YASKAWA L1000A Series User manual

MANUAL NO. SIEP YEUOCL1 01A

CANopen-Lift

Communication Option

Communication Option Card for Lift Inverter

Drive YASKAWA L1000A

Installation Manual

Type: SI-L3

This Page Intentionally Blank

2YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 3

Table of Contents

1. Preface and General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About Terms and Abbreviations in This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About Registered Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Explanation of Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Exclusion of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About This Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Applicable Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Receiving the Option Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Content and Packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. CANopen Lift Option Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CANopen Lift Option SI-L3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CANopen-Lift Option Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

RUN LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ERR LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Indicator Flash Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Communication Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Communication Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Network Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5. Mechanical & Electrical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before Installing the Option Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Option on a L1000A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6. CANopen-Lift Option Related Drive Parameters . . . . . . . . . . . . . . . . . . . . . 14

7. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Drive-Side Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Minor Faults/Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

8. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1 Preface and General Precautions

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 5

1 Preface and General Precautions

This chapter describes important safety precautions regarding the use of this product. Failure to follow these

precautions may result in serious injury or death, and may lead to damage to this product or related devices and

systems. Yaskawa shall not be held responsible for any injury or equipment damage as a result of failure to

observe the precautions and instructions contained in this manual.

◆Receiving

This instruction manual contains the information necessary to use the product correctly. Thoroughly read this

manual before installing, wiring, operating, or performing maintenance and inspections. Make sure to read and

understand the safety information and precautions before using the product.

■About Terms and Abbreviations in This Document

Representations Used in This

Manual Description

CANopen-Lift Option Yaskawa CANopen Lift communication option card

Online-DRV Processing mode, process (ctrl/resp) data is active

Online-DRVMB Processing mode, process resp data is active, ctrl data is on hold (until MEMOBUS process is

complete)

Online-PRG Processing mode, NO process (ctrl/resp) data is active

Host YASKAWA inverter drive for Lift L1000A

LED Light Emitting Diode

OPT, Option The unit described in this document

INV, Inverter Inverter drive

PCB Printed Circuit Board

FCS Frame Check Sequence

INVR MEMOBUS register number

EDS Electronic Data Sheet file

■About Registered Trademarks

•CANopen® is a registered Community Trademark of CAN in Automation e.V.

•Other company names and product names that appear in this document are trademarks or registered trademarks

of the respective companies.

◆Safety

Read the safety guidelines carefully before installing, wiring, or operating this product.

■Explanation of Signal Words

DANGER Identifies a hazardous situation, which, if not avoided, will cause death or serious injury.

WARNING Identifies a hazardous situation, which, if not avoided, can cause death or serious injury.

CAUTION Identifies a hazardous situation, which, if not avoided, can cause minor or moderate injury.

NOTICE Identifies a property damage message.

■General Safety Instructions

Yaskawa Electric manufactures and supplies electronic components for a variety of industrial applications. The

selection and application of Yaskawa products is the responsibility of the designer of the equipment or the

customer that assembles the final product. Yaskawa is not responsible for how our products are incorporated into

the final system design. In all cases, Yaskawa products should not be incorporated into a product or design as the

exclusive or sole safety control function. All control functions are designed to dynamically detect failures and

operate safely without exception. All products that are designed to incorporate parts manufactured by Yaskawa

must be provided to the end user and include proper warnings and instructions regarding their safe use and

1 Preface and General Precautions

6YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

operation. All warnings from Yaskawa must be promptly issued to the end user. Yaskawa offers warranties only

for the quality of our products, in compliance with standards and specifications that are described in the manual.

Yaskawa does not offer other warranties, either explicit or implied. Yaskawa assumes no responsibility for

personal injury, property damage or loss, or compensation for damage caused by the incorrect application of our

products.

Note:

Be aware that serious injury or death may result if the warnings described in this manual are not observed. Yaskawa assumes no

responsibility for injuries or equipment damage to your company or customers that are caused by a failure to observe the information

contained in this manual.

•Read this manual carefully when mounting, operating, and repairing AC drives and Communication options.

•Follow all warnings, cautions, and instructions.

•All work should be carried out by qualified personnel.

•Ensure the drive is installed to an area that matches the following conditions.

DANGER Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before

servicing, disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal

capacitor stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage

decreases below 50 Vdc. When all indicators are OFF, remove the covers before measuring for dangerous voltages to make

sure that the drive is safe. Failure to obey will cause death or serious injury.

WARNING Fire Hazard. Do not connect power supply wiring to drive output terminals U/T1, V/T2, and W/T3. Connect

power supply wiring to main circuit input terminals R/L1, S/L2, and T/L3. Failure to obey can cause death or serious injury.

WARNING Electrical Shock Hazard. Do not make changes to the drive body or drive circuitry. Failure to obey can cause

death or serious injury and will void warranty. Yaskawa is not responsible for changes to the product made by the user.

