MDX-E300

2

MDX-E300

■TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked Z

and must be replaced with parts having specifications equal

to those originally installed.

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

●Meter impedance should be equivalent to 1500 ohm shunted

by 0.15µF.

●Leakage current must not exceed 0.5mA.

●Be sure to test for leakage with the AC plug in both

polarities.

AC LEAKAGE

TESTER OR

EQUIVALENT

EQUIPMENT

UNDER TEST

INSULATING

TABLE

WALL

OUTLET

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or

plastic (where applicable) components may also contain traces of chemicals found by the California Health and

Welfare Agency (and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR

ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes

or expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands

before handling food.

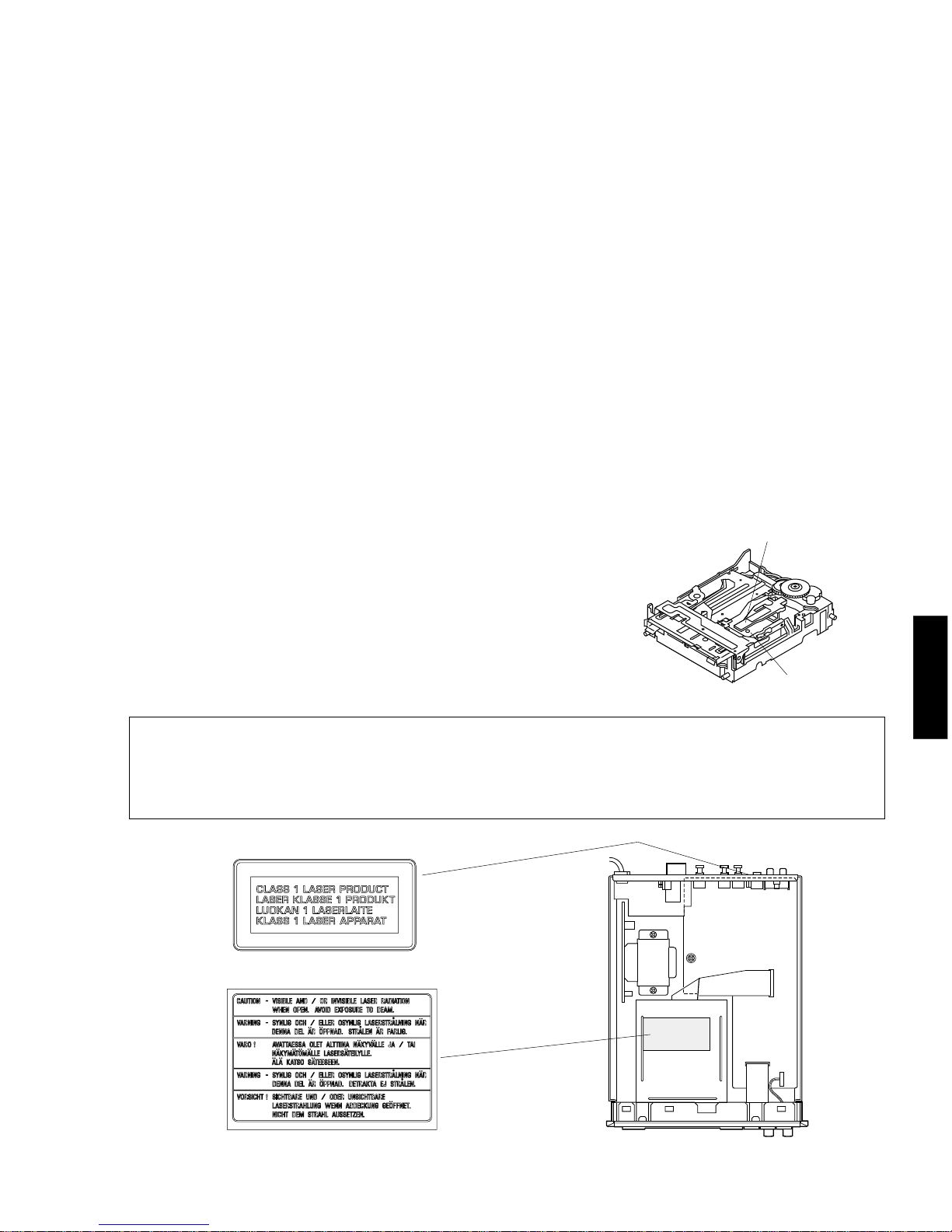

THE MINI DISC RECORDER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE EXCEPT PROPERLY QUALIFIED

SERVICE PERSONNEL.

