Yamaha PX-2 User manual

Other Yamaha Turntable manuals

Yamaha

Yamaha P-520 User manual

Yamaha

Yamaha P-520 User manual

Yamaha

Yamaha PX-2 User manual

Yamaha

Yamaha YP-D71 User manual

Yamaha

Yamaha YP-700 User manual

Yamaha

Yamaha YP-D6 User manual

Yamaha

Yamaha TT-S303 User manual

Yamaha

Yamaha PX-2 User manual

Yamaha

Yamaha TT-400URS User manual

Yamaha

Yamaha P-850 User manual

Yamaha

Yamaha YP-700 User manual

Yamaha

Yamaha TT-400 User manual

Yamaha

Yamaha PX-2 User manual

Yamaha

Yamaha YP211 User manual

Yamaha

Yamaha PF-800 User manual

Yamaha

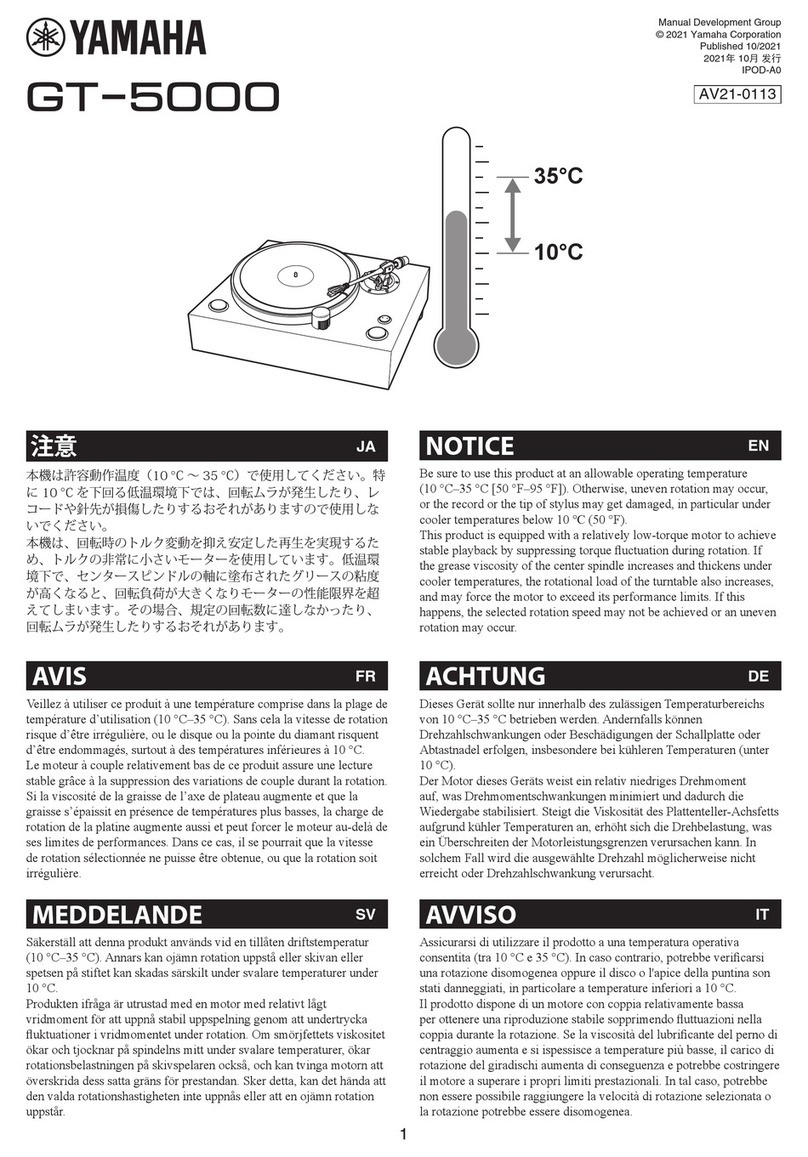

Yamaha GT-5000 User manual

Yamaha

Yamaha GT-5000 User manual

Yamaha

Yamaha MusicCast VINYL 500 User manual

Yamaha

Yamaha P-450 User manual

Yamaha

Yamaha TT-S303 User manual