WARNING Electrical Shock Hazard. Only let authorized persons install, wire, maintain, examine, replace parts, and

repair the drive. Failure to obey can cause death or serious injury.

WARNING Electrical Shock Hazard. Always ground the motor-side grounding terminal. Contacting the motor case can

cause death or serious injury from incorrect equipment grounding.

WARNING Electrical Shock Hazard. Do not work on the drive or around the drive while wearing loose clothing or jewelry.

Tighten loose clothing and remove all metal objects such as watches or rings. Failure to obey can cause death or serious injury.

WARNING Electrical Shock Hazard. The leakage current of the drive will be more than 3.5 mA in drive models 2xxxB,

2xxxC, 4002B to 4371B, 4002C to 4371C (with built-in EMC filter turned ON) and 4389 to 4675. The IEC/EN 61800-5-1: 2007

standard specifies that users must wire the power supply to automatically turn off when the protective ground wire disconnects.

Users can also connect a protective ground wire that has a minimum cross-sectional area of 10 mm2(copper wire) or 16 mm2

(aluminum wire). Failure to obey these standards can cause death or serious injury.

WARNING Sudden Movement Hazard. Remove all persons and objects from the area around the drive, motor, and load

before starting Auto-Tuning. The drive and motor can start suddenly during Auto-Tuning and cause death or serious injury.

WARNING Sudden Movement Hazard. Remove all persons and objects from the area around the drive, motor, and

machine area and attach covers, couplings, shaft keys, and machine loads before energizing the drive. Failure to obey can

cause death or serious injury.

WARNING Fire Hazard. Do not use the main circuit power supply (Overcurrent Category III) at incorrect voltages. Make

sure that the drive rated voltage aligns with the power supply voltage before energizing the drive. Failure to obey can cause

death or serious injury.

WARNING Fire Hazard. Do not put flammable or combustible materials on top of the drive and do not install the drive

near flammable or combustible materials. Attach the drive to metal or other noncombustible material. Failure to obey can cause

death or serious injury.

WARNING Fire Hazard. Tighten all terminal screws to the correct tightening torque. Connections that are too loose or too

tight can cause incorrect operation and damage to the drive. Incorrect connections can also cause death or serious injury from

fire.

WARNING Electrical Shock Hazard. Do not cause a short circuit on the drive output circuit. Failure to obey can cause

death or serious injury.

WARNING Electrical Shock Hazard. Always use a type B Residual Current Monitor/Residual Current Device (RCM/RCD)

where a residual current operated protective or monitoring device protects against direct or indirect contact as specified by IEC/

EN 60755 The drive can cause a residual current with a DC component in the protective earthing conductor. Failure to obey can

cause death or serious injury.

WARNING Electrical Shock Hazard. Ground the neutral point on the power supply of drive models 2xxxB/C and 4xxxA/B/

C to comply with the EMC Directive before turning on the EMC filter or if there is high resistance grounding. If the EMC filter is

switched ON without the neutral point being grounded or if there is high resistance grounding, it can cause death or serious

injury.

2 Product Overview

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 7

WARNING Electrical Shock Hazard. Do not immediately energize the drive or operate peripheral devices after the drive

blows a fuse or trips an RCM/RCD. Wait for the time specified on the warning label at a minimum and make sure that all

indicators are OFF. Then check the wiring and peripheral device ratings to find the cause of the problem. Contact Yaskawa

before energizing the drive or peripheral devices if the cause is not known. Failure to obey can cause death or serious injury

and damage to the drive.

WARNING Fire Hazard. Install sufficient branch circuit short circuit protection as specified by applicable codes and this

manual. The drive is suited for circuits that supply not more than 100,000 RMS symmetrical amperes, 240 Vac maximum (200 V

Class), 480 Vac maximum (400 V Class). Failure to obey can cause death or serious injury.

CAUTION Burn Hazard. Do not touch a hot drive heatsink. De-energize the drive, wait 15 minutes minimum, and make

sure that the heatsink is cool to replace the cooling fans. Failure to obey can cause minor to moderate injury.

NOTICE Observe correct electrostatic discharge (ESD) procedures when touching the drive and circuit boards. Failure

to obey can cause ESD damage to the drive circuitry.

NOTICE Do not connect or disconnect the motor from the drive while the drive is supplying voltage. Incorrect

equipment sequencing can cause damage to the drive.

NOTICE Do not do a withstand voltage test or Megger test on the drive. Failure to obey can cause damage to the drive.

NOTICE Do not connect or operate damaged equipment or equipment with missing parts. Failure to obey can cause

damage to the drive and connected equipment.

NOTICE Install fuses and an RCM/RCD. Failure to obey can cause damage to the drive.

NOTICE Do not use unshielded wire for control wiring. Use shielded, twisted-pair wires and ground the shield to the

ground terminal of the drive. Failure to obey can cause electrical interference and unsatisfactory system performance.

