Yard force GT A42 User manual

Hotline : 1300 418 640

Monday - Friday : 9.00am to 4.30pm

Saturday: 9.00am to 3.00pm

Email: [email protected]

Model: GT A42

OPERATOR’S MANUAL

PETROL BRUSH CUTTER

WARNING!

Read this manual carefully before using your brush cutter and keep it

in a safe place for future reference.

2

GT A42 OPERATING MANUAL

TABLE OF CONTENTS

WELCOME

Thank you for choosing to buy a YARDFORCE brush cutter.

All our products are manufactured to the highest standards of performance

and safety.

Please read this operator’s manual carefully.

WELCOME ......................................................................2

TABLE OF CONTENTS .................................................2

INTENDED USE .............................................................3

TECHNICAL SPECIFICATIONS ...................................3

PARTS IDENTIFICATION ..............................................4

SCOPE OF DELIVERY ..................................................5

SAFETY INFORMATION ...............................................6

PREPARATION ...............................................................10

OPERATION ...................................................................15

MAINTENANCE ..............................................................19

TROUBLESHOOTING ...................................................20

STORAGE .......................................................................21

WARRANTY ....................................................................22

3

INTENDED USE

TECHNICAL SPECIFICATIONS

This tool is designed for the following applications:

- Brush cutter (when tted with metal circular blade)

The brush cutter is intended to cut weed and climbing plants. Do not use it

for other purposes that it was not intended. Example, never use it for cutting

wood. Never cut objects with a diameter exceeding 13mm.

- Grass trimmer (when tted with nylon line cutting head)

The grass trimmer is intended for trimming grass. Do not use it for other

purposes.

Note: This tool is designed for domestic use. It is not designed for or

warranted for use in commercial, trade or industrial applications.

Model GT A42

Engine Type 2-Stroke Euro V

Displacement 33 cc

Max. Cutting speed 7000 rpm

Rated Power 0.9 kw

Metal Blade size 1.4 x 255 x 25.4 mm

Max. Cutting Capacity Ø 13 mm

Nylon Line Cutting Head (Max. Cut) 420 mm

Nylon LIne size 2 mm

Fuel Capacity 0.7 L

Fuel/Oil Ratio 40:1

Easy Start Yes

Net Weight 8 kg

USE FRESH UNLEADED FUEL (PETROL), 90

OCTANE OR BETTER – Do NOT use E10 or

Ethanol blends.

Mix with a premium grade air cooled 2 stroke oil

at a ratio of 40:1

40:1

4

PARTS IDENTIFICATION

1

9

10

11

12

13

14

16

2

4

5

6

7

8

3

1. Spark plug.

2. Starter.

3. Fuel cap.

4. Air lter.

5. Strap attachment point.

6. Left handle.

7. Shaft joint clamp.

8. Guard.

9. Cutting Head.

10. Cutting blade.

11. Right handle.

12. Throttle lever.

13. Throttle lock button.

14. ON /OFF switch.

15. Throttle interlock.

16. Control cable.

15

5

SCOPE OF DELIVERY

A. Engine, upper shaft and

right handle assembly.

B. Lower shaft.

C. Left handle.

D. Guard.

E. Line trimmer spool.

F. Metal cutting blade.

G. Shoulder belt.

H. Bracket for guard.

I. Hex keys,1 x 4mm,

1 x 5mm.

J. Spark plug spanner.

●Remove all packing material.

●Check the completeness of the package content.

●Check the tool and its accessories for transportation damage.

WARNING! Danger of suocating! Packing materials are not toys!

Children must not play with plastic bags!

IF ANY PARTS ARE MISSING OR DAMAGED,

PLEASE CONTACT ACTION SPARES 1300 418 640

Recycle/dispose of packaging materials in accordance to the regulations

and requirements of your local council.

A

B

C

D

J

GH

I

E

F

6

SAFETY INFORMATION

GENERAL

WHEN using the product, a few safety precautions must be observed to avoid

injuries and damage to the product.

READ the operating instructions carefully and comply with them at all times.

KEEP this manual in a safe place so that the information is readily available at

all times.

IF you give the equipment to another person it is important for them to read

the operating instructions prior to use.

DESCRIPTION OF SYMBOLS

Symbols are used in this manual and/or on the product to attract your attention

to possible risks. These symbols and the explanations that accompany them

must be understood.

WARNING! To reduce the risk of injury all users must read the

operator’s manual before using the product.

Risk of ying debris.

Keep bystanders away at least 15 metres.

WARNING! or CAUTION! This symbol before a safety comment

indicates a precaution, warning or danger.

Ignoring these warnings can lead to an accident for yourself or for

others. To limit the risk of injury, re or electrocution always follow the

recommendations indicated.

