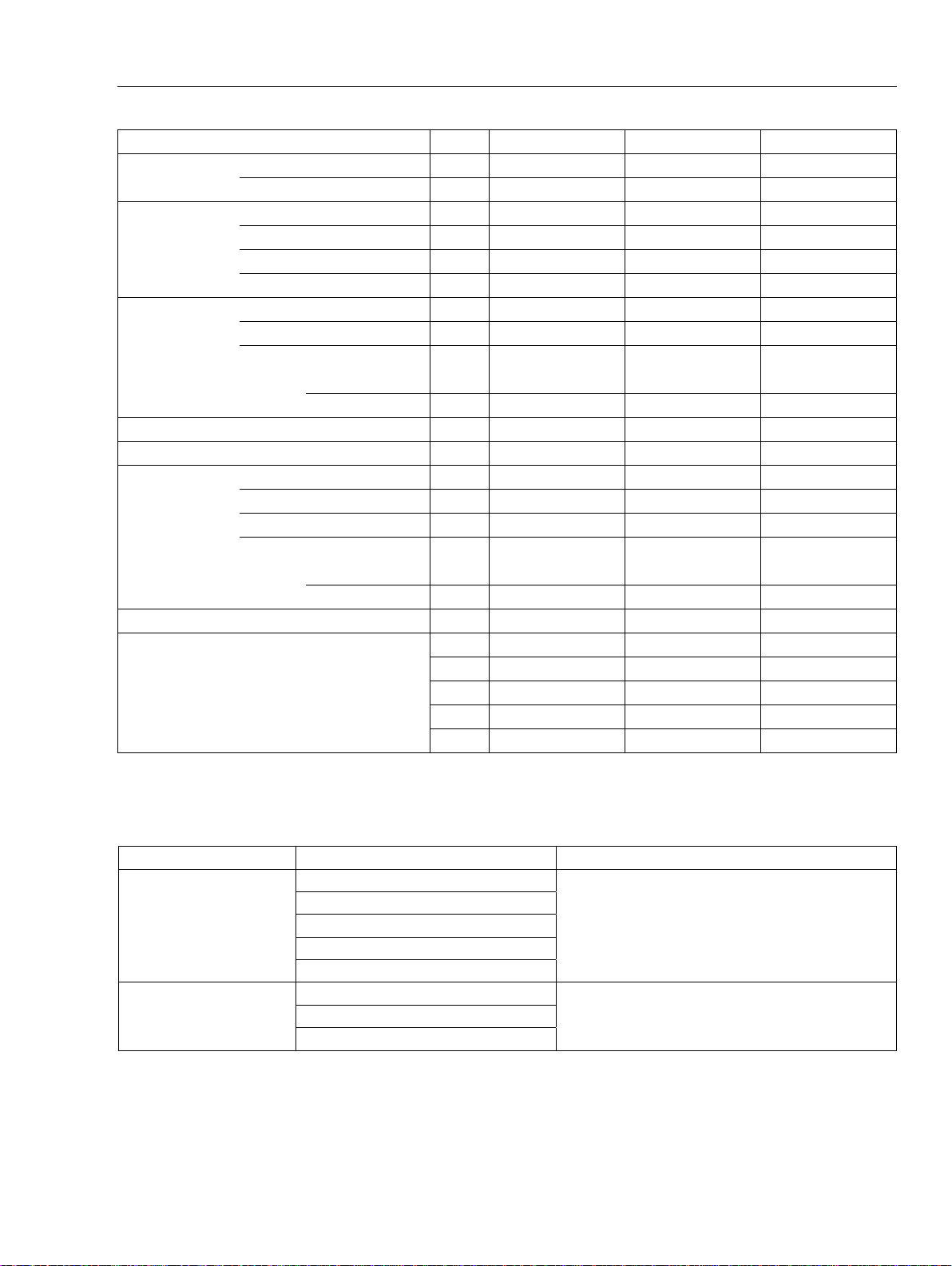

1-1 Specifications...................................................2

1-2 Technical data ..................................................3

1-3 Torque limits.....................................................5

1-4 Special repairing materials...............................5

1-5 Service limits....................................................6

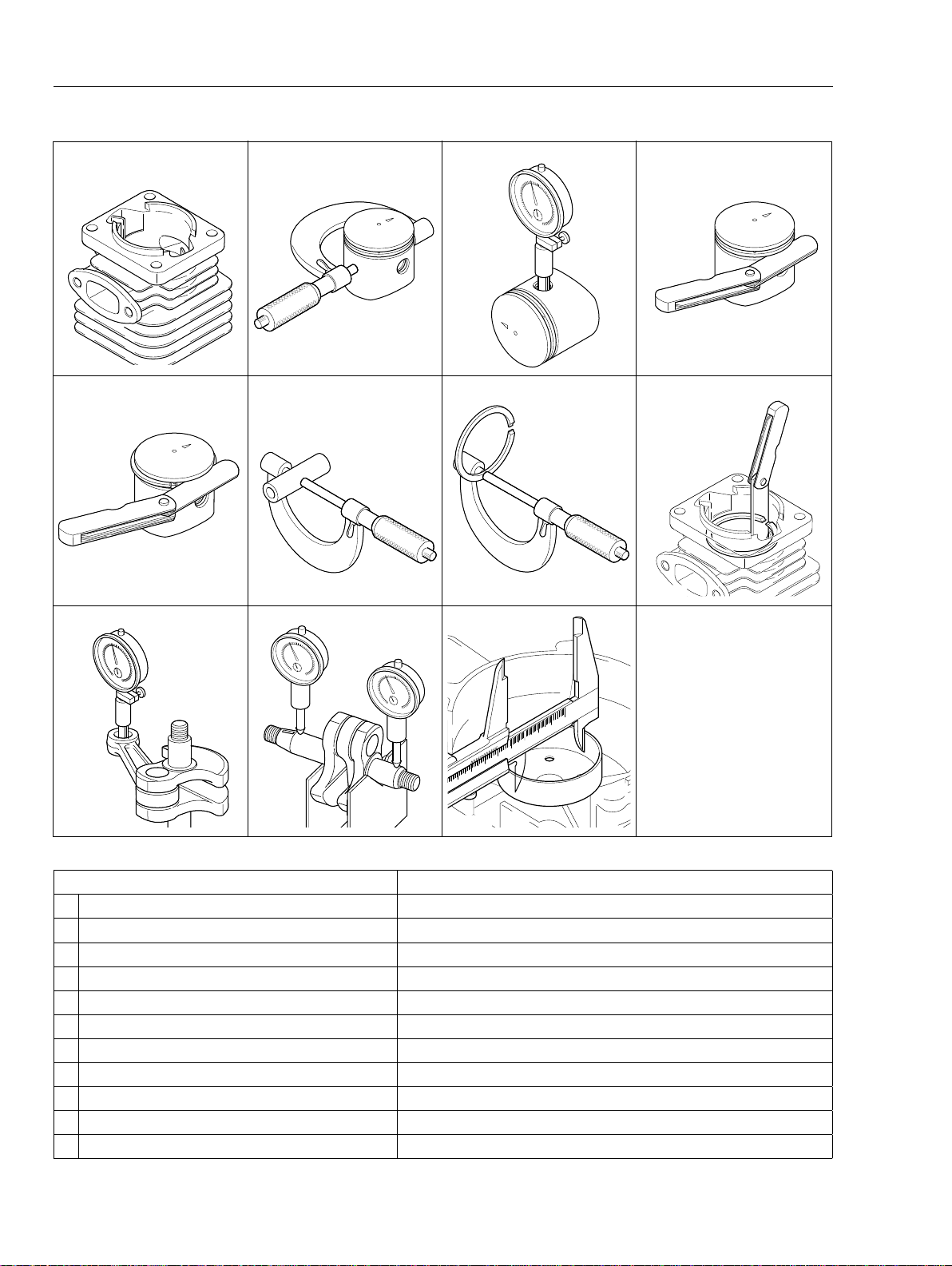

1-6 Special tools.....................................................7

2 STARTER SYSTEM..............................................8

2-1 Disassembling starter assembly.......................9

2-2 Replacing starter rope....................................10

2-3 Replacing rope guide .....................................12

2-4 Installing rewind spring...................................12

2-5 Assembling starter..........................................13

2-6 Replacing starter pawl....................................15

3 IGNITION SYSTEM.............................................17

3-1 Troubleshooting guide....................................17

3-2 Testing spark..................................................18

3-3 Inspecting spark plug .....................................18

3-4 Inspecting ignition switch................................19

3-5 Replacing ignition switch................................20

3-6 Inspecting ignition coil resistance...................23

3-7 Replacing spark plug cap and coil..................24

3-8 Replacing ignition coil.....................................24