NOTICE Make sure that all connections are correct after you install the drive and connecting peripheral devices.

Failure to obey can cause damage to the drive.

■Intended Use

This communication option card is electrical equipment intended to enable Yaskawa drives to communicate with

an additional fieldbus system for commercial use. Do not use this product for any other purpose.

1. Read and understand all safety precautions.

2. Wire and ground the drive and communication option card in accordance with all applicable standards and

safety precautions.

3. Firmly attach all parts and protective covers.

4. Always use the product in the proper environmental conditions as specified in this manual.

DANGER Electrical Shock Hazard. Make sure that all electrical connections are correct and install all drive covers

before energizing the drive. Use terminals for their intended function only. Incorrect wiring or ground connections, and incorrect

repair of protective covers can cause death or serious injury.

WARNING Electrical Shock Hazard. Do not make changes to the drive body or drive circuitry. Failure to obey can cause

death or serious injury and will void warranty. Yaskawa is not responsible for changes to the product made by the user.

◆Exclusion of Liability

This product is not designed and manufactured for use in life-support machines or systems.

Contact a Yaskawa representative or your Yaskawa sales representative if you are considering the application of

this product for special purposes, such as machines or systems used for passenger cars, medicine, airplanes and

aerospace, nuclear power, electric power, or undersea relaying.

WARNING Injury to Personnel. Yaskawa manufactured this product with strict quality-control guidelines. Install applicable

safety devices to minimize the risk of accidents when installing the product where its failure could cause a life-or-death situation,

loss of human life, or a serious accident or physical injury.

2 Product Overview

◆About This Product

The CANopen-Lift Communication Option (Model: SI-L3) is an option card designed to connect the Yaskawa

inverter drive for Lift L1000A to an CANopen-Lift network. Using this option card and an CANopen-Lift

controller you can:

•Operate the inverter drive for Lift

•Monitor the inverter drive for Lift operation status

3 Receiving

8YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

•Read or modify inverter drive for Lift parameters.

The CANopen-Lift Option supports the following communication profiles:

•CiA-301 Ver. 4.02

•CiA-417 Ver. 2.2.0, Profile Velocity and Profile Position

◆Applicable Models

The option can be used with the drive models in Table 2.1:

Table 2.1 Applicable Models

Option Card Model Drive Series Software Version

SI-L3 L1000A For L1000A 400V class: VSA923400 and higher

For software version, see “PRG”on the nameplate of the drive or regenerative unit.

3 Receiving

This instruction manual contains the information necessary to use the product correctly. Thoroughly read this

manual before installing, wiring, operating, or performing maintenance and inspections. Make sure to read and

understand the safety information and precautions before using the product.

◆Receiving the Option Card

Please perform the following tasks after receiving the Communication Option card:

•Inspect the Communication Option card for damage. If the Communication Option card appears damaged upon

receipt, contact the shipper immediately.

•Verify receipt of the correct model by checking the information on the PCB.

•If you have received the wrong option card model or the Communication Option card does not function

properly, contact your supplier.