TROUBLESHOOTING /トラブルシューティング .....

36–45

IC DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46–55

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . 56–57

TEST POINT WAVEFORMS . . . . . . . . . . . . . . . . . . . 58

PRINTED CIRCUIT BOARD . . . . . . . . . . . . . . . .59–62

MD VOLTAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . .63–64

DISPLAY DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66–77

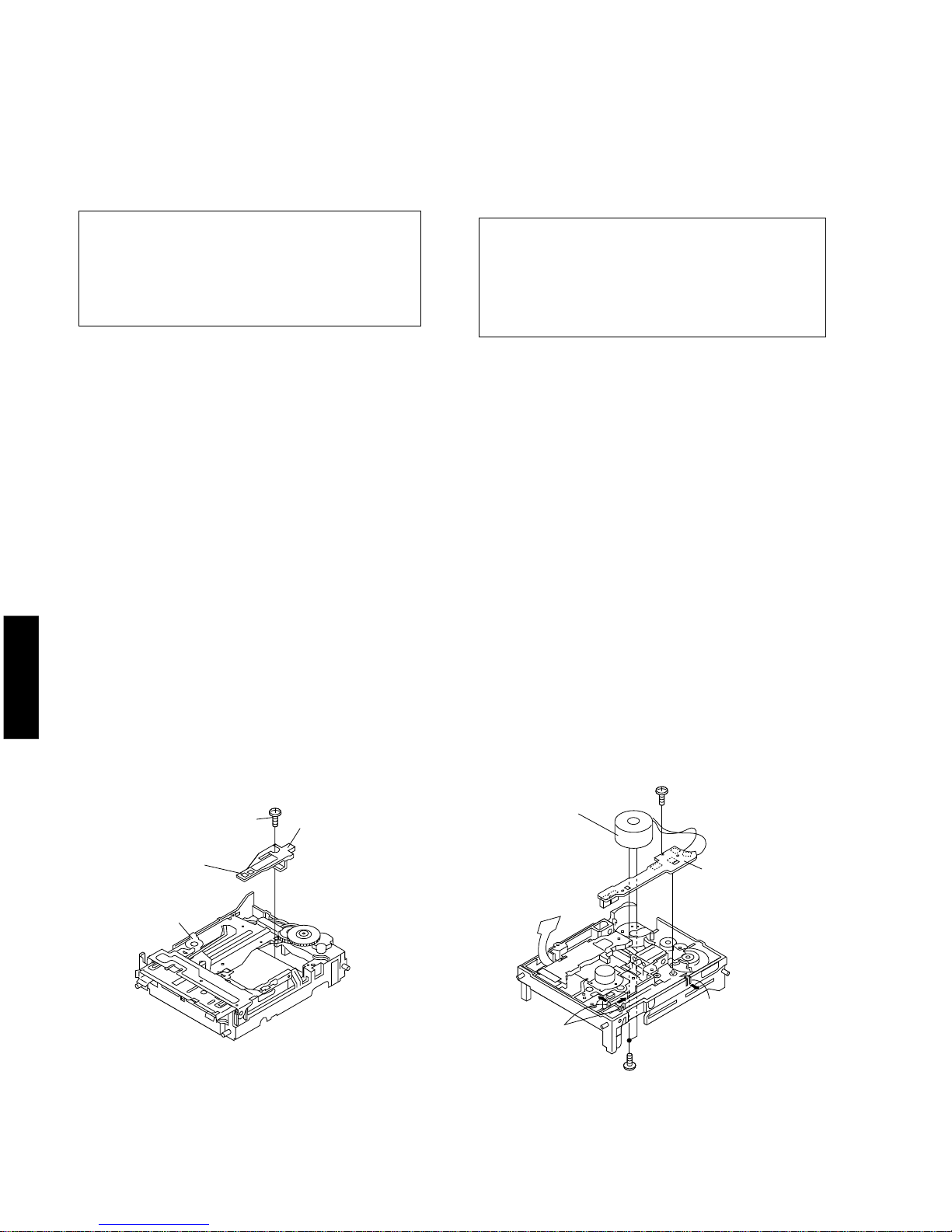

GREASE APPLICATION DIAGRAM . . . . . . . . . . . . 78

REMOTE CONTROL TRANSMITTER . . . . . . . . . . . 79

PARTS LIST FOR CARBON RESISTORS . . . . . . . 80

■ CONTENTS

TO SERVICE PERSONNEL . . . . . . . . . . . . . . . . . . 2–3

PREVENTION OF ELECTRO STATIC DISCHARGE . . . . . .

