7

IV.OPERATION

Fuel Cock

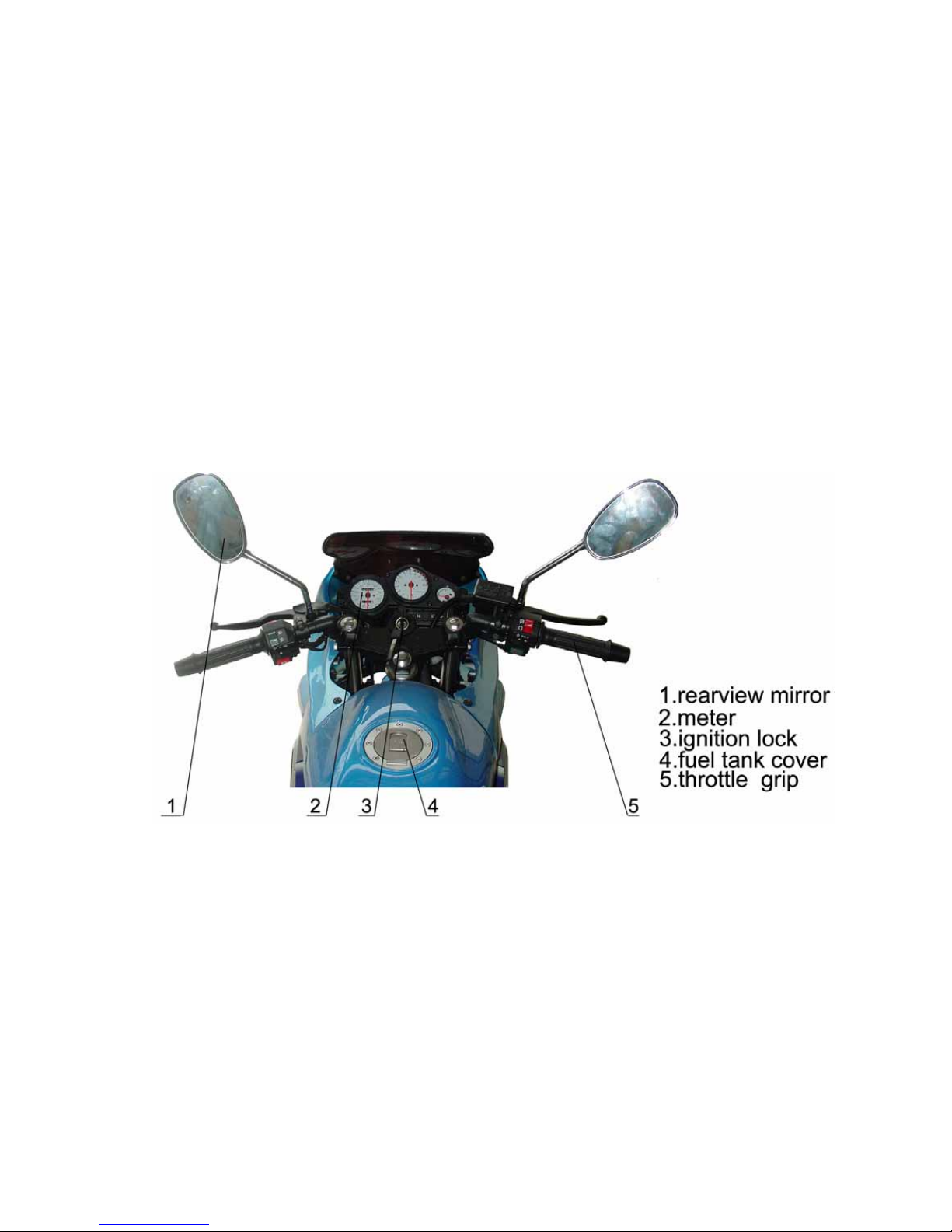

1.Fuel filling

The capacity of the fuel tank is 4.5L.Leadless gasoline

of No.90or above or low-lead gasoline is required for the

motorcycle.To fuel the vehicle,support it by the main stand,

open the lock cover of the fuel tank and fill fuel through the

opening.

Operation of the fuel cock

ON:With the handle of the fuel cock to

“ON”position,the fuel circuit is through for fuel supply.

OFF:With the handle of the fuel cock fo “OFF”

position,the fuel circuit is cut off without supply.

RES: With the handle of the fuel cock to “RES” position, the

fuel is supplide from the reserve.(Note:The reserved fuel can

only be used when the normal supply is run

out,) In this case,refueling should be carried

out as soon as possible; for there is only

somel.0L of fuel reserve for use.