◆Content and Packaging

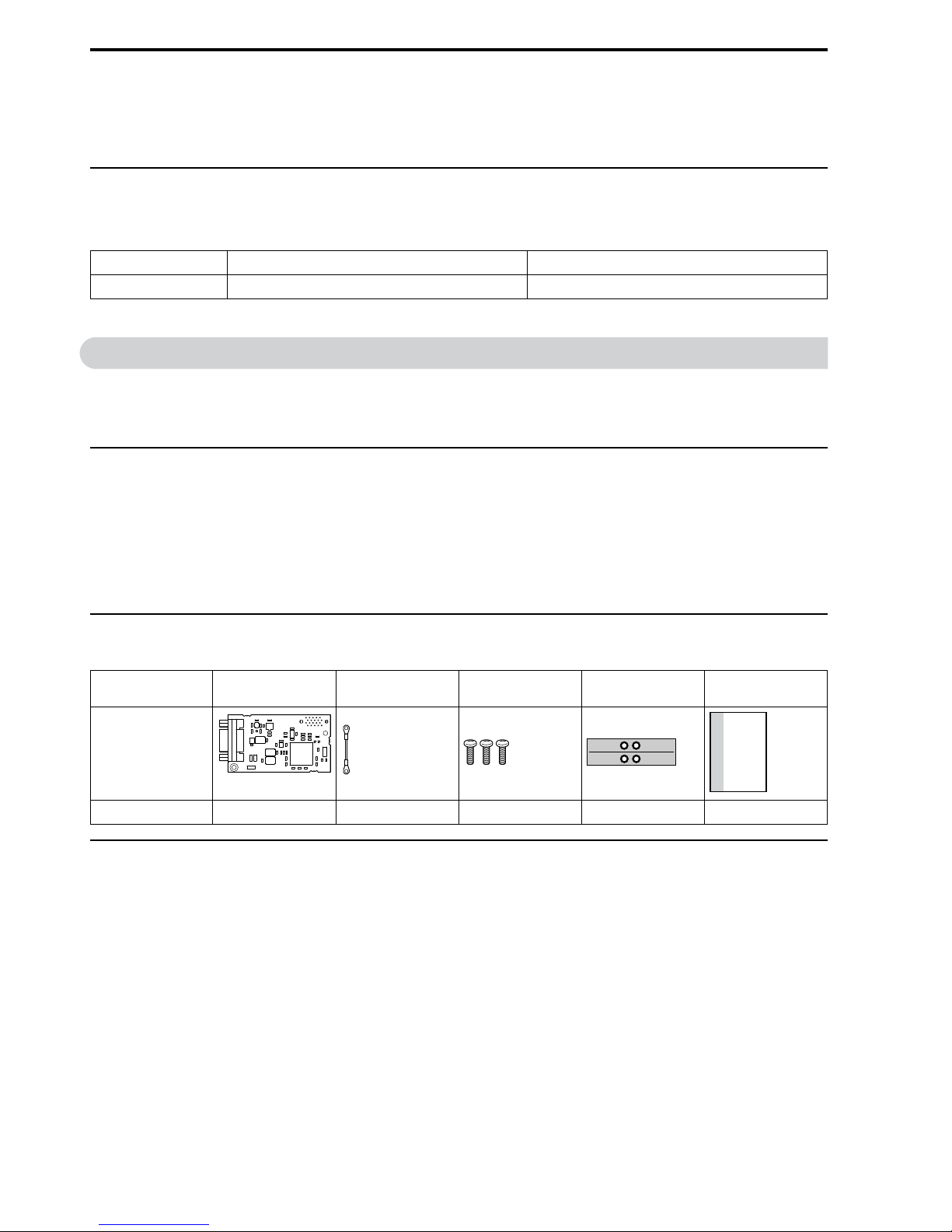

Table 3.1 Option Package Contents for SI-L3 (Inverter Drive for Lift L1000A)

Description Option Card Ground Cables Screws (M3) LED Label Installation

Manual

Illustration

Quantity 1 1 3 1 1

◆Tools Required

A Phillips screwdriver PH1(#1) or PH2(#2) is required to install the Communication Option card.

Note:

Tools required to prepare communication network cables for wiring are not listed in this manual.

ERR RUN

MANUAL

4 CANopen Lift Option Components

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 9

4 CANopen Lift Option Components

◆CANopen Lift Option SI-L3

A - Communication cable connector

(9 pin D-sub)

B - Connector (CN5)

C - Installation hole

D - LED (RUN)

E - LED (ERR)

F - Model number

G - Ground terminal (installation

hole)

Figure 4.1 Option Card

◆CANopen-Lift Option Status LEDs

The CANopen-Lift Option has two LEDs that indicate the communication status.

■RUN LED

LED Color Display Meaning

RUN Green On The device is in Operational State.

Green Blinking The device is in Pre-Operational State.

Green Single flash The device is stopped.

Green Flickering Automatic bit rate detection in process.

■ERR LED

LED Color Display Meaning

ERR – Off Online.

Red Blinking Bus initialization failed.

Single flash A fault has occurred. Receiving CAN error frames.

Double flash Guard / Heartbeat has occurred.

Flickering Automatic bitrate detection in process.

Flickers with RUN LED alternatively.

On Bus off.

