Contents

Cautions in Using with Safety ...................................................................1

Explanation..................................................................................................................1

Table of Illustrated Symbols .........................................................................................2

Fundamental Matters of “WARNING!” and “CAUTION!” ...............................................3

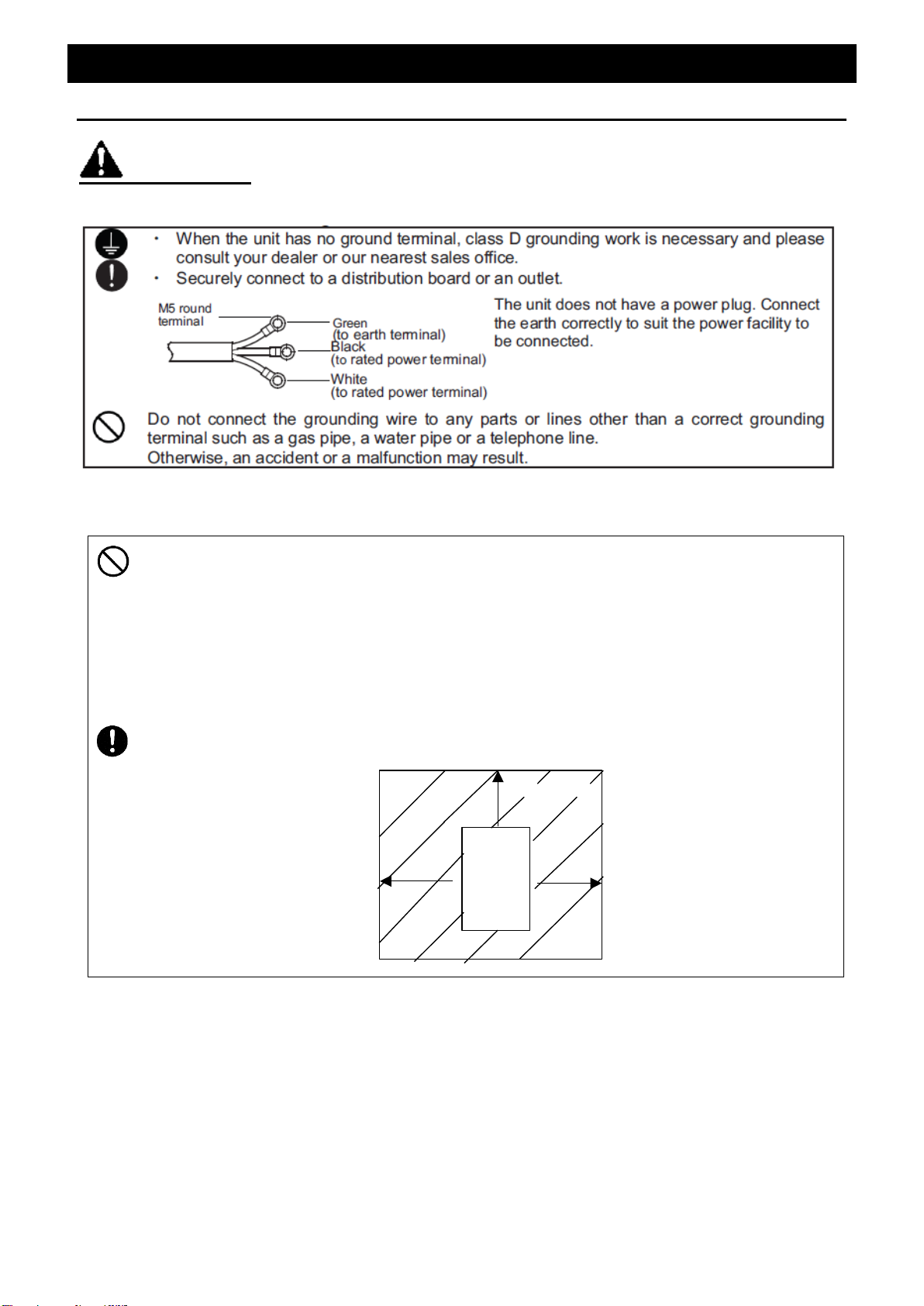

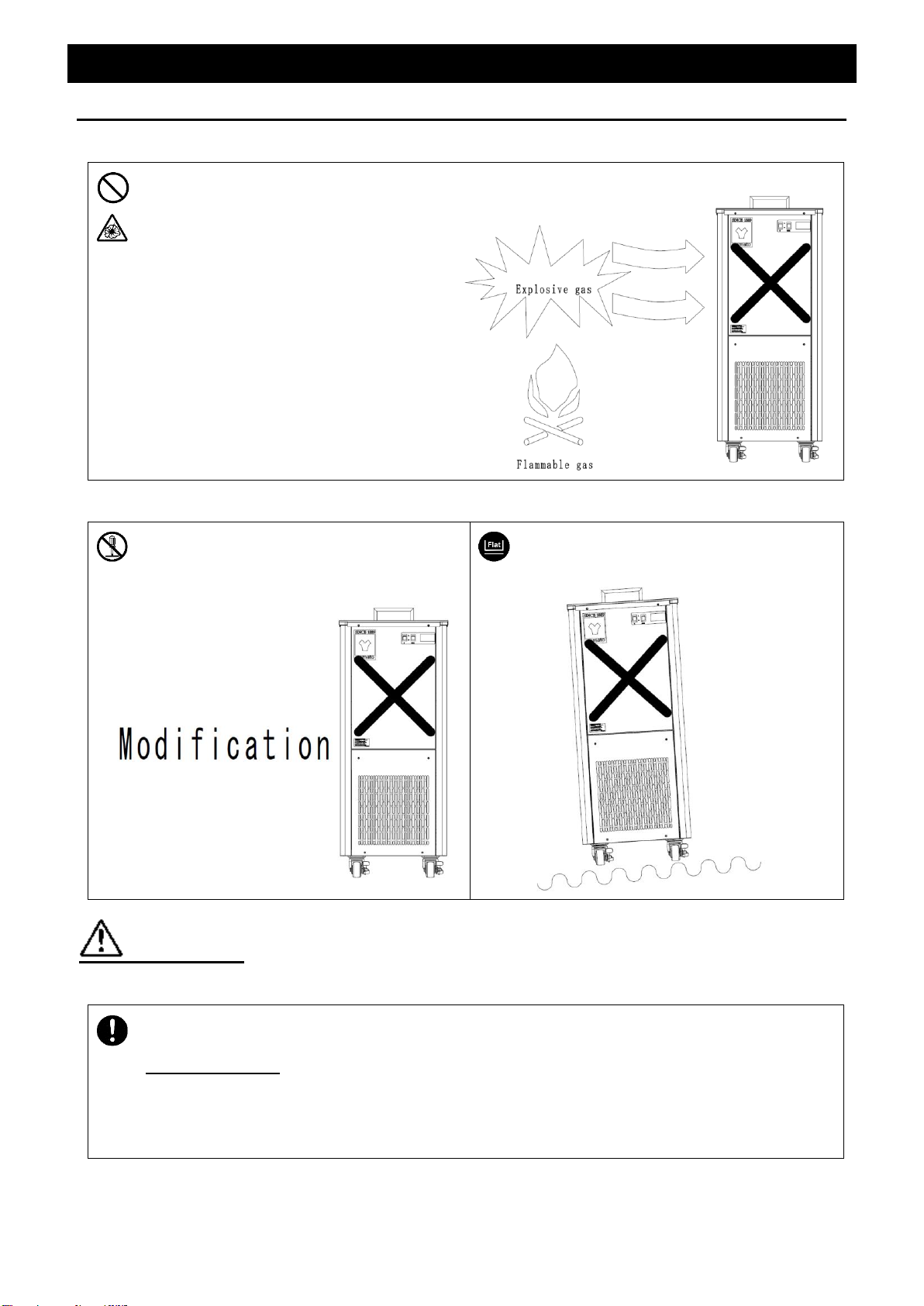

Before Using this unit ................................................................................5

Requirements for Installation........................................................................................5

Description and Function of Each Part...................................................10

Main Unit and Control panel.......................................................................................10

Installation Method...................................................................................12

Operation Method.....................................................................................14

Procedure of Operation..............................................................................................14

Heating and cooling curve, cooling capacity curve (reference data)...........................15

Flow Rate and Head (reference data)........................................................................16

Selecting heat medium for lower temperature (reference data)..................................17