Wearing eye, ear and head protection.

Do NOT use saw blades.

Wear gloves while using.

Wear sturdy footwear.

7

Australian regulatory compliance mark.

SAFETY INSTRUCTIONS

TRAINING

A. Read the instructions carefully. Get familiar with the controls and

proper use of the tool.

B. Only use the tool for the purpose for which it was designed. Any

other use can be hazardous and may also cause damage to the tool.

C. Never allow children or people unfamiliar with these instructions to

use the tool. Local regulations may restrict the age of the operator.

D. Never use the tool:

• When people, especially children, or pets are nearby.

• If the operator has taken medicine or substances that can

aect his ability to react and concentrate.

E. Remember that the operator or user is responsible for accidents or

hazards occurring to other people or their property.

WARNING! Proper safety precautions must be observed. Like

all power equipment this tool must be handled carefully. DO NOT

EXPOSE YOURSELF OR OTHERS TO DANGER. Follow these

general rules. Do not permit others to use this tool unless they are

trained in its operation.

WARNING! THIS TOOL CAN CAUSE SERIOUS INJURIES. Read

the instructions carefully for the correct handling, preparation,

maintenance, starting and stopping of the tool. Be familiar with all

controls and the proper use of the tool.

GENERAL SAFETY INSTRUCTIONS

A. Never allow children to use the tool.

B. Beware of overhead power lines.

C. Do not use the tool while people or children are nearby. Keep at

least 15 metres away.

D. Dress properly! Do not wear loose clothing or jewellery, which can be

caught in moving parts.

E. Use of sturdy gloves, nonskid footwear hearing protection and safety

glasses.

F. Use extra care when handling fuels. They are ammable and the

vapours are explosive.

8

G. The following points should be observed:

• Use only an approved fuel container.

• Never remove the fuel cap or add fuel with the engine

running.

• Allow engine and exhaust components to cool down before

refuelling.

• Do not smoke.

• Never refuel indoors.

• Never store the tool or fuel container inside where there is an

open ame, such as near a water heater.

• If fuel is spilled, do not attempt to start the engine, move the

tool away from the spillage before starting.

• Always replace and securely tighten the fuel cap after

refuelling.

H. If the tool starts making any unusual noise or vibration. Turn OFF the

engine and allow the tool to stop and take the following steps:

• Inspect for damage:

• Check for and tighten any loose parts;

• Have any damaged parts replaced repaired with parts having

equivalent specications

WHEN USING THE TOOL

A. Stop the engine before:

• Cleaning or when clearing a blockage.

• Checking, carrying out maintenance or working on the tool.

• Adjusting the working position of the cutting device.

• Leaving the tool unattended.

B. Ensure that the tool is correctly located in a designated working

position before starting the engine.

C. While operating the tool always ensure that the operating position is

safe and secure, especially when using steps or a ladder.

D. To reduce re hazards keep the engine and silencer free of debris,

leaves and excessive lubricant.

E. Always ensure that all handles and guards are tted when using the

tool. Never attempt to use an incomplete tool or one tted with an

unauthorised modication.

F. Always be aware of your surroundings and stay alert for possible

hazards of which you may not be aware due to the noise of the tool.

G. Keep fuel in a suitable container specially made for this purpose.

9

WARNING! Dress appropriately.

WARNING! Beware of kickback.

ADDITIONAL SAFETY RULES FOR PETROL BRUSH CUTTER

A. Always use the brush cutter with the shoulder strap.

B. Do NOT use saw blades. Use only blades designed for use with

brush cutters.

C. Do not operate with loose clothing or long hair. These can be sucked

into the air intake of the tool.

D. While using, always wear sturdy footwear and long trousers. Do not

operate the equipment with bare feet or open sandals.

E. Do not operate in a hazardous location. Such areas include where

there is a risk of explosion of fumes, leaking gas or explosive dust.

F. Do not operate in a conned area. Exhaust gases, smoke or fumes

could reach dangerous concentrations.

G. Protect your tool. This tool is NOT WEATHERPROOF and should

not be exposed to direct sunlight, high ambient temperature and

damp, wet or high humidity conditions.

H. Do not smoke or use a mobile phone while refuelling. This is

potentially dangerous as it may ignite the fuel and cause an

explosion.

I. Take care not to spill fuel. When refuelling the tool ensure that the

engine has been switched o. Prevent the spilling of fuel as this

may also ignite with the hot engine. Never refuel whilst the engine is

running.

J. Be careful where you store the tool. Store the tool in a dry area away

from ammable liquids.

