i

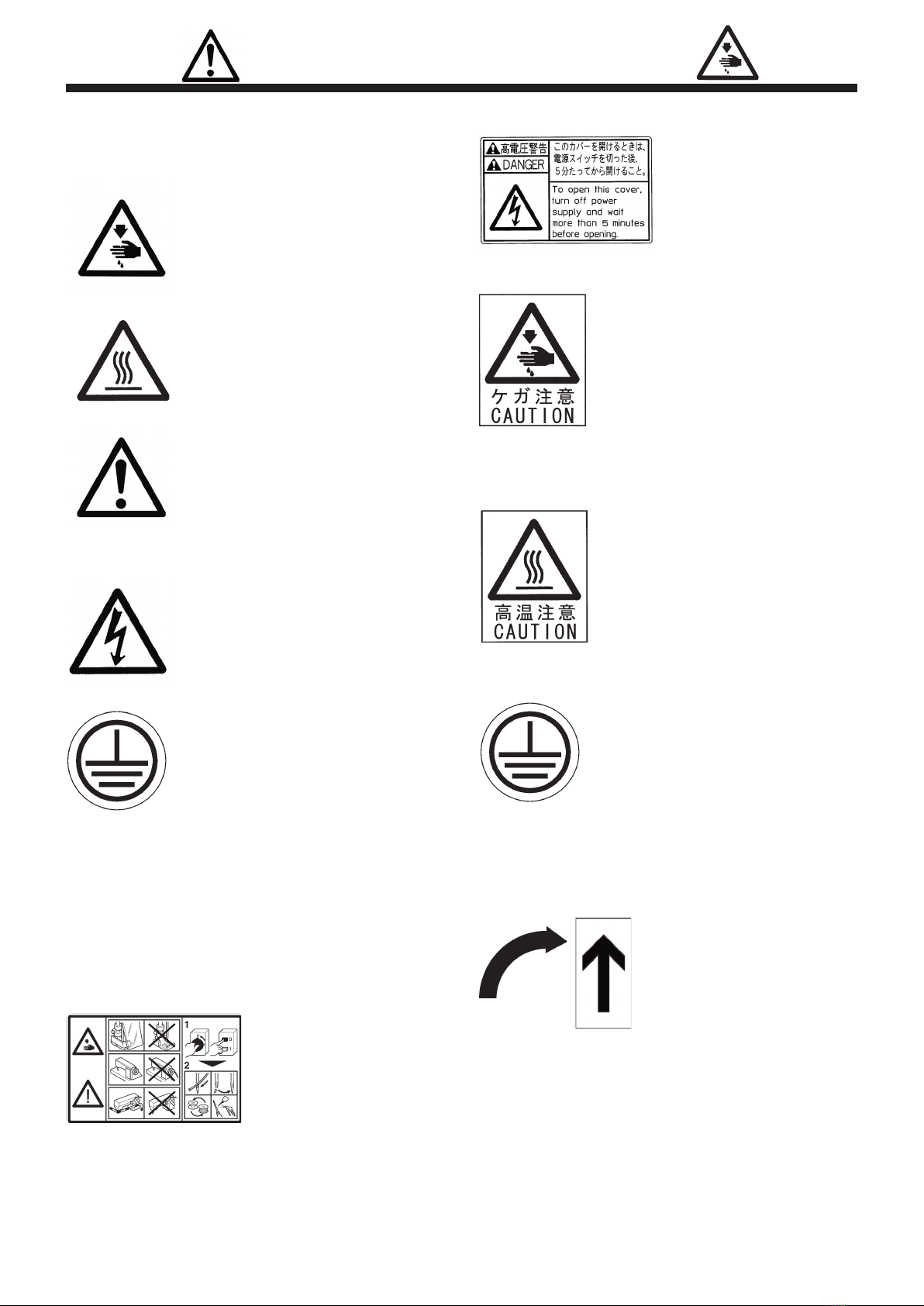

Safety instructions

2.Installation and preparation

2-1 Instruction and training

Operators and workers, who supervise, repair or

maintain the machine head and machine unit, are

required to have the adequate knowledge and op-

eration skills to do the job safely. In order to

establish such necessary conditions, it needs

for the employer to plan and enforce the safety

education and training to those workers.

