-8-

5-6 Adjusting Differential Feed

Normal differential feed or reverse differential feed can

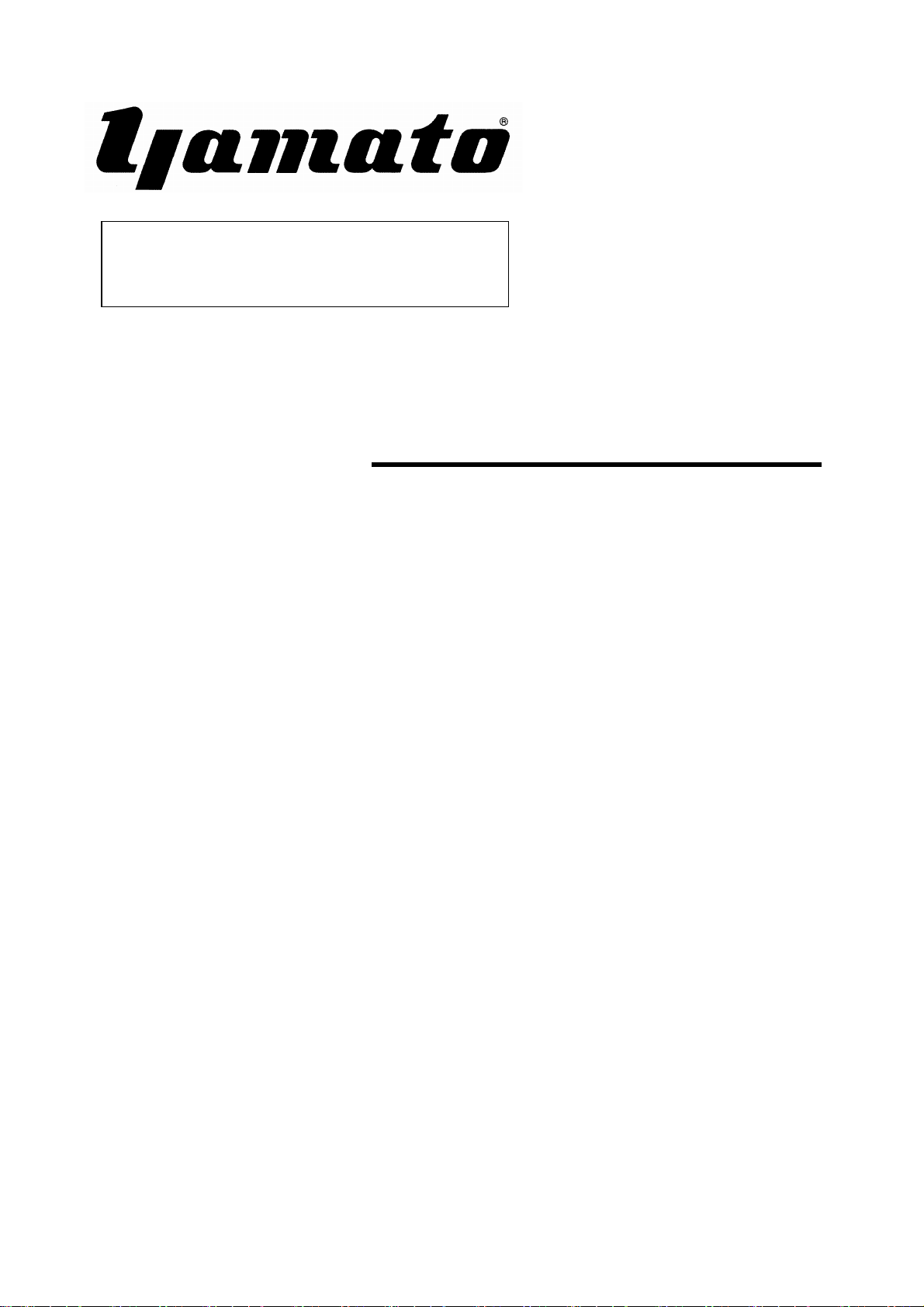

be set freely by turning Knob①.

As differential feed and main feed is driven individually,

when main feed amount (stitch length) is changed, the

differential ratio changes accordingly.

In this case readjustment is necessary.

The graduation shows the amount of differential feed.

For instance, in case the desired feed amount (stitch

length) is "2" and if the graduation is set at "2" by turning

Knob①, the differential ratio becomes 1:1.

When setting the graduation over "2", it becomes norma l

differential and setting it under "2", it becomes reverse

differential.

For the main feed amount the upper limit is "4".

