CONTENTS

1 Standard Specifications ...................................................................................1

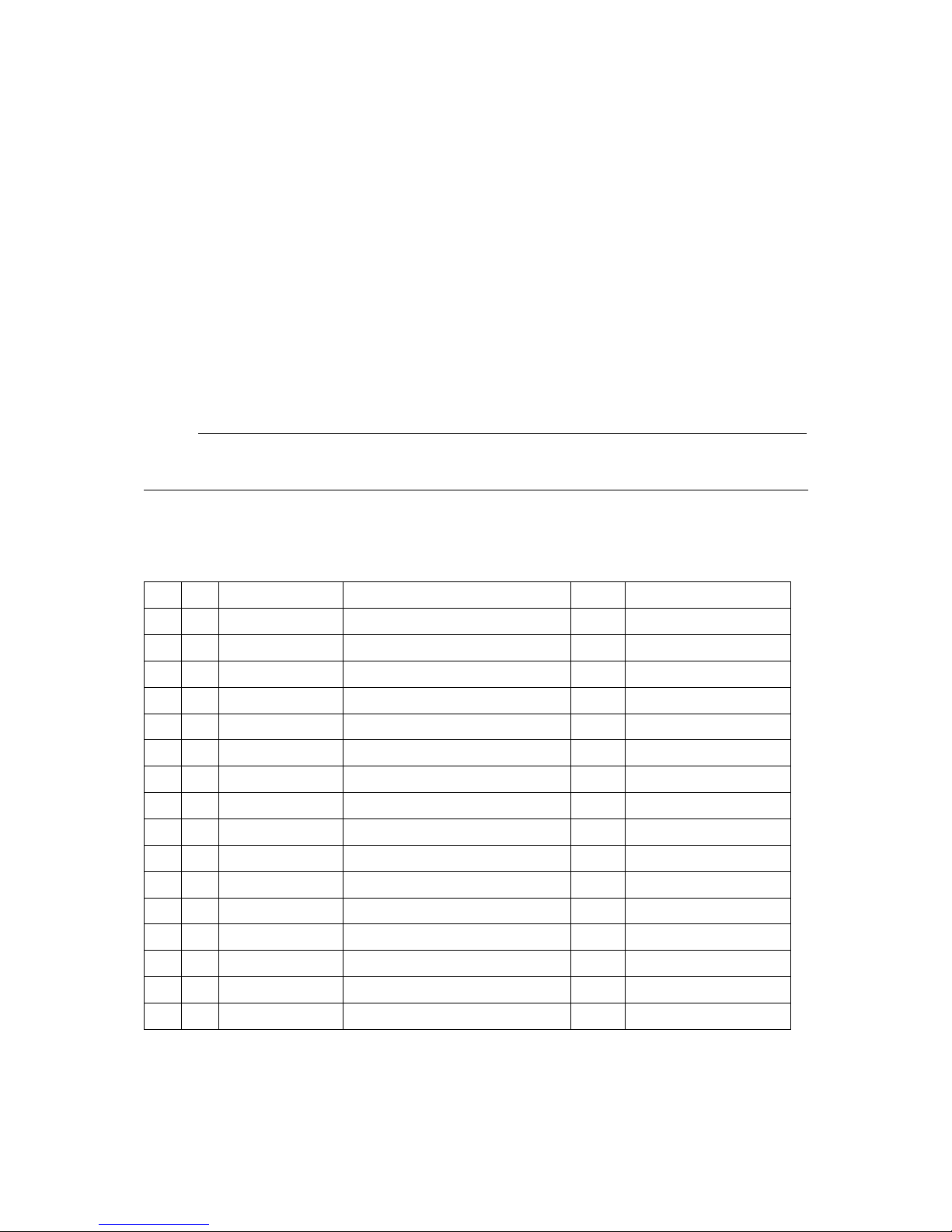

2 Kit Parts .............................................................................................................2

2-1 Basic Kit Set Contents..............................................................................2

2-2 Engine Parts ..............................................................................................2