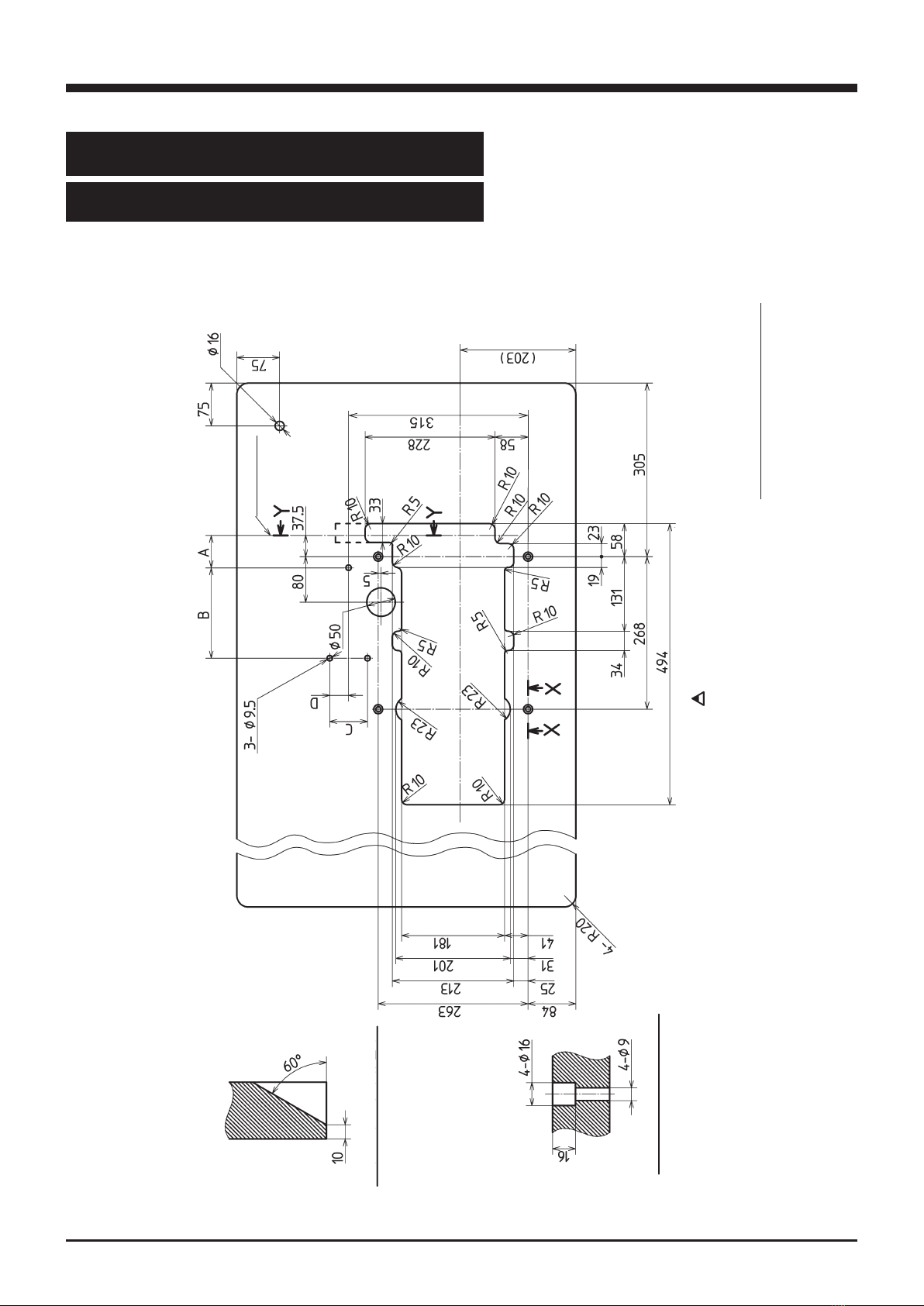

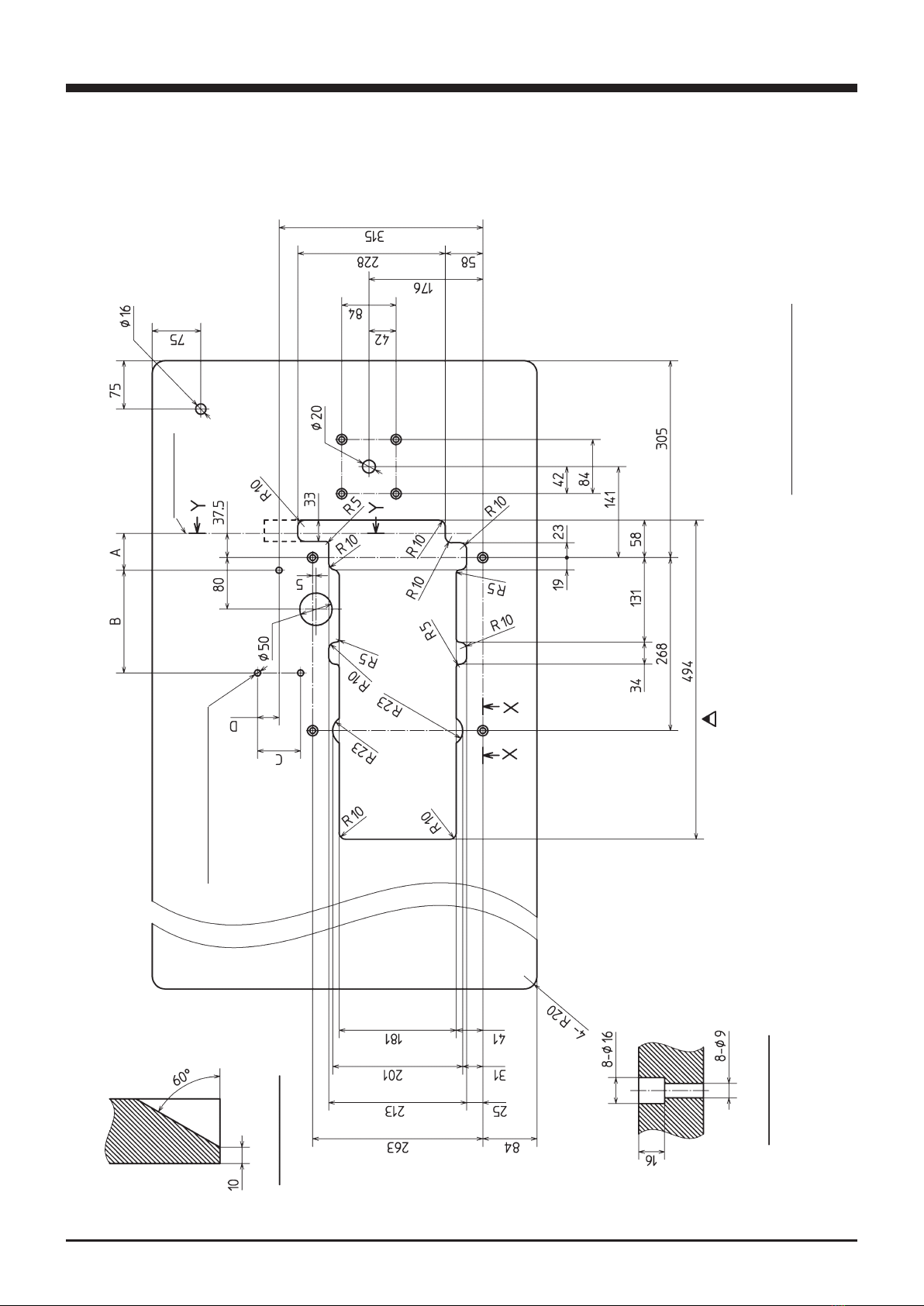

2-2 Sewing table and motor

(1) Prepare a machine table that has enough

strength to withstand the weight of the sew-

ing head and any reaction while operating.

(2) Maintain a comfortable working environment

with considering the lighting and the ar-

rangement of sewing machine so that the op-

erators can work smoothly.

(3) When installing the control box and the re-

lated parts on the sewing machine, take care

about the posture of the worker.

(4) Install the drive unit correctly according

to the instruction manual.

2-3 Wiring

(1) Never connect the plug for power supply un-

til assembly is nished.

(2) Fix the connectors securely to the sewing

machine head, motor, and electric apparatus.

(3) Do not apply excessive force to the connec-

tion cords.

(4) Connect the cords away from the driving

parts.

(5) Place the ground wire securely to the desig-

nated position on the machine head.

2-4 Before operation

(1) Take care not to attach lubricant, silicone

oil, and grease on the eyes or skin.

Keep them away from children.

(2) Be sure to ll or drop lubrication oil be-

fore operating the sewing machine.

Use the Yamato SF oil as specied.

(3) Never put your hand under the needle or near

the moving parts of the machine when turning

on power supply switch.

1. To ensure safe use

Always observe the following instructions to en-

sure the safe use of the industrial sewing ma-

