WARNING

3.6 Maintenance, inspection and repair

○ Maintenance, inspection, and repair must be

performed by staff that have received special

training and fully understand and follow the

information in the instruction manual.

○ Be sure to turn off the power supply switch

and make sure the sewing machine and motor

completely stop before the maintenance,

inspection, and repair. (If the machine is

using a clutch motor, take care that the

motor keeps turning for a while even after

turning off the power supply switch.)

4. Recommended check points for maintaining

machine performance

(1) Perform regular cleaning of the machine parts

by following the instruction manual.

(2) Perform regular inspection of the lubrication

oil by following the instruction manual, and

rell or replace the oil as required.

(3) Because the oil-proof parts use rubber, their

oil-proof performance is reduced over time.

○ If the seals or other stationary parts

fall off or begin to lose their sealing

performance, replace them with new parts.

○ The replacement period for parts used in

the movable sections varies depending

on the machine operating conditions,

environment, maintenance, and oil used,

but replacement every several years is

recommended.

(4) For details about the replacement procedure,

please contact your local dealer or Yamato.

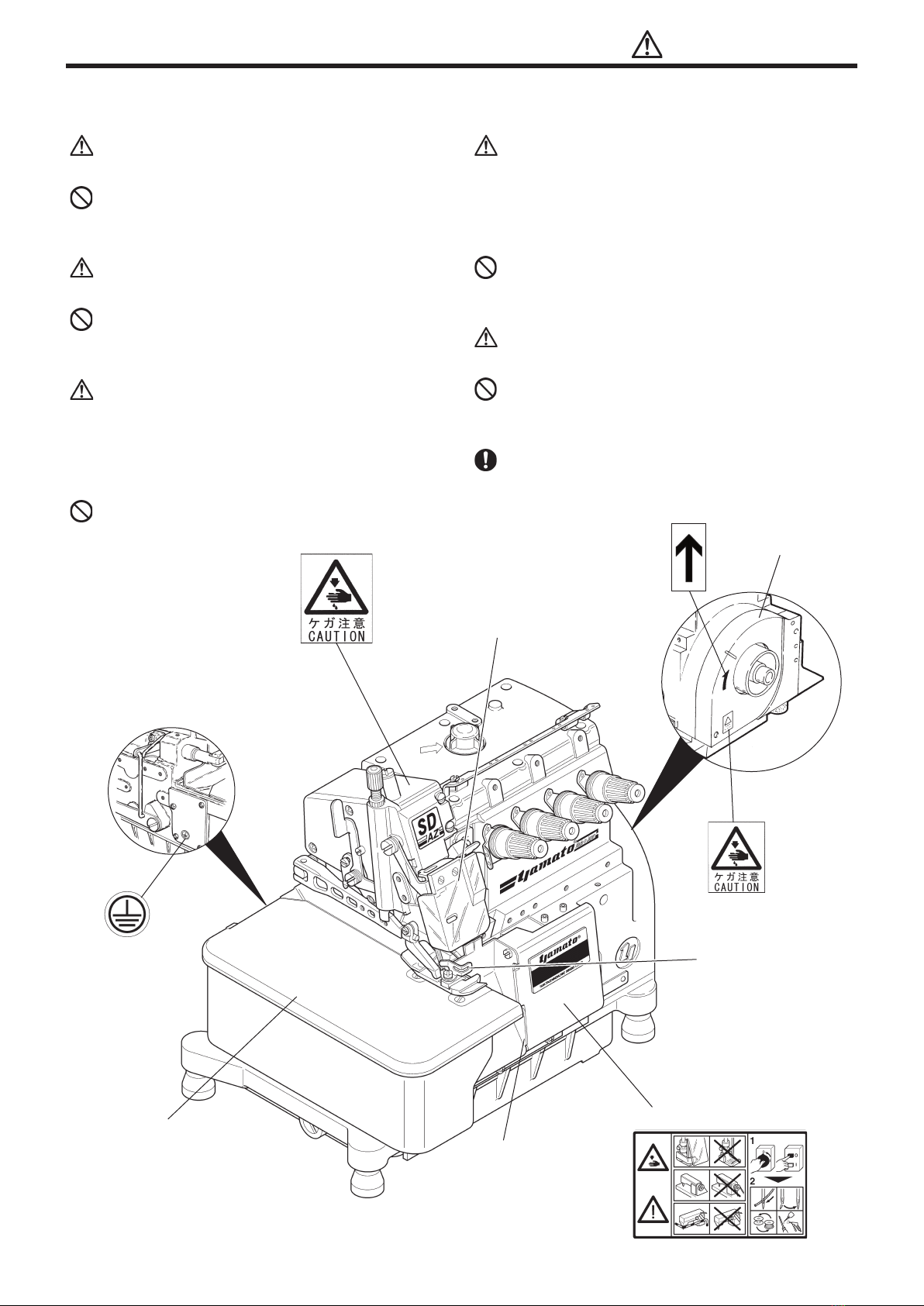

WARNING

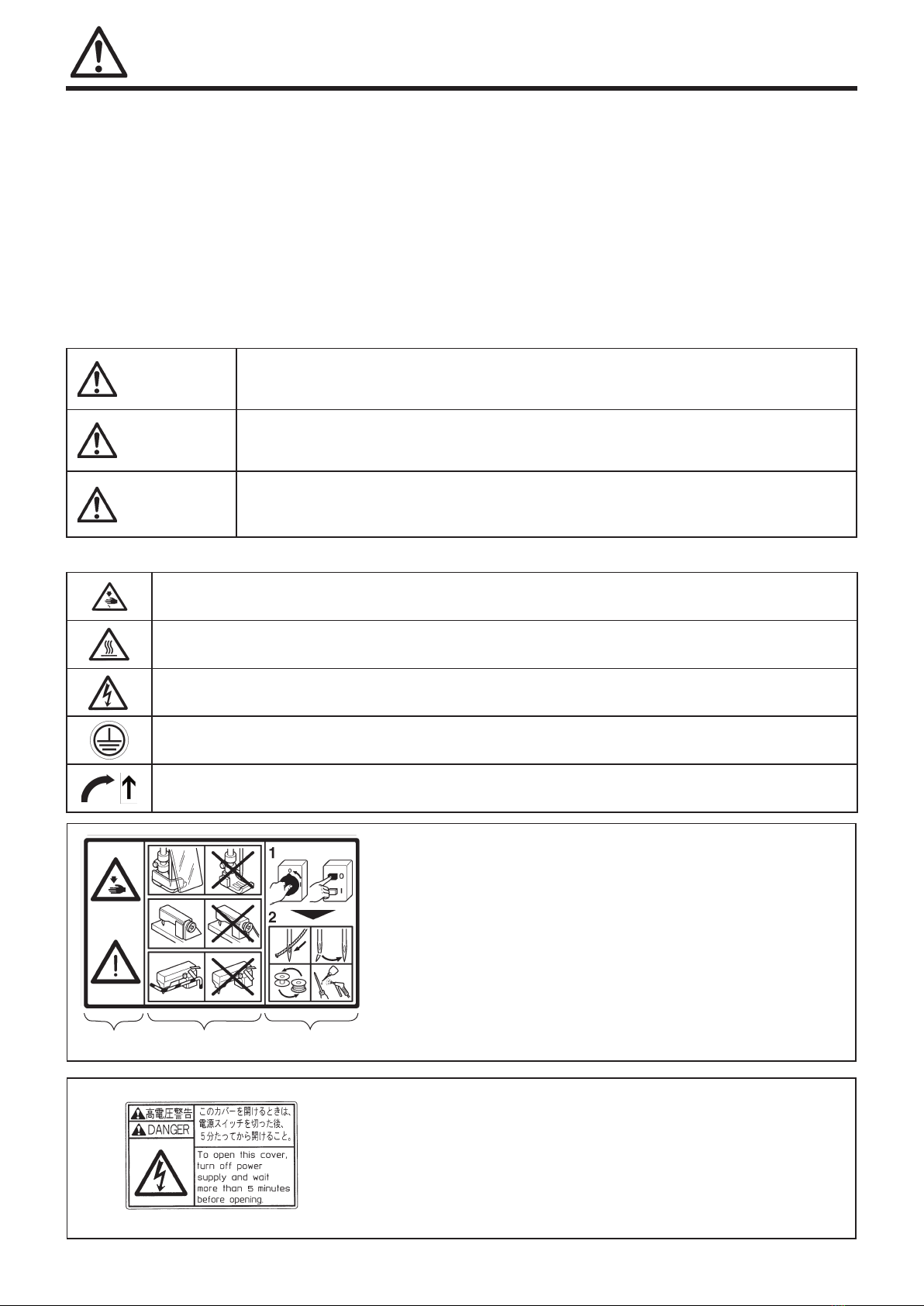

3.5 During operation

○ Be sure to operate the sewing machine using

the safeguards such as belt cover, nger

guard, and eye guard.

○ Never place your nger, hair or objects under

the needle or close to the moving parts while

operating the sewing machine.

○ Be sure to turn off the power supply switch

when threading or replacing the needles.

○ Never place your hands close to the knives

(upper and lower knives) when operating the

sewing machine with the trimming devices.

○ Be sure to turn off the power supply switch

when terminating the sewing work or leaving

the sewing machine.

○ In the event of the power failure, be sure to

turn off the power.

Also, if the sewing machine malfunctions,