3-9 Setting pole shoe air gaps..............................25

3-10 Inspecting flywheel and key ...........................25

4 FUEL SYSTEM ...................................................27

4-1 Cleaning air filter ............................................28

4-2 Checking fuel cap and fuel strainer................28

4-3 Inspecting fuel tank and tank vent..................29

4-4 Replacing fuel line, fuel return line, tank vent

line and grommet............................................30

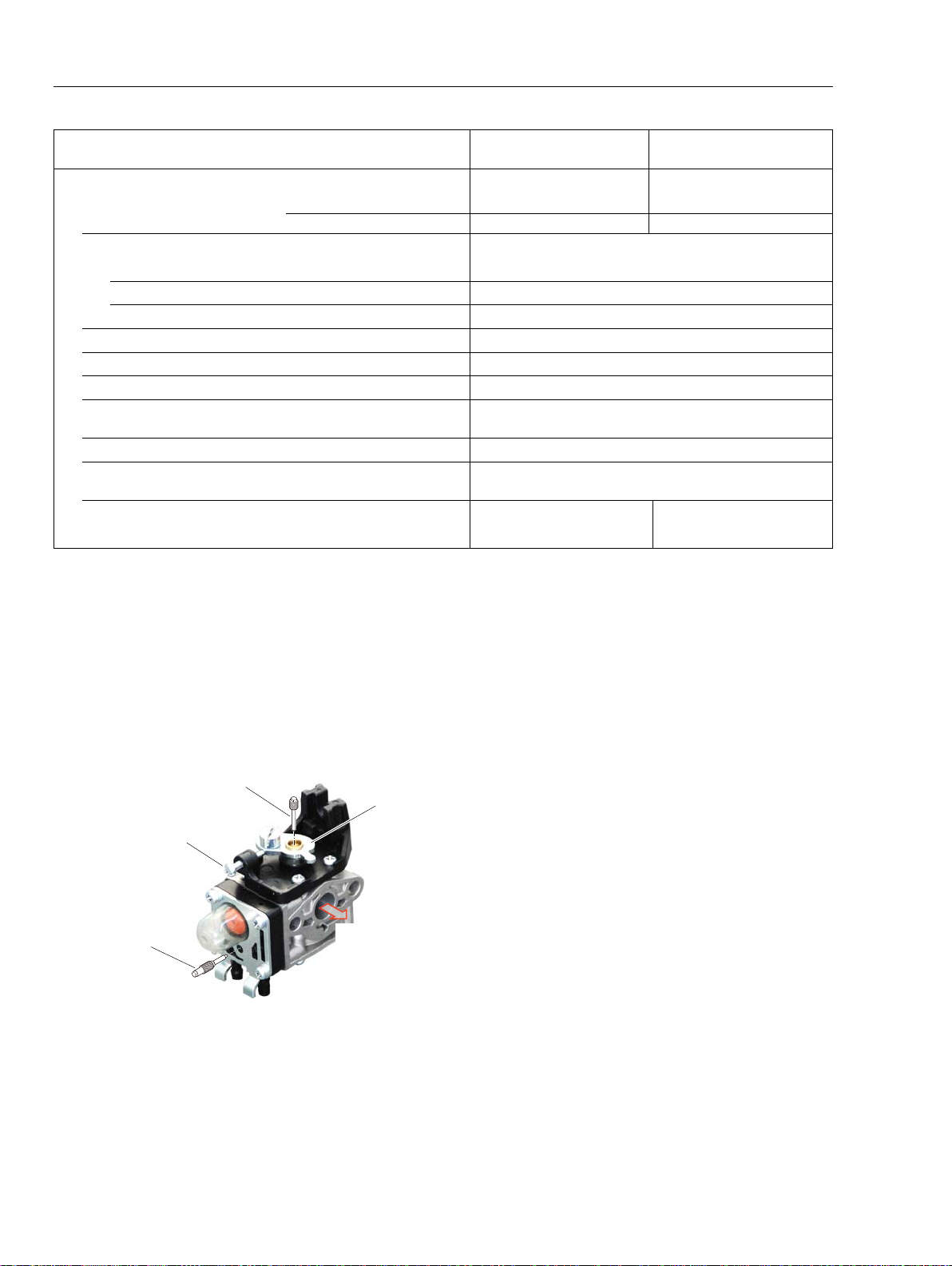

4-5 Adjusting carburetor.......................................32

4-5-1 General adjusting rules ..................................32

4-5-2 Initial setting Throttle adjust screw, L mixture

needle and H mixture needle ........................32

4-5-3 Adjusting carburetor.......................................33

4-6 Testing carburetor...........................................34

4-7 Inspecting crankcase pulse passage .............35

4-8 Inspecting metering lever height ....................35

4-9 Inspecting inlet needle valve..........................36

4-10 Inspecting diaphragm and others...................36

4-11 Replacing throttle cable and control parts......37

4-12 Checking and adjusting throttle cable ............37

5 CLUTCH SYSTEM..............................................38

5-1 Removing clutch shoes and springs...............39

5-2 Installing clutch shoes....................................39

5-3 Removing clutch drum....................................40

5-4 Removing clutch drum bearings.....................41

5-5 Installing bearings and clutch drum................41

6 ENGINE...............................................................42

6-1 Testing cylinder compression.........................43

6-2 Cleaning cooling air passages .......................43

6-3 Inspecting muffler and exhaust port...............44

6-4 Testing crankcase and cylinder sealing..........45

6-5 Removing and inspecting cylinder..................45

6-6 Inspecting piston and piston ring....................46

6-7 Replacing needle bearing...............................46

6-8 Inspecting crankcase and crankshaft.............47

6-9 Replacing oil seal...........................................47

6-10 Replacing ball bearing....................................48

6-11 Assembling crankshaft and crankcase...........48

6-12 Installing piston...............................................49

6-13 Installing piston ring and cylinder...................49

7 CUTTER DRIVE SYSTEM..................................50

7-1 Disassembling gear case...............................52

7-2 Replacing gears and PTO shaft.....................53

7-3 Assembling gear case....................................55

8 MAINTENANCE GUIDE......................................56

8-1 Service Intervals.............................................56

8-2 Disassembly Chart.........................................57

8-3 Troubleshooting guide....................................58