Wegj Install - Mar2007 Page 1 of 4

A division of Terry Young Ltd , New Zealand

INSTALLATION INSTRUCTIONS for

WEGJ 2000 FREESTANDING WOODBURNER

APRIL 2007

TESTED in compliance with AS/NZS 2918: 2001

A. Yunca recommends that competent trades persons carry out all installations (e.g. NZHHA

Registered Installer), to obtain maximum performance and safe, efficient heating.

B. A permit is required and we suggest you check with local building inspectors as by-laws do

vary from area to area.

Also notify your Insurance Company that a solid fuel heater has been installed.

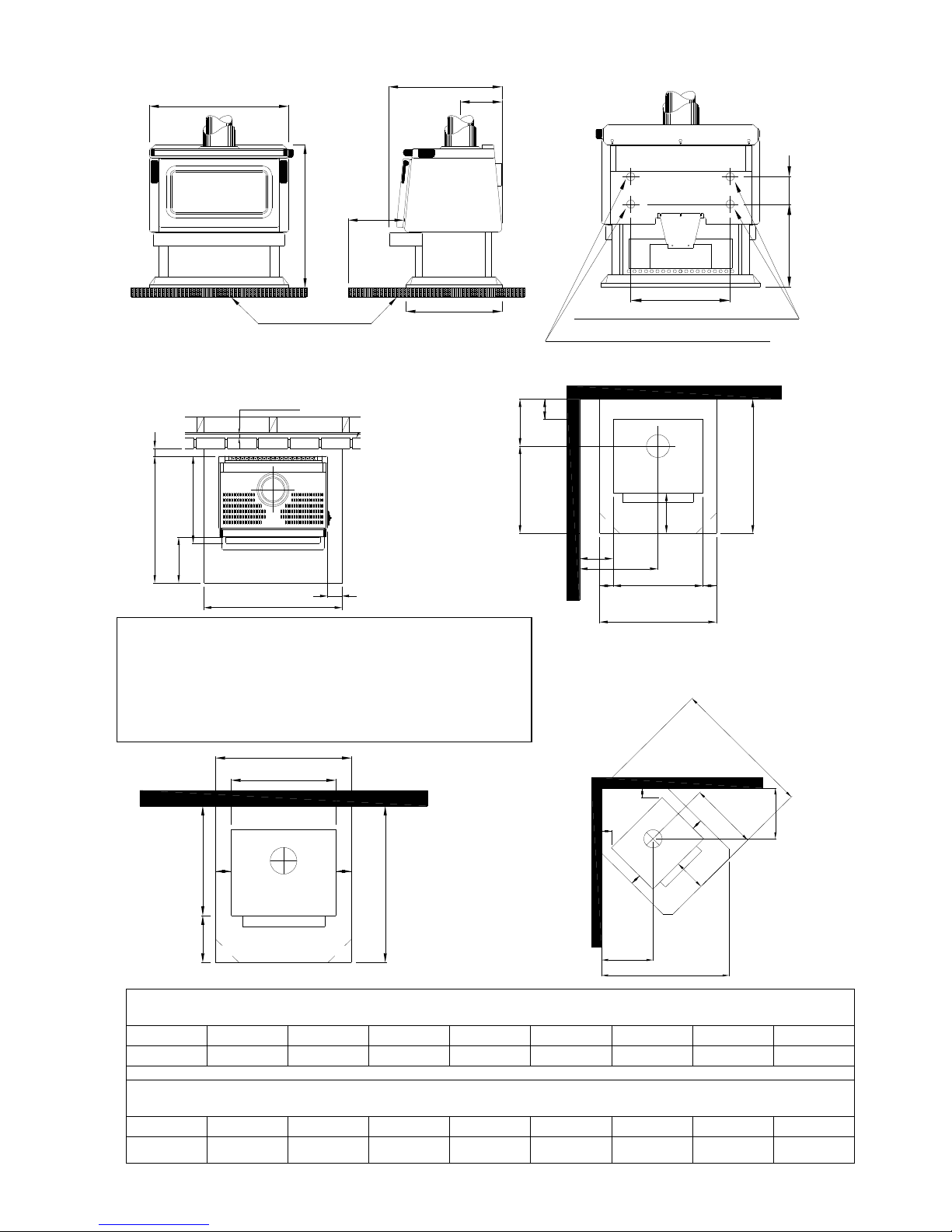

C. Floor Protector –

1. Must extend a minimum of 300mm in front of the door aperture.

2. Must extend at least 100mm from each side of the heater.

3. Ash Floor Protector must be constructed of non-combustible materials, with a

minimum thickness of 12mm.

D. Seismic restraint – Heater must be restrained from seismic movement as required by NZS

7421. 10mm diameter bolting holes in the rear corners allow restraint.