1. Maintenance set (5VY-MAINT-70).......................................................2

2. Spark Plugs ........................................................................................3

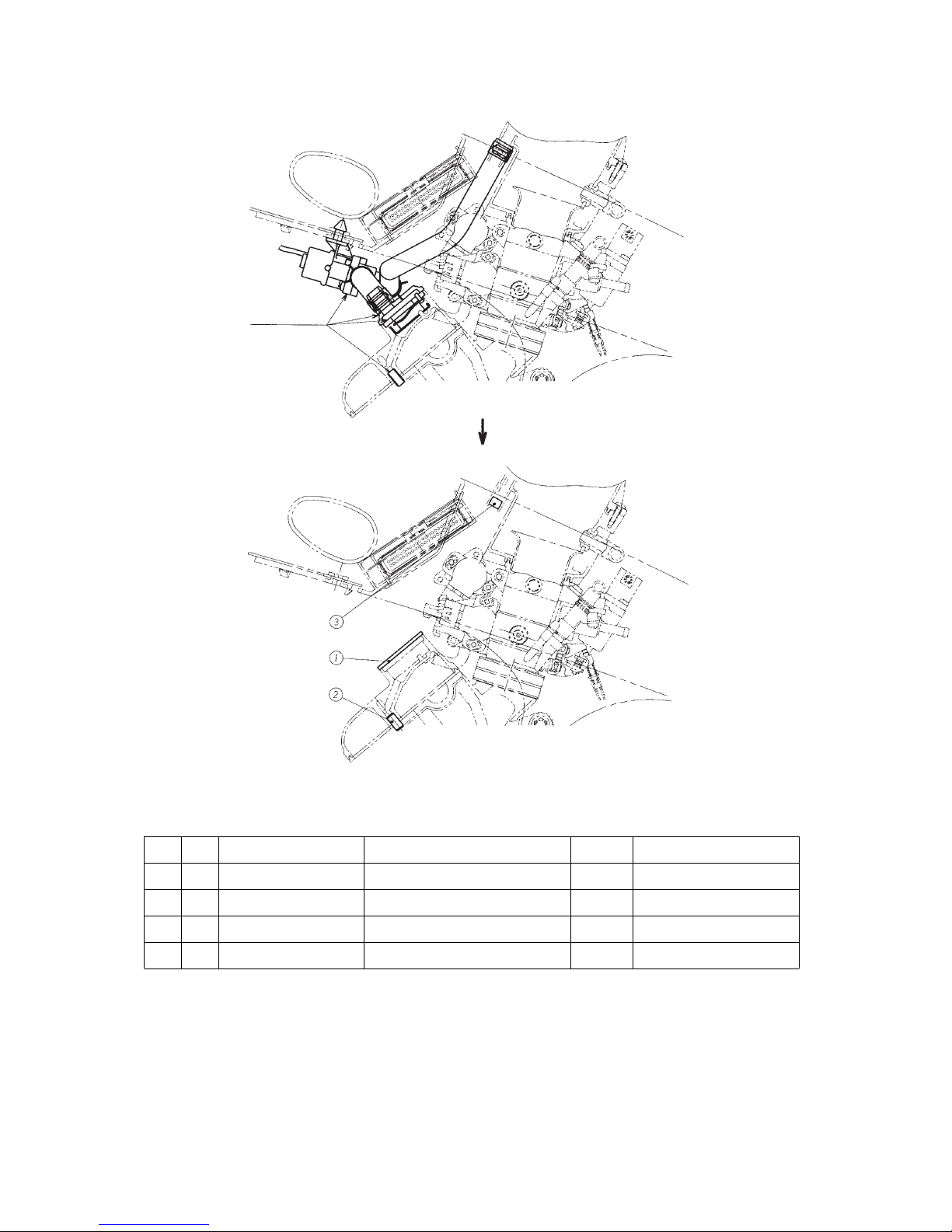

3. AIS Plug Set (5VY-A4890-70) .............................................................3

4. Gaskets...............................................................................................4

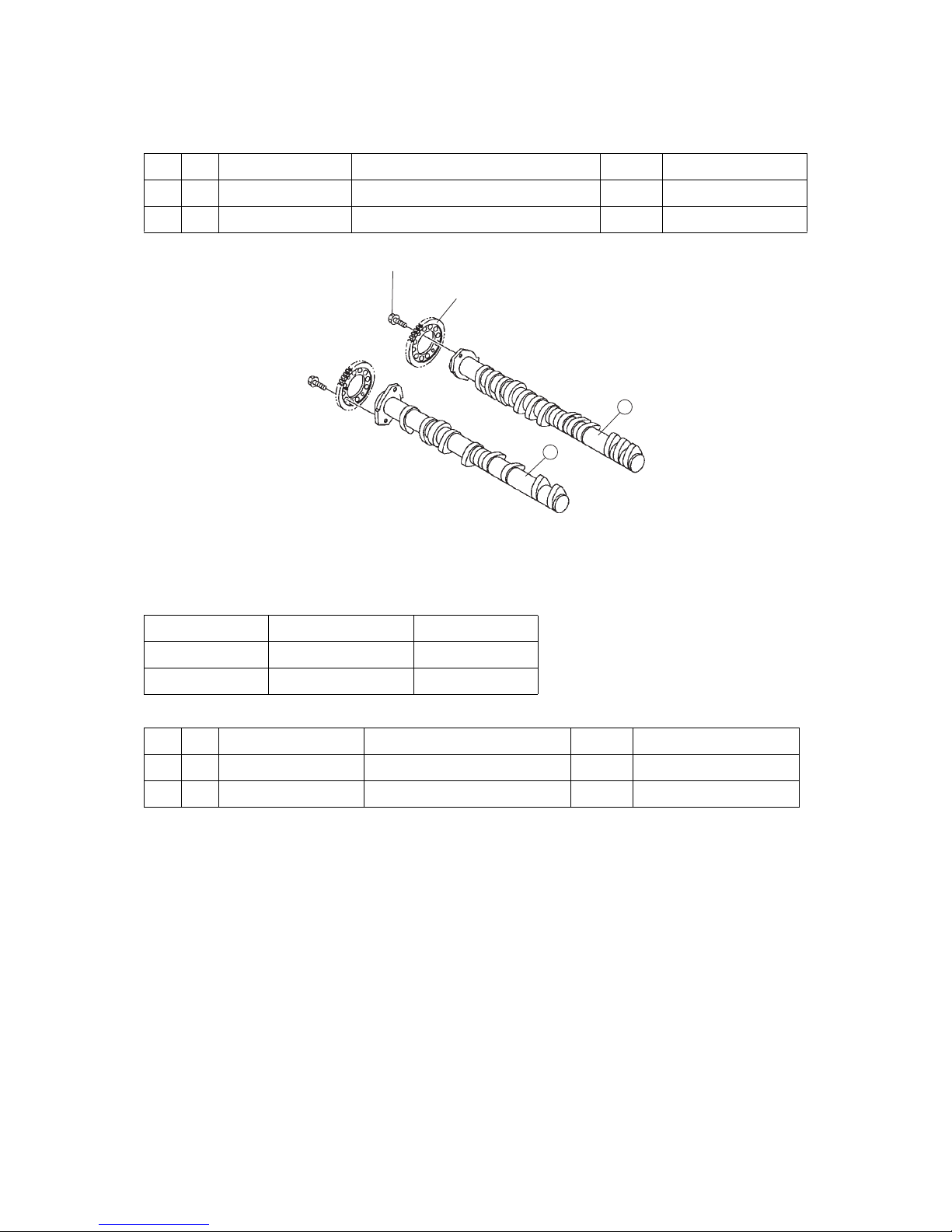

5. High-lift Camshaft, Valve Spring ........................................................5

6. Standard-lift Camshafts ....................................................................6

7. Flat Valve Set (5VY-A2100-70)............................................................7

8. Sub-radiator Set (5VY-A240A-70) ......................................................8

9. Funnel Set (5VY-A4460-70) ...............................................................9

10. Clutch Spring, Clutch Boss .............................................................10

11. ACM Rotor .......................................................................................11

12. Engine Control Unit (ECU) ................................................................12

13. Wire Harness ...................................................................................23

14. Headlight Harness Set (5VY-F4350-70) ...........................................23

2-3 Chassis Parts ..........................................................................................25

15. Oil Catcher Tank Set (5VY-C1707-70) .............................................25

16. Chassis Protector Set (5VY-C117G-70) ...........................................26

17. Rear Suspension Spring...................................................................26

18. Front Fork Spring Set .......................................................................27

19. Front Disk Assembly (5VY-2581T-70) ..............................................28

20. Front Wheel Attachment Set ............................................................29

21. Rear Arm Attachment Set, Rear Wheel Attachment Set .................30

22. Sprocket, Sprocket Nut....................................................................34

23. Throttle Set (5VY-C6300-70).............................................................34

24. Footrest Set (5VY-C7400-70)............................................................36

25. Front Stay Set (5VY-C8350-70) ........................................................38

2-4 Other.........................................................................................................39

26. Valve Seat Cutter Set........................................................................39