4 CANopen Lift Option Components

10 YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

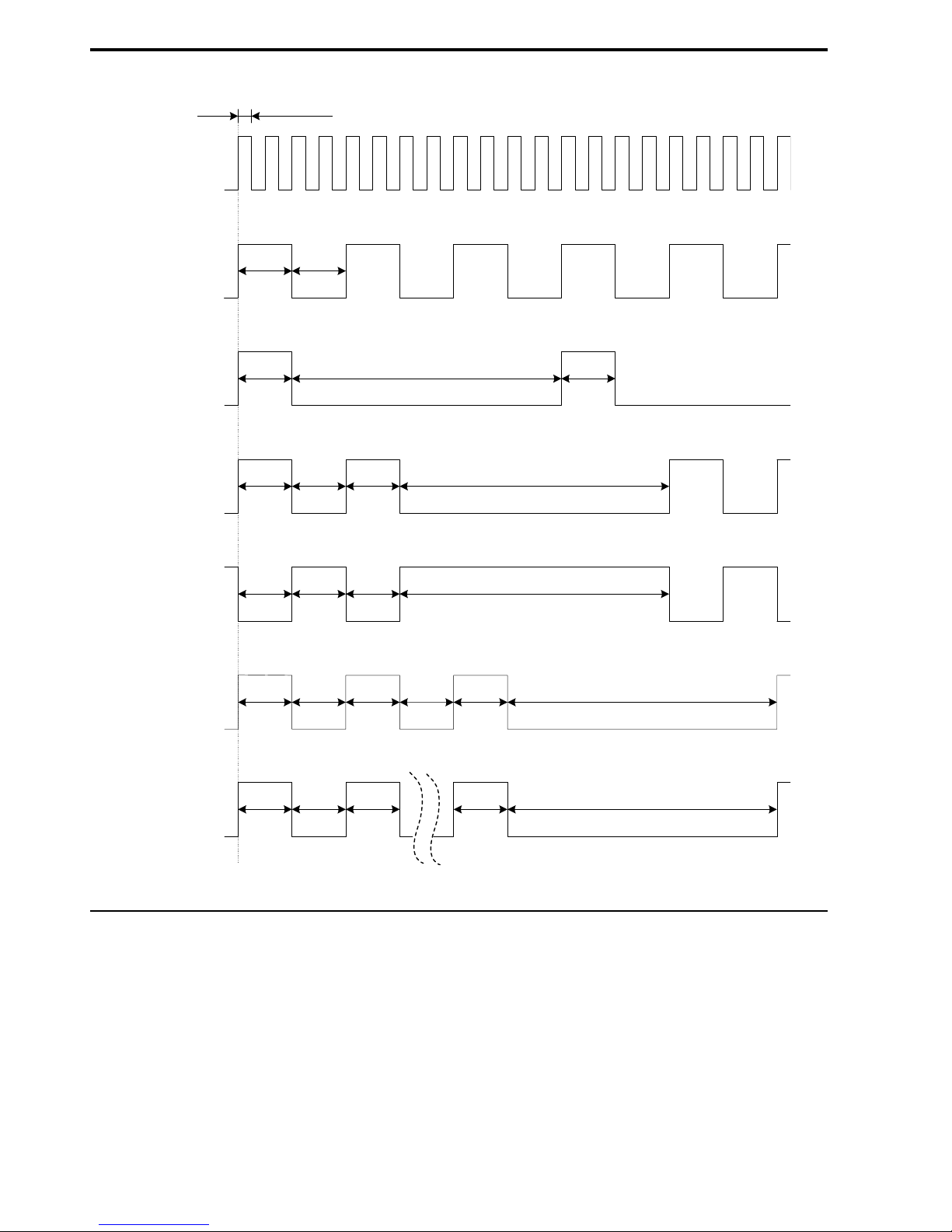

■Indicator Flash Rates

Figure 4.2 Meaning of LED Flash Rates

◆Communication Connector

The Communication Option card is connected to the network using a 9 pin D-sub connector.

flickering

on

50 ms

200 ms

200 ms

200 ms 200 ms 200 ms

200 ms 200 ms 200 ms

200 ms 200 ms 200 ms

200 ms 200 ms 200 ms

200 ms 200 ms

200 ms

1 2 n

200 ms1000 ms

1000 ms

1000 ms

1000 ms

1000 ms

200 ms

off

on

off

on

off

on

off

on

off

on

off

on

off

blinking

single

flash

double

flash

triple

flash

n flashes

inverted

double

flash

4 CANopen Lift Option Components

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 11

Table 4.1 Pin Assignment

Connector Pin Signal Description

1 – –

2 CAN_L CAN_L bus line (dominant low)

3 CAN_GND CAN ground

4 – –

5 CAN_SHLD CAN shield

6 – –

7 CAN_H CAN_H bus line (dominant high)

8 – –

9 – –

– CAN_SHLD CAN shield

■Communication Cable

Connect the CANopen-Lift option card to the network using a 9 pin D-sub connector wired like shown below.

Figure 4.3 Wiring Diagram

Note:

The FE terminal on the Communication Option must be connected to the drive ground terminal using the delivered ground wire.

■Network Termination

Both ends of the CANopen network have to be terminated with a 120 Ohm resistor. If the CANopen option is the

last node in the network, make sure to apply a termination resistor as shown below, because the CANopen option

does not have a built-in termination resistor:

Figure 4.4 Termination Resistor

6

7

8

9

1

2

3

4

5

120 Ω

5 Mechanical & Electrical Installation

12 YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

Note:

The FE terminal on the Communication Option must be connected to the drive ground terminal using the delivered ground wire.

5 Mechanical & Electrical Installation

◆Safety Precautions

DANGER Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before

servicing, disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal

capacitor stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage

decreases below 50 Vdc. When all indicators are OFF, remove the covers before measuring for dangerous voltages to make

sure that the drive is safe. Failure to obey will cause death or serious injury.

WARNING Electrical Shock Hazard. Do not operate equipment when covers are missing. Some figures in this section

include drives without covers or safety shields to more clearly show the inside of the drive. Replace covers and shields before

operation. Use drives only as specified by the instructions. Failure to obey can cause death or serious injury.

WARNING Electrical Shock Hazard. Do not work on the drive or around the drive while wearing loose clothing or jewelry.