K. Keep your distance. The tool emits exhaust fumes.

L. Ensure you use fuel oil mix. Ensure that you mix 40 parts unleaded

fuel to 1 part two stroke oil, if not the engine will overheat and cause

damage to your tool.

M. Never ll fuel tank indoors.

KICKBACK

Take care using the metal blade with the tool. Kickback is a reaction that

occurs when the blade hits objects that it can not cut. This can make the

blade push away from the object or run along the object. This reaction can be

intense enough to lose control of the tool and can occur without a warning.

The operator should cut from right to left to minimize the chance of kickback.

10

N. Never ll fuel tank when engine is running or hot.

O. Stop the engine before re-fuelling.

P. Stop the engine and disconnect the spark plug wire If the tool starts

to vibrate abnormally (nd and remove the cause of the vibration

immediately).

Q. Reduce the throttle before turning o the engine.

R. The user is responsible for the safety of other people, animals and

objects in the working area. Keep people, children and domestic

animals at a safe distance while the tool is in use.

PREPARATION

BEFORE THE BRUSH CUTTER CAN BE USED IT REQUIRES

SOME ASSEMBLY.

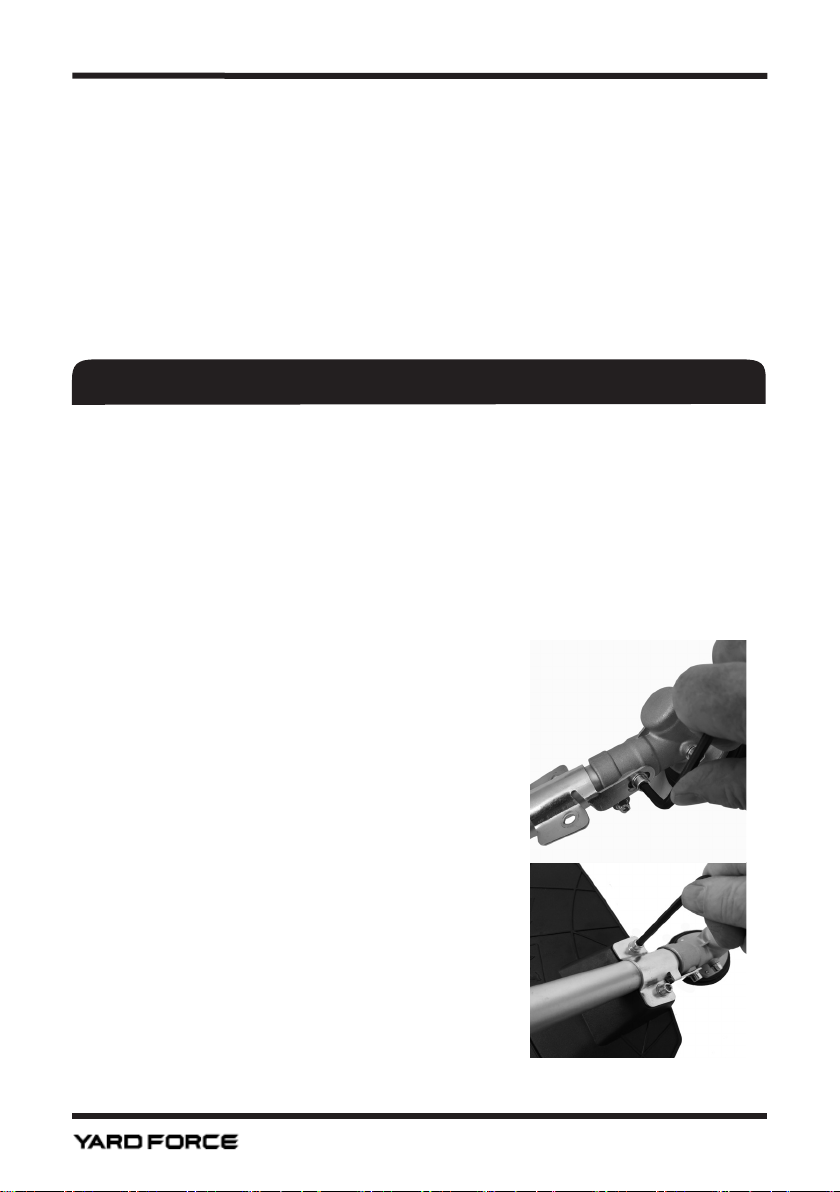

INSTALLING THE GUARD

●With the 5 mm Hex key. Remove the

two screws from the top of the guard

and the one on the side of the cutting

head.

● Place the Bracket (H) on the top of the

shaft and reinsert and tighten the screw

in the cutting head.

● Hold the Guard (D) underneath the

bracket, insert the two screws through

the bracket in to the holes in the guard

and retighten rmly.

Table of contents