makes abnormal sound or emits unusual odors

while operating, be sure to turn off the

power supply switch.

○ While operating the machine, wear clothing

that cannot be caught in the machine.

○ Do not put any tools or other unnecessary

objects on the machine table while running

the machine.

○ If a clutch motor type is used, it will

continue running for a while even after the

power is turned off. Therefore, be careful

because the machine could start running by

pressing the machine pedal.

○ If a servomotor is used, the motor does not

produce noise while the machine is at rest.

Be sure not to forget to turn the power off

in order to prevent accidents caused by

abrupt starting of the machine or motor.

○ To prevent entanglement accidents in machines

with a puller mechanism, keep your hands,

hair, and clothing away from the machine.

○ Do not attempt to modify the machine at your

own discretion. We are not responsible for

accidents caused by such modication.

○ Use genuine Yamato parts when repairing the

machine and/or replacing the parts. We are

not responsible for accidents caused by any

improper repair/adjustment and substituting

other parts for those manufactured by Yamato.

○ Turn off the power supply switch if removing

or replacing any parts or during adjustment

of the sewing machine.

○ Be sure to also remove the gasket if the

cover is removed for maintenance, inspection,

and repair. If the gasket is not removed, the

edge of gasket may cause injury.

○ Do not pull the cord when removing the plug.

Be sure to hold the plug itself.

○ A high voltage is applied inside the control

box. Turn off the power supply switch and

wait for at least ve minutes before opening

the cover.

○ Be sure to replace the safety devices and/

or safety covers if removed for maintenance,

inspection and repair.

○ After performing maintenance, inspection and

repair, make sure that turning on the power

does not pose any danger to you.

When operating the machine for the rst time

after work is performed, run at low speed to

check for abnormal sounds or other problems

before performing high-speed operation.