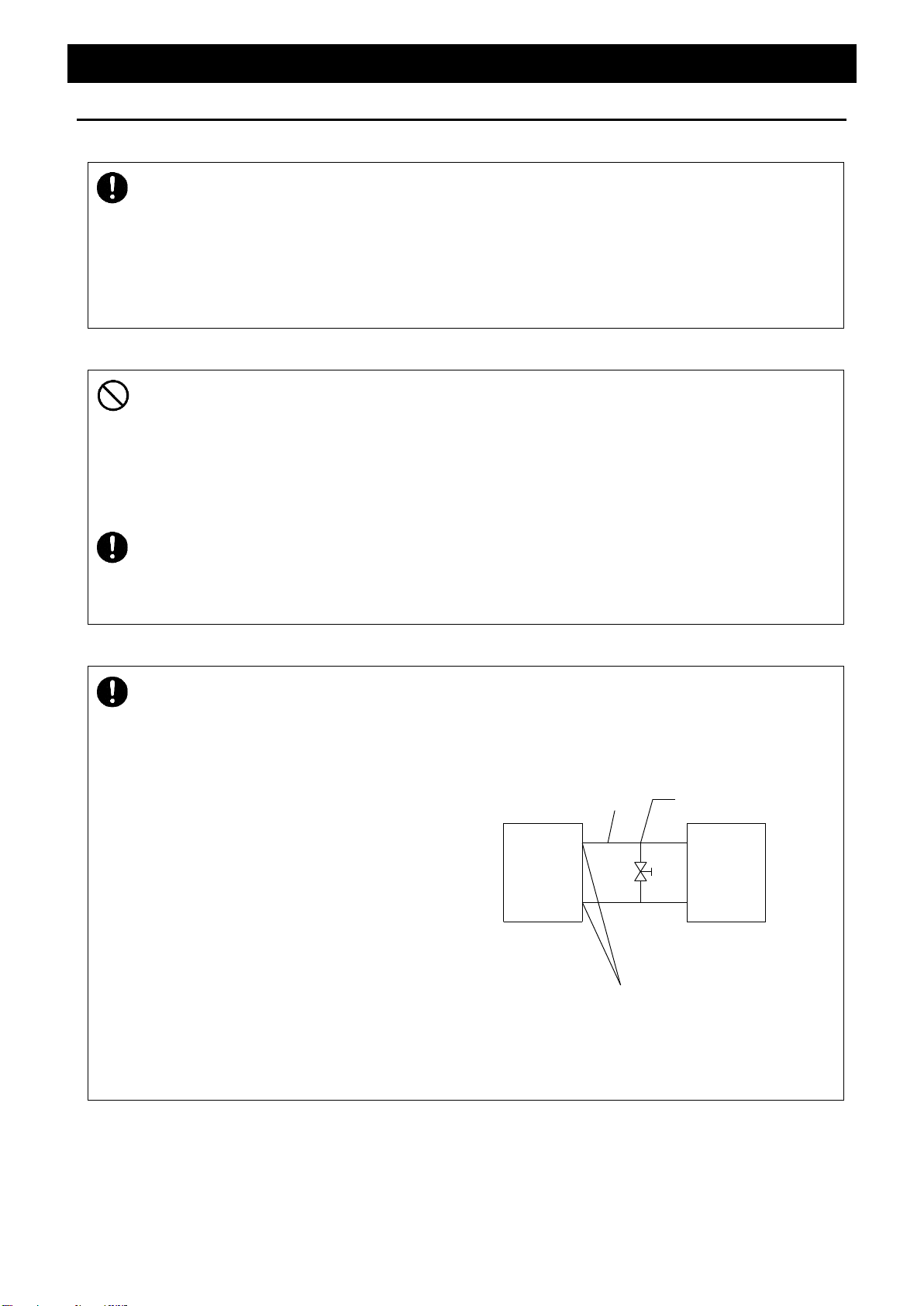

Handling Precautions...............................................................................18

Maintenance Method................................................................................21

Daily Inspection and Maintenance..............................................................................21

Long storage and disposal......................................................................23

When not using this unit for long term / When disposing............................................23

Notes about disposition..............................................................................................23

In the Event of Failure…...........................................................................24

After Service and Warranty......................................................................25

Specification.............................................................................................26

Wiring Diagram.........................................................................................27

Replacement Parts Table .........................................................................28

Reference..................................................................................................29

List of Dangerous Substances ...................................................................................29

Standard installation manual...................................................................30