Table of Contents

Disclaimer...........................................................................................................................................................1

Precautions.........................................................................................................................................................2

Installation..........................................................................................................................................................3

Operation............................................................................................................................................................4

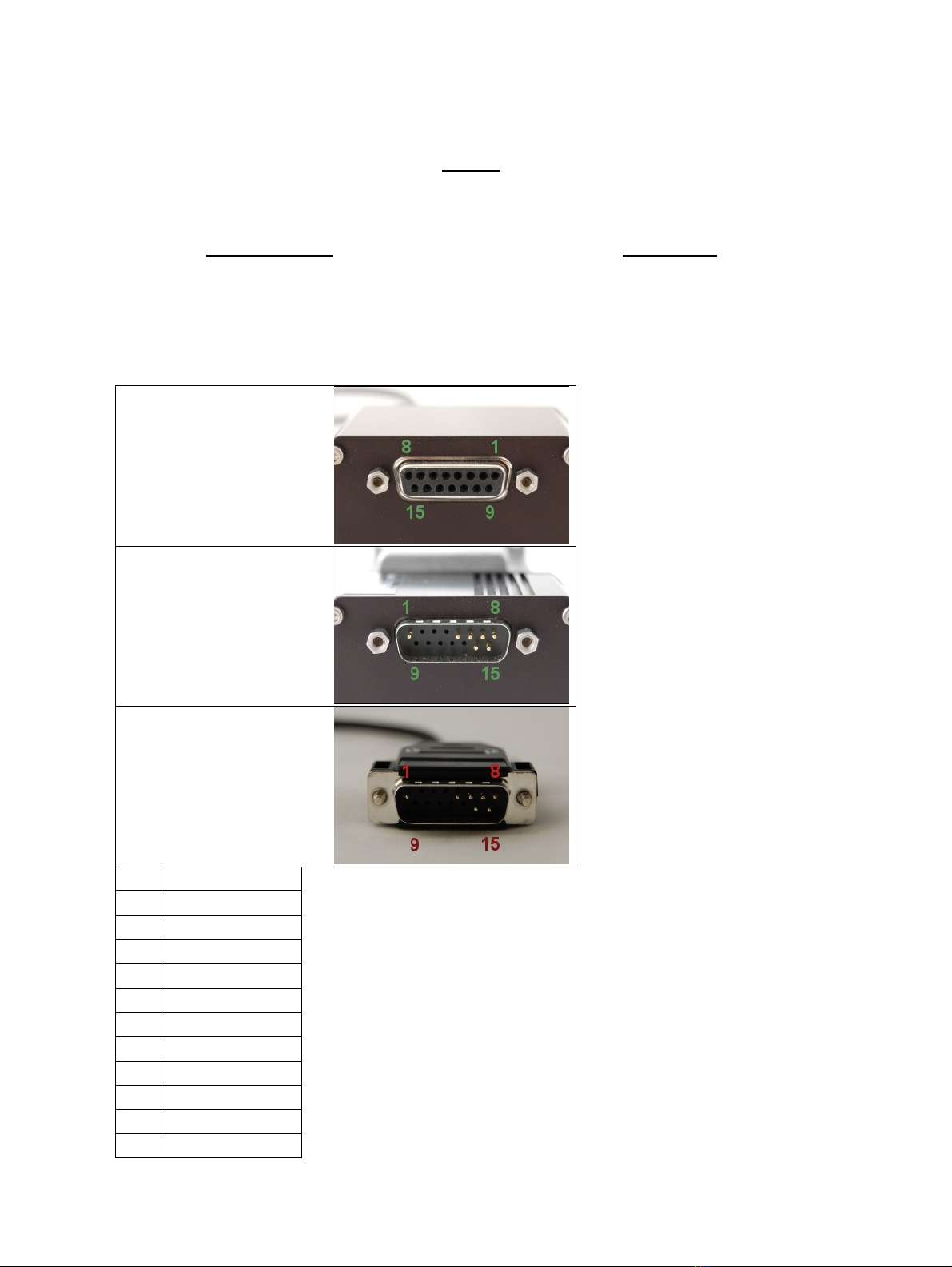

Pinout for D-sub 15 Connectors (A-series controllers and peripherals).................................................4

Motor................................................................................................................................................5

Alternate Controllers...............................................................................................................................5