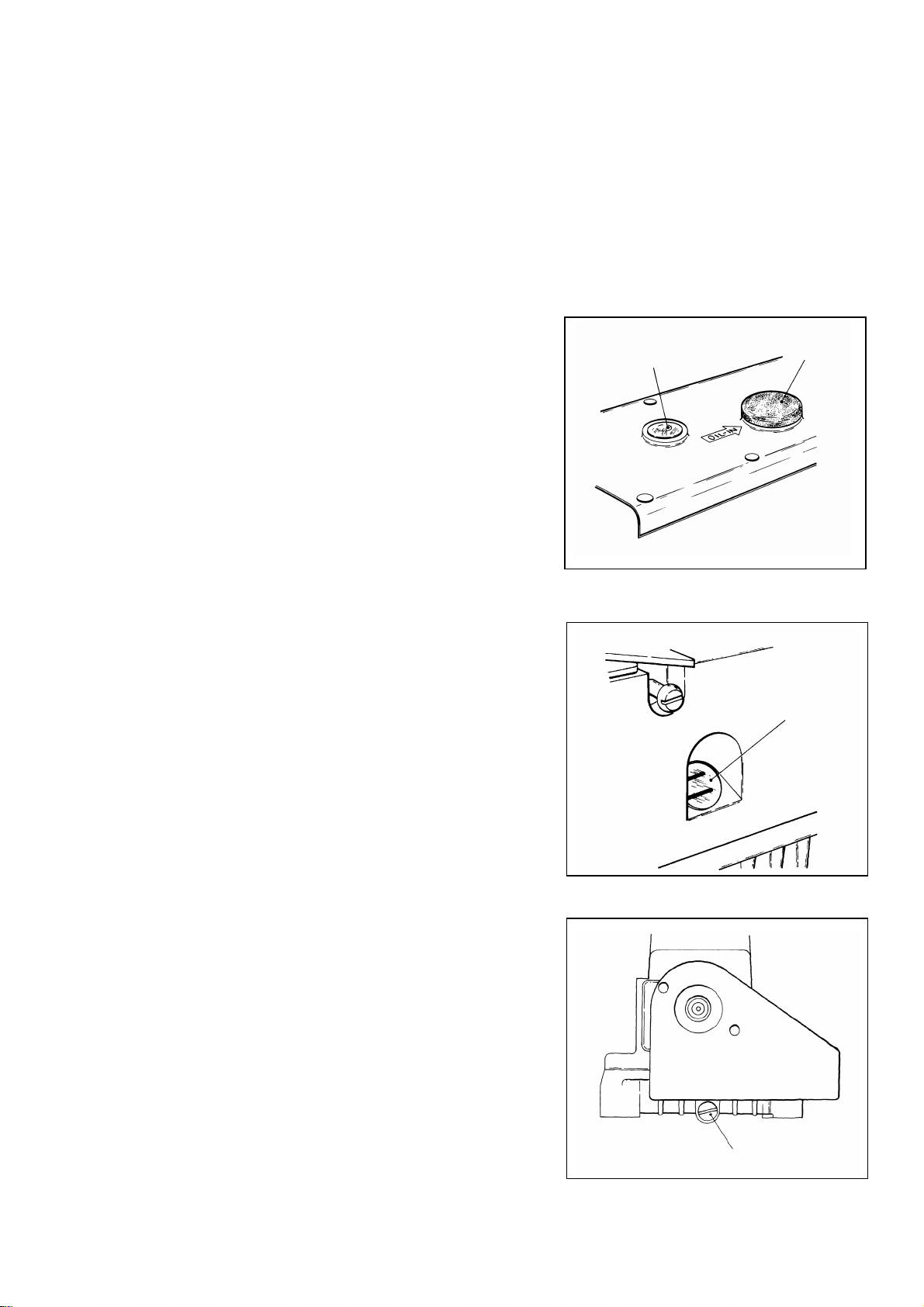

✽When using Differential Feed Control Lever Fix

Differential Feed Control Lever at the desired position

with Nut ③ within the range from the position of

graduation on Lever when turning Knob① to Stopper

②.

At the time of using max. differential feed, turn Knob

① and set Lever at graduation "1".

For adjusting feed amount during operation, attach a

chain to the Lever.

※The range of differential ratio varies according to the

stitch length. Refer to the table below:

stitch length max. normal

differential

max.

reverse

differential

3.6㎜ 1:1.1 1:0.3

2.5㎜ 1:1.6 1:0.4

2.0㎜ 1:2 1:0.5

1.4㎜ 1:2.9 1:0.7

①

②③