4

REAR PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

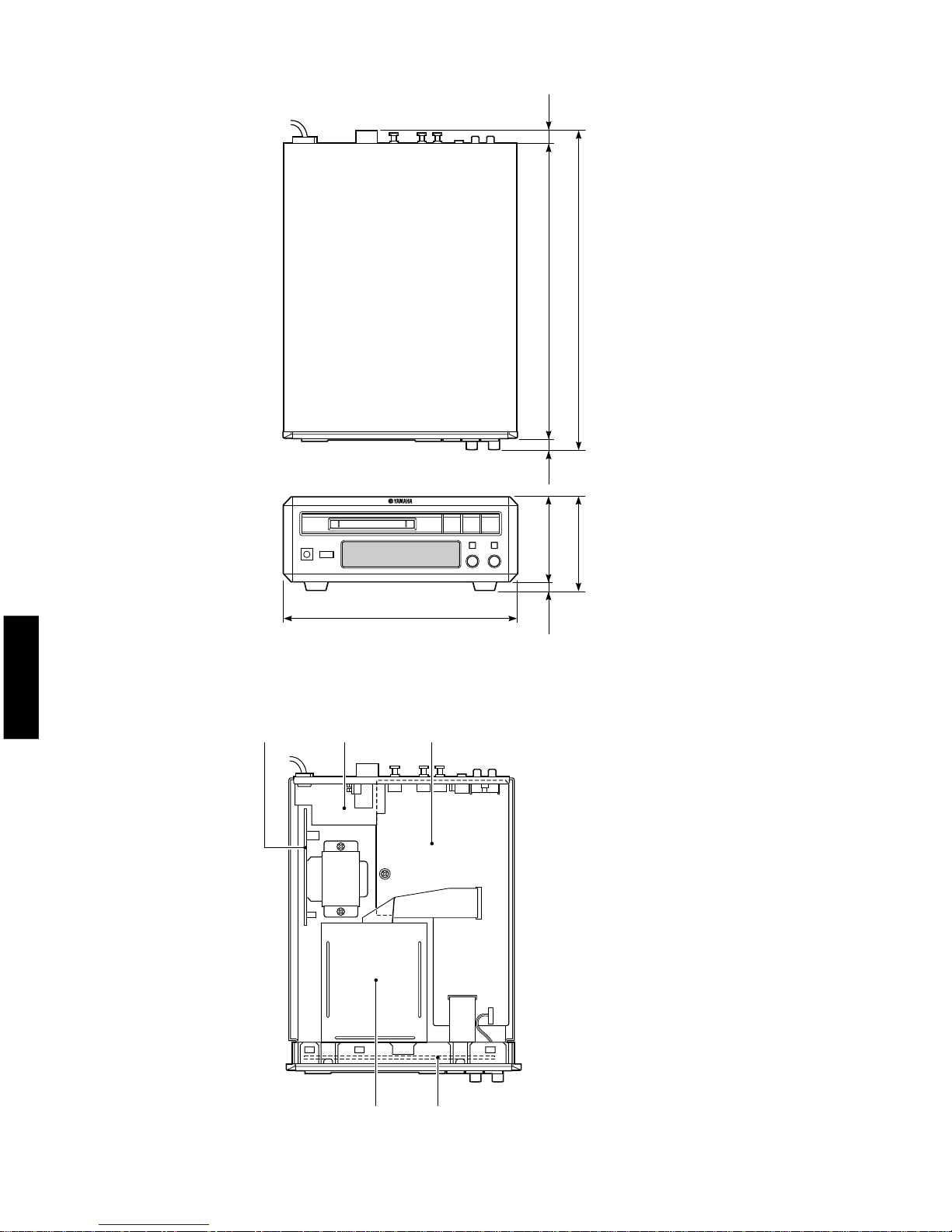

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

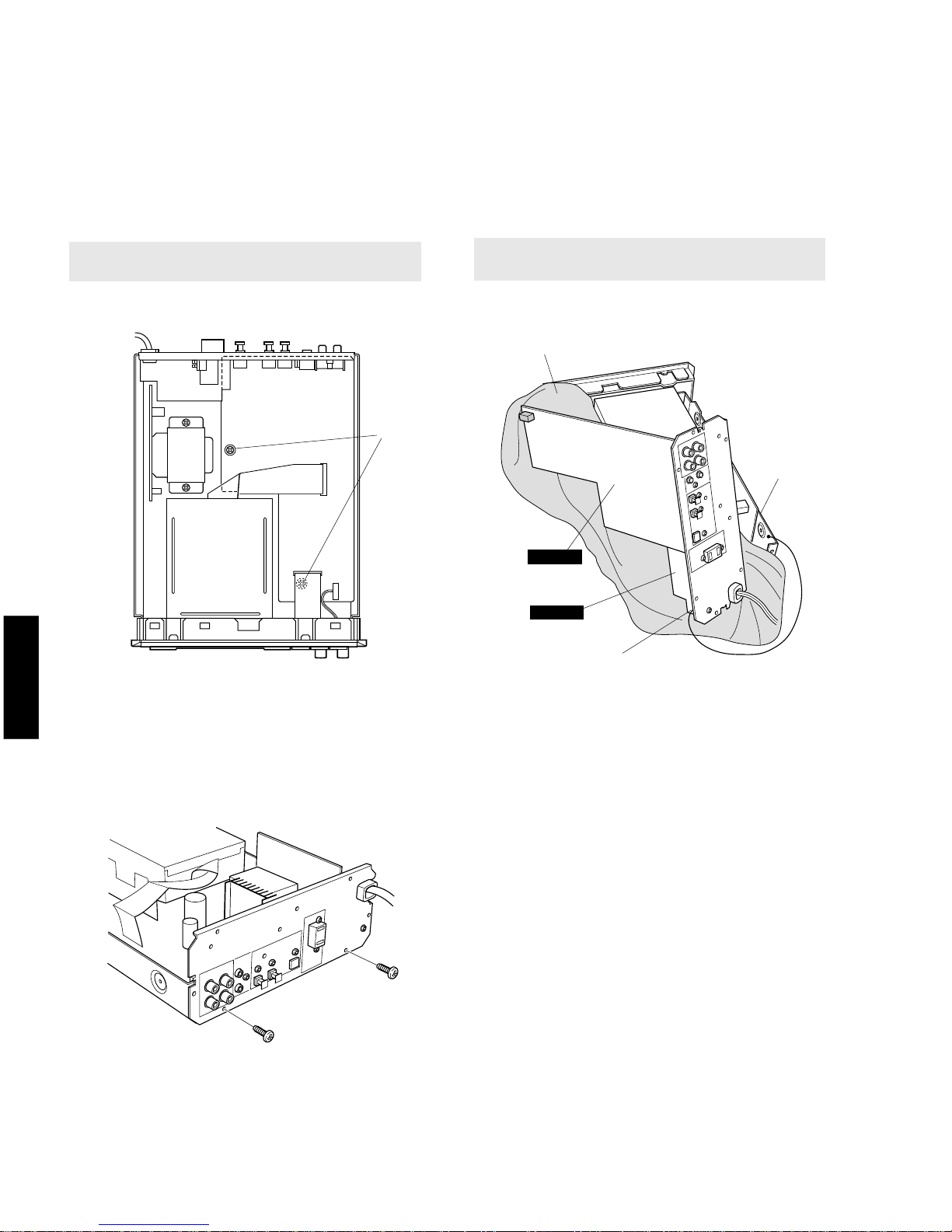

INTERNAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DISASSEMBLY PROCEDURES /分解手順 ...... 7–8

DISASSEMBLY OF MD RECORDER UNIT /

MDレコーダーユニットの分解 ................... 9–11

ADJUSTMENT & TEST MODE /

調整及びテストモード ........................ 12–29

SPECIAL TEST MODE /特殊テストモード ..... 30–31

ERROR DISPLAY /エラー表示 .............. 32–35