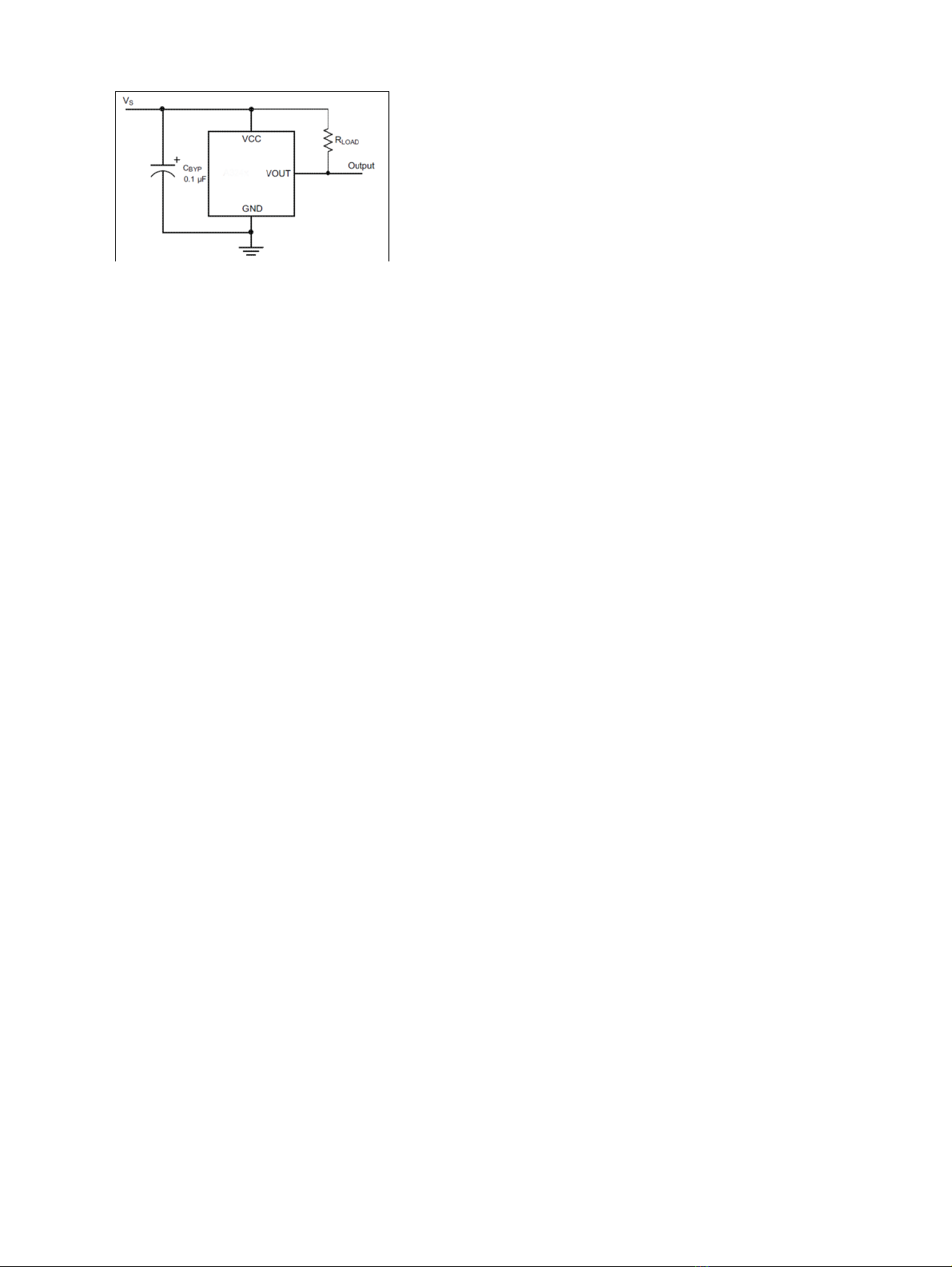

Home Sensor Wiring...............................................................................................................................5

Warranty and Repair........................................................................................................................................7

Standard products....................................................................................................................................7

Custom products.....................................................................................................................................7

How to return products...........................................................................................................................7

Email Updates....................................................................................................................................................8

Contact Information..........................................................................................................................................9

Group Specifications - LSA Series........................................................................................................10

Comparison - LSA Series......................................................................................................................11

i