Tighten loose clothing and remove all metal objects such as watches or rings. Failure to obey can cause death or serious injury.

WARNING Electrical Shock Hazard. Do not remove covers or touch circuit boards while the drive is energized. Failure to

obey can cause death or serious injury.

WARNING Electrical Shock Hazard. Only let authorized persons install, wire, maintain, examine, replace parts, and

repair the drive. Failure to obey can cause death or serious injury.

WARNING Electrical Shock Hazard. Do not make changes to the drive body or drive circuitry. Failure to obey can cause

death or serious injury and will void warranty. Yaskawa is not responsible for changes to the product made by the user.

WARNING Fire Hazard. Tighten all terminal screws to the correct tightening torque. Connections that are too loose or too

tight can cause incorrect operation and damage to the drive. Incorrect connections can also cause death or serious injury from

fire.

CAUTION Crush Hazard. Do not hold the drive by the front cover or terminal cover. Tighten the screws correctly before

moving the drive. Failure to obey can cause minor to moderate injury.

NOTICE Observe correct electrostatic discharge (ESD) procedures when touching the drive. Failure to obey can cause

ESD damage to the drive circuitry.

NOTICE Do not lift the drive with the cover removed. Failure to obey can cause damage to the drive board and terminal

block.

NOTICE Do not use unshielded wire for control wiring. Use shielded, twisted-pair wires and ground the shield to the

ground terminal of the drive. Failure to obey can cause electrical interference and unsatisfactory system performance.

NOTICE Do not change the drive circuitry. Failure to obey can cause damage to the drive and will void warranty.

Yaskawa is not responsible for modifications of the product made by the user.

NOTICE Make sure that all connections are correct after you install the drive and connecting peripheral devices.

Failure to obey can cause damage to the drive.

◆Before Installing the Option Card

Prior to installing the Communication Option Card, wire the inverter drive and connect to the drive terminals. For

more information on wiring and connecting the inverter drive, refer to the manual packaged with the inverter

drive.

Verify that the inverter drive runs normally without the option installed.

◆Installing the Option on a L1000A

1. Turn off the power. Wait until the CHARGE LED turns off and then remove the cover. Refer to the drive

manual for direction on removing the front cover.

2. Plug the option card (E) to the CN5-A connector (C).

Fieldbus option cards must always be plugged into CN5-A connector.

3. Connect the ground wire (F) to option card and fix with screw (1).

Select shortest possible cable for ground connection.

5 Mechanical & Electrical Installation

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 13

4. Fix option card to the inverter with screw (2) additionally. Connect the ground wire (F) to inverter ground

terminal (D).

Note:

There are only two screw holes on the drive for ground terminals. If three different option cards are connected, two of the

ground wires will need to share the same ground terminal.

A - Connector CN5-C

B - Connector CN5-B

C - Connector CN5-A

D - Drive grounding terminal (FE)

E - Option cards

F - Ground wire

G - Opening for cable lines (use

cutter to create the opening)

H - Operator

I - LED labels

J - Front cover

Figure 5.1 Installing the Option Card

5. Prepare the 9 pin D-sub network cable connectors.

For inverter drives CIMR-Lx4F0002 to 0023: the network cable should be routed to the outside through

the openings at the left side (G) of the front cover. Make sure no sharp edges remain.

For Inverter drives 4F0031 to 0165: enough space to keep all wiring inside the unit is available.

A - Opening for network cables

(CIMR-Lx4F0002 to 0023)

B - Space for wiring (CIMR-Lx4F0031

to 0165)

Figure 5.2 Network Cable Routing

6. Plug in the 9 pin D-sub network cable connector to the option.

7. Reinstall the front cover back onto the drive as it was before.

8. Attach the LED label (I) as shown in Figure 5.1.

9. Switch on the drive power supply.

10. Set inverter parameter as follows:

F

A

E

H

I

B

C

D

G

J

2

1

ERR RUN

A B

6 CANopen-Lift Option Related Drive Parameters

14 YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

b1-01 to 6,

b1-02 to 6,

H5-13 to 5.

11. Powercycle the inverter drive.

◆EDS File

For easy network implementation of drives equipped with a Communication Option card, the EDS file (version

ESI_SIS3L_OPT_V_2_01_04 or later) can be obtained from these sources:

•Europe:

http://www.yaskawa.eu.com

•Japan:

http://www.e-mechatronics.com

•USA:

http://www.yaskawa.com

•Other areas: contact a YASKAWA representative

6 CANopen-Lift Option Related Drive Parameters

Some drive parameters have influence on some functions of the communication option card. Check these

parameters before starting network communications.