chines and devices.

1-1 Application and purpose

The sewing machine is designed to improve pro-

ductivity in the sewing industry and must not be

used for other applications and purposes. Do not

use this sewing machine until it can be conrmed

that safety measures for the drive units have

been taken.

1-2 Before use

Read all instruction manuals thoroughly before

starting the use of this machine and follow

them.

Also, read the instruction manual for the installed

drive unit.

1-3 Working environment

DO NOT WORK IN THE FOLLOWING ENVIRONMENTS:

- Place where atmosphere temperature and humid-

ity give a bad influence the performance of

sewing machines.

- Outdoors and place where the sewing machines

are exposed to sunlight directly.

- Atmosphere containing dust, corrosive gases or

ammable gases.

- Place where voltage uctuation exceeds ± 10 %

of the rated voltage.

- Place where power capacity necessary for the

used motor specications cannot be secured.

- Place where strong electric or magnetic elds

are generated such as near large-output high

frequency transmitters or high frequency weld-

ing machines.

1-4 Unpacking and transportation

(1) Unpack from the top.

(2) Never hold the parts near the needle or

threading parts when removing the sewing ma-

chine head from the buffer of box.

(3) When carrying the sewing machine head, have

an assistant.

(4) Pay attention not to get excessive impact or

shock when moving the sewing machine head

with a pushcart.