E. Manufacturers recommended tested minimum clearances from combustible walls.

Tested to AS/NZS 2918 : 2001 by APPLIED RESEARCH SERVICES Clearance

Rear Clearance (with YUNCA flue shield fitted) 100mm

Side Clearance (with YUNCA flue shield fitted) 200mm

Corner Clearance (with YUNCA flue shield fitted) 30mm

Rear Clearance (without YUNCA flue shield) 350mm

Side Clearance (without YUNCA flue shield) 200mm

Corner Clearance (without YUNCA flue shield) 140mm

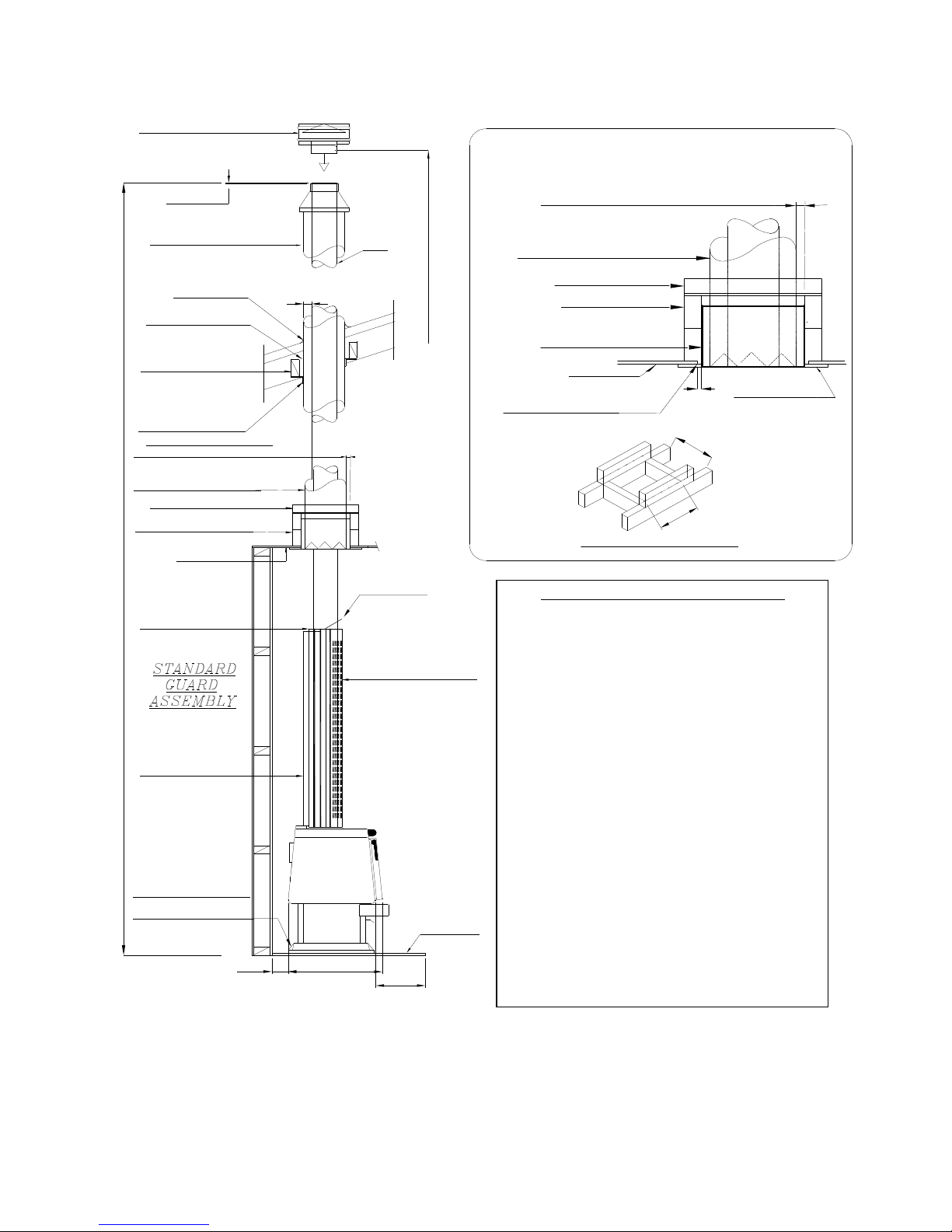

F. YUNCA Flue Kit (Tested to AS/NZS 2918:2001 Appendix F): FIG A, B & E

1. 4.2m x 150mm stainless steel flue. 4. 1 x insulation boundary shield.

2. 2.4m x 250mm galvanised liner. 5. 3 x spider brackets.

3. 1 x ceiling tile. 6. 1 x weather cap & cowl.

Please Note: All joints must be sealed with flue sealing compound. Use stainless steel

screws or rivets to join the flue pipe (three equally spaced places at each joint). The first

length of flue pipe must be screwed to flue spigot. The required minimum flue termination

height is 4.6 m above the floor protector.

G. WEGJ Flue Mounted Shield (Flue Guard) Kit (Tested to AS/NZS 2918:2001): FIG A

1 x 1200mm length lined back guard, plus an optional adjustable 900mm extension.

1 x 1200mm length perforated front guard.

1 x 1200mm length tertiary back guard with spacers.

1 x top front deflector shield (half round shaped, angled when installed).

Please Note: The minimum Flue Guard Height Is 1200mm.