Table 6.1 Parameter Settings

No. Name Description Default

b1-01 Frequency Reference Selection Selects the frequency reference input source

0: Operator - Digital preset speed d1-01 to d1-17

1: Terminals - Analog input terminals

2: MEMOBUS/Modbus communications

3: Option card

4: Pulse Input (Terminal RP)

6: DCP/CANopen-Lift

1

b1-02 Run Command Selection Selects the run command input source

0: Digital Operator - RUN and STOP keys

1: Digital input terminals Sx

2: MEMOBUS/Modbus communications

3: Option card

6: DCP/CANopen-Lift

1

F6-01 Operation Selection after

Communications Error

Determines drive response when a bUS error is detected during

communications

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

3: Alarm Only *1

1

F6-02 External Fault Detection

Conditions (EF0)

Sets the condition for external fault detection (EF0)

0: Always detected

1: Detected only during operation

0

F6-03 Stopping Method for External

Fault from Communication

Option Board

Determines drive response for external fault input (EF0) detection

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

3: Alarm Only

1

7 Troubleshooting

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 15

No. Name Description Default

F6-08 Reset Communication Related

Parameters

Determines if communication-related parameters are set back to

their original default values when the drive is initialized.

0: Do not reset F6-xx and F7-xx parameters when the drive is

initialized using parameter A1-03.

1: Reset F6-xx and F7-xx parameters when the drive is initialized

using parameter A1-03.

Note:

Setting this parameter does not affect communication-related

parameters. Setting this parameter only determines if

communication-related parameters (F6-xx and F7-xx) are also

reset when A1-03 is used to initialize the drive.

0

F6-35 Node Address 0 to 126 2

F6-36 Communication Speed 0: Automatic Bit Rate Detection

1: 10 kbps

2: 20 kbps

3: 50 kbps

4: 125 kbps

5: 250 kbps

6: 500 kbps

7: 800 kbps

8: 1 Mbps

5

H5-13 Serial Comm Mode 0: DCP Communication Channel

1: Memobus/Modbus

3: DCP 3

4: DCP 4

5: CANopen-Lift

1

o1-03 Digital Operator Display

Selection

Sets the units to display the frequency reference and output

frequency.

0: 0.01 Hz

1: 0.01% (100% = E1-04)

2: r/min (enter the number of motor poles to E2-04). Relevant for

CiA-417.

3: User defined by parameters o1-10 and o1-11

*2

o1-20 Traction Sheave Diameter 100.0 to 2000.0 mm 400.0 mm

o1-21 Roping Ratio 1 to 4 2

o1-22 Mechanical Gear Ratio 0.10 to 100.0 In CLV mode:

14.00

In CLV PM

mode: 1.00

*1 If set to 3, then the drive will continue to operate when an EF0 fault is detected. Take proper safety measures, such as installing an

emergency stop switch.

*2 The default value depends on the drive used and/or the drive software version. For details refer to the technical manual for the drive.

7 Troubleshooting

◆Drive-Side Error Codes

Drive-side error codes appear on the drive’s digital operator.

◆Faults

This section gives information about the causes and possible solutions of faults. You must use the Fault Reset

operation to remove the fault before you can operate the drive. Use the information in this table to remove the

cause of the fault.

7 Troubleshooting

16 YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

Code Name Causes Possible Solutions

bUS Option Communication

Error

The drive did not receive a signal from

the controller.

The communications cable wiring is

incorrect.

Correct wiring errors.

There is a short circuit or the

communications cable is not connected.

•Repair short circuits and connect cables.

•Replace the defective communications cable.

Electrical interference caused a

communication data error.

•Examine the control circuit lines, main circuit

lines, and ground wiring, and decrease the

effects of electrical interference.

•Make sure that a magnetic contactor is not the

source of the electrical interference, then use a

Surge Protective Device if necessary.

•Use only the recommended cables or other

shielded line. Ground the shield on the controller

side or the drive input power side.

•Isolate the communication wiring from drive

power lines, and install a noise filter to the input

side of the power supply for communication.

•Decrease the effects of electrical interference

from the controller.

The option card is incorrectly installed

to the drive.

Correctly install the option card to the drive.

The option card is damaged. If the fault continues and the wiring is correct,

replace the option card.

CLoE CANopen Lift Operation

Error

Sequence error.

Invalid position data.

•Check shaft encoder.

•Check inverter and lift controller setup and

wiring.

oFA00 Option Not Compatible

with Port

The option card connected to connector

CN5-A is not compatible.

Connect the option card to the correct connector.

Note:

Encoder option cards are not compatible with

connector CN5-A.

oFA01 Option Fault/Connection

Error

The option card connected to connector

CN5-A is not compatible.

1. De-energize the drive.

2. Refer to the option card manual and correctly

connect the option card to the connector on the

drive.

oFA30 to

oFA43

Communication Option

Card Connection Error

(CN5-A)

A fault occurred in the option card. 1. De-energize the drive.

2. Make sure that the option card is correctly

connected to the connector.

3. If the problem continues, replace the option

card.

oFb00 Option Not Compatible

with Port

The option card connected to connector

CN5-B is not compatible.

Connect the option card to the correct connector.

Note:

DO-A3, AO-A3, PG-B3, and PG-X3 options

can connect to connector CN5-B. Use connector

CN5-C when connecting only one encoder

option card.

oFb02 Duplicate Options The same option cards or the same type

of option cards are connected to

connectors CN5-A, B, and C.

Connect the option card to the correct connector.

oFC00 Option Not Compatible

with Port

The option card connected to connector

CN5-C is not compatible.

Connect the option card to the correct connector.

Note:

AI-A3, DI-A3, and communication option cards

cannot be connected to the CN5-C connector.

oFC02 Duplicate Options The same option cards or the same type

of option cards are connected to

connectors CN5-A, B, and C.

Connect the option card to the correct connector.

PE1 Programming Error 1 Object content mapping was changed

from the default. A Node reset was sent

while the drive was running.

Stop the drive before performing Node reset.

8 Specifications

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 17

◆Minor Faults/Alarms

This section gives information about the causes and possible solutions when a minor fault or alarm occurs. Use

the information in this table to remove the cause of the minor fault or alarm.

Code Name Causes Possible Solutions

AEr Station Address Setting

Error

Option card node address is outside of

the acceptable setting range.

For CANopen communication, set F6-35

[CANopen Node ID Selection] correctly.

CALL Serial Comm Transmission

Error

The communications cable wiring is

incorrect.

Correct any wiring errors.

There is a short circuit or the

communications cable is not connected.

•Repair short circuits and connect cables.

•Replace the defective communications cable.

There was a programming error on the

controller side.

Examine communications at start-up and correct

programming errors.

The communications circuitry is

damaged.

•Do a self-diagnostics check.

•If the problem continues, replace the control

board or the drive. For information about

replacing the control board, contact Yaskawa or

your nearest sales representative.

The termination resistor setting for

MEMOBUS/Modbus communications

is incorrect.

On the last drive in a MEMOBUS/Modbus

network, set DIP switch S2 to the ON position to

enable the termination resistor.

EEP EEPROM Checksum Error Communication wiring is faulty, there is

a short circuit, or something is not

connected properly.

Correct any wiring errors.

EEPROM checksum error. •If these errors occur, the object dictionary will be

reset to its default values. After the object

dictionary has been changed and object

dictionary contents are then changed, execute a

Store Parameter command (Index = 1010 (Hex)).

•If the object dictionary has not been changed,

execute a Restore Parameter command (Index =

1011 (Hex)).

Programming error occurred on the

controller side.

Check communications at start-up and correct

programming errors.

Communications circuitry is damaged. •Perform a self-diagnostics check.

•If the problem continues, replace either the

control board or the entire drive. For instructions

on replacing the control board, contact Yaskawa

or your nearest sales representative.

8 Specifications

Item Specification

Model SI-L3

Communication Profile CiA-301 Ver. 4.02

CiA-417 Ver. 2.2.0, Profile Velocity and Profile Position

Connector 9 pin D-sub connector

Communication Speed 10 kbps to 1 Mbps

Ambient Temperature -10 °C to +50 °C

Humidity up to 95% RH (non-condensing)

Storage Temperature -20 °C to +60 °C

Area of Use Indoor (free of corrosive gas, airborne particles, etc.)

Altitude Up to 1000 m

18 YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual

Revision History

Date of

Publication

Revision

Number Section Revised Content

November 2017 ––First Edition

YASKAWA ELECTRIC SIEP YEUOCL1 01A CANopen-Lift Communication Option Installation Manual 19

CANopen-Lift Communication

Option

Communication Option Card for Lift Inverter Drive

YASKAWA L1000A

In the event that the end user of this product is to be the military and said product is to be

employed in any weapons systems or the manufacture thereof, the export will fall under the

relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations.

Therefore, be sure to follow all procedures and submit all relevant documentation according

to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and

improvements.

© 2017 YASKAWA Europe GmbH

YASKAWA Europe GmbH

MANUAL NO. SIEP YEUOCL1 01A <1>-0

Published in Germany January 2017

17-1

Original instructions

*SIEPYEUOCL101*

YASKAWA EUROPE GmbH

Hauptstraβe 185, 65760 Eschborn, Germany

Phone: +49-6196-569-500

E-mail: [email protected]

http://www.yaskawa.eu.com

DRIVE CENTER (INVERTER PLANT)

2-13-1, Nishimiyaichi, Yukuhashi, Fukuoka, 824-8511, Japan

Phone: +81-930-25-2548 Fax: +81-930-25-3431

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121, Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: +1-800-YASKAWA (927-5292) or +1-847-887-7000 Fax: +1-847-887-7310

http://www.yaskawa.com

Other manuals for L1000A Series

5

Table of contents

Other YASKAWA